GROUND MOUNT INSTALLATION MANUAL - 3

© 2019 IRONRIDGE, INC. VERSION 2.8

CHeCKLIST

IRONRIDGe COMPONeNTS

PRe-INSTALLATION

☐

Verify module compatibility. See

for info.

☐

Purchase 2” or 3” (NPS) ASTM A53 Grade B SCH

40 Pipe, galvanized to a min of ASTM A653 G90 or

ASTM A123 G35, or 2.375” or 3.500” (O.D.) Allied

Mechanical Tubing with Gatorshield or FlowCoat Zinc

Coating (ASTM A1057)

TOOLS ReQUIReD

☐

Post Hole Digger or Powered Auger

☐

Socket Drive (7/16”, 9/16”, and 1/2” Sockets)

☐

Torque Wrenches (0-240 in-lbs and 10-40 ft-lbs)

☐

Transit, String Line, or Laser Level

☐

3/16” Allen Head

TORQUe VALUeS

Top Cap Set Screws (3/16” Allen Head)

☐

2” or 3” NPS Schedule 40 Grade B Pipe: 20 ft-lbs

☐

2.375” OD Allied Mechanical Tubing: 11 ft-lbs

☐

3.500” OD Allied Mechanical Tubing: 16 ft-lbs

☐

Fot Ground Screw to Pipe Connection Hardware

☐

Top Cap U-Bolt Nuts (9/16” Socket): 15 ft-lbs

☐

Rail Connector Bracket Nuts (9/16” Socket): 21 ft-lbs

☐

Rail Connector U-Bolt Nuts (9/16” Socket): 60 in-lbs

☐

Grounding Lug Nuts (7/16” Socket): 80 in-lbs

☐

Grounding Lug Terminal Screws (7/16 Socket): 20 in-lbs

☐

Universal Fastening Objects (7/16” Socket): 80 in-lbs

☐

Diagonal Brace Set Screws (1/2” Socket): 15 ft-lbs

☐

Diagonal Brace Bolts (1/2” Socket): 40 ft-lbs

☐

Microinverter Kit Nuts (7/16” Socket): 80 in-lbs

☐

Frameless Module Kit Nuts (7/16” Socket): 80 in-lbs

➢

If using previous version of: Integrated Grounding Mid Clamps,

Grounding Lug, end Clamps, and expansion Joints please refer

to Alternate Components Addendum (Version 1.60).

➢

If installing on a low slope roof please refer to Ground Mount for

Flat Roof Applications Addendum (Version 2.60).

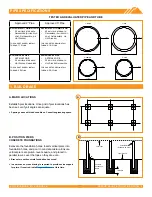

XR100 & XR1000 Rail

Rail Connector

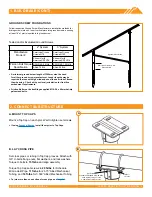

Top Cap

UFO

Diagonal Brace

Stopper Sleeve

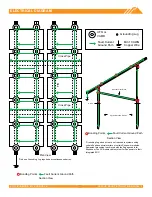

Grounding Lug

Microinverter Kit

Frameless Module Kit

Frameless End/Mid Clamp

CAMO

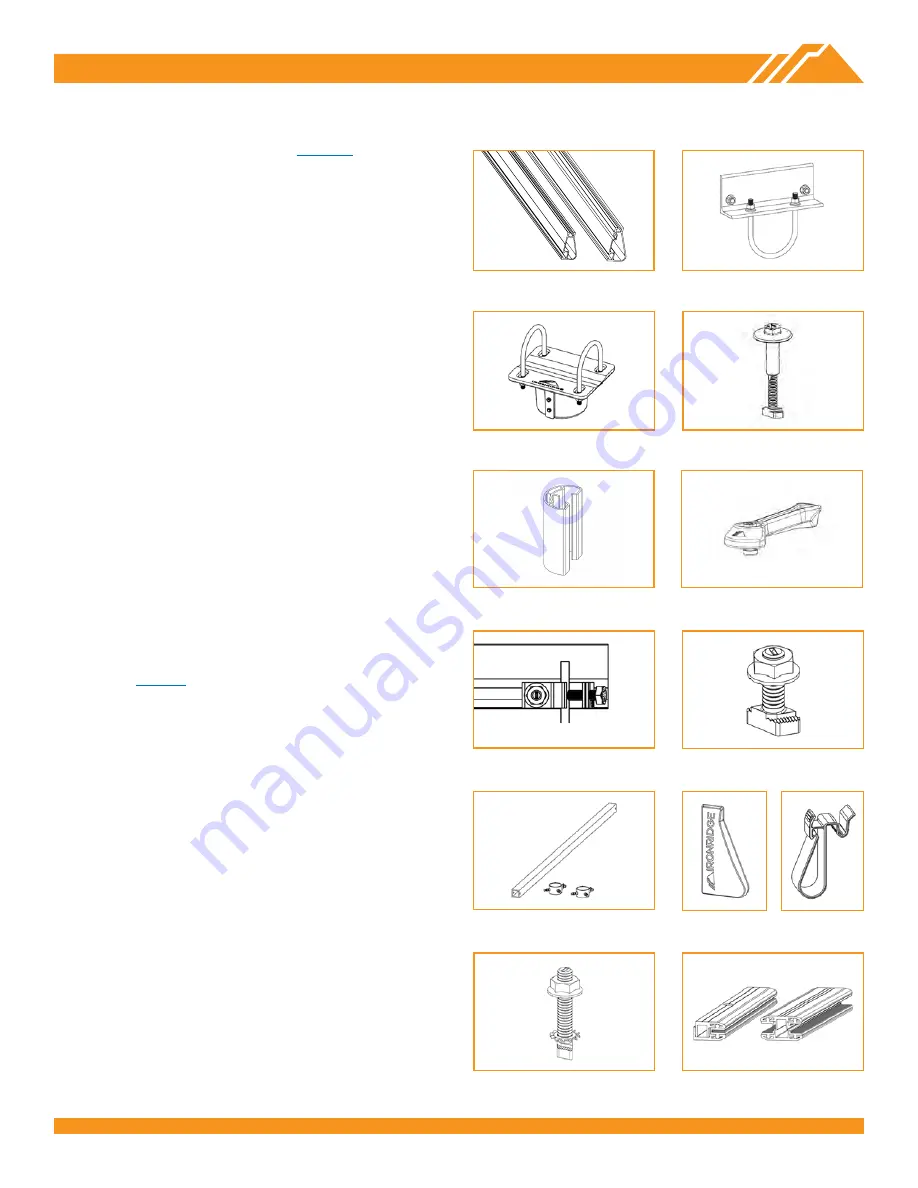

End Cap

Wire Clip