GROUND MOUNT INSTALLATION MANUAL - 4

© 2019 IRONRIDGE, INC. VERSION 2.8

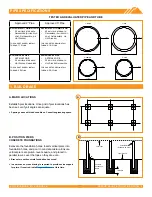

PIPe SPeCIFICATIONS

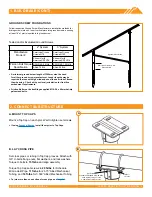

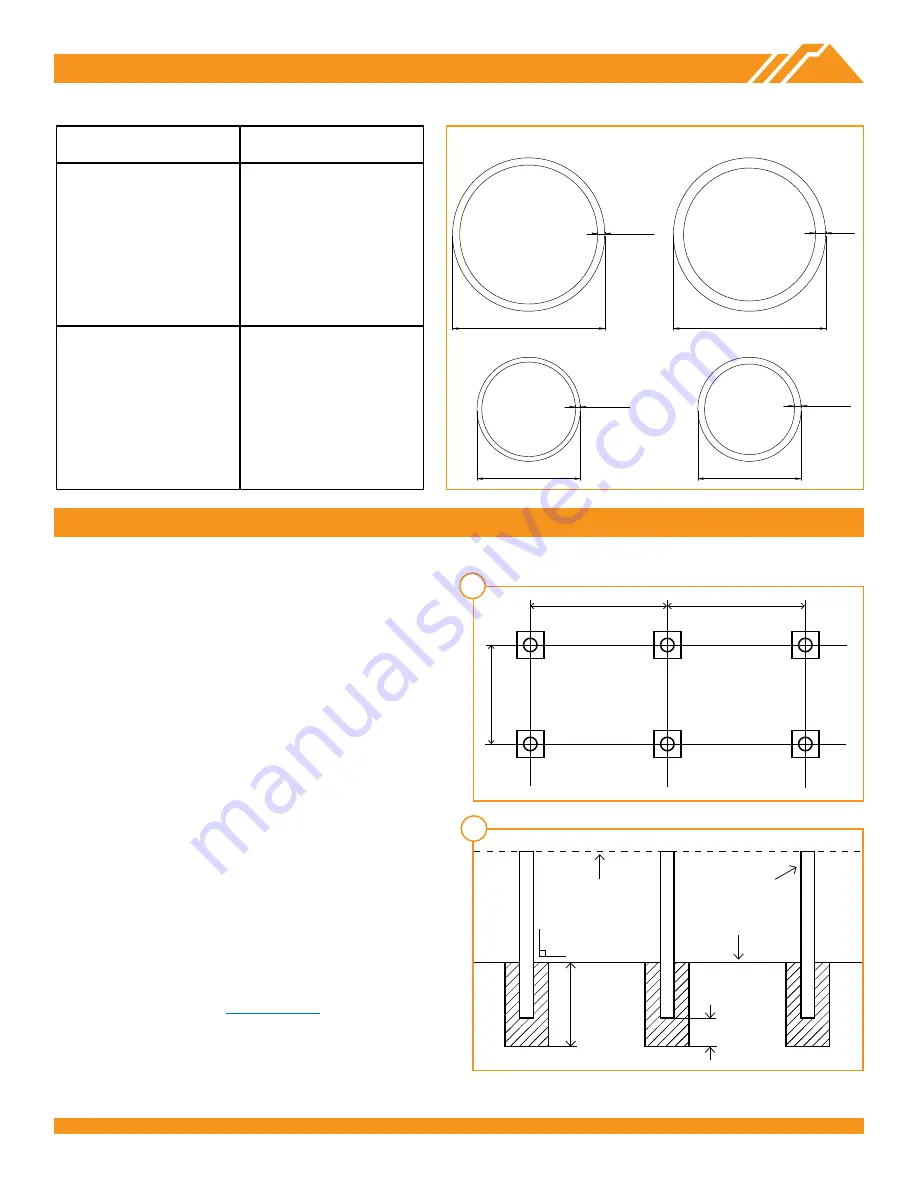

A. MARK LOCATIONS

Establish pier locations. Once grid of pier locations has

been set, verify all angles are square.

➢

Spacing varies with load conditions. Consult engineering specs.

B. POSITION PIeRS

CONCReTe FOUNDATIONS

Excavate the foundation holes. Insert vertical piers into

foundation holes, and pour in concrete mixture. Ensure

vertical piers are plumb, level, square, and placed in

parallel rows. Level the tops so they are even.

➢

Brace piers until concrete foundation has cured.

➢

In some cases, cross bracing is required to provide extra support

for piers. If required, install

Diagonal Braces

at this time.

A

B

Level Tops

Vertical Pier

(Schedule 40 Pipe)

Level Ground

90°

1/3 Depth

Concrete

Foundation

Depth

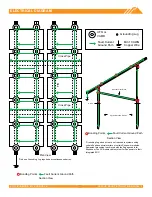

1. BUILD BASe

TeSTeD AND eVALUATeD PIPe AND TUBe

.216 in

3.5 in

3" PIPE

.154 in

2.375 in

3" pipe

.165 in

3.5 in

3" TUBING

.109 in

2.375 in

2" Tubing

Approved 2” Pipe

Approved 3” Pipe

ALLIeD MeCH TUBING 12 GA

•

50 ksi yield strength

•

Galvanized (Allied flot

-

coat, Gatorshield, or

Hot Dipped)

top cap set screw install

torque: 11-ftlbs

ALLIeD MeCH TUBING 8 GA

•

45 ksi yield strength

•

Galvanized (Allied flot

-

coat, Gatorshield, or

Hot Dipped)

top cap set screw install

torque: 16-ftlbs

SCHeDULe 40 PIPe

•

ASTM A53 GR B

•

35 ksi yield strength

•

Hot Dipped Galvanized

top cap set screw install

torque: 20-ftlbs

SCHeDULe 40 PIPe

•

ASTM A53 GR B

•

35 ksi yield strength

•

Hot Dipped Galvanized

top cap set screw install

torque: 20-ftlbs

2” PIPe

2” TUBING