GROUND MOUNT INSTALLATION MANUAL - 6

© 2019 IRONRIDGE, INC. VERSION 2.8

3. PLACe RAILS

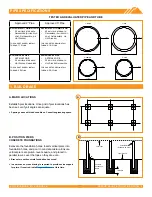

A. ATTACH HARDWARe

On the ground, attach Rail Connector brackets to rail by

sliding 3/8”-16 bonding bolts into side slot. Space out to

match pier spacing. With brackets in place, finger tighten

flange nuts onto bolts.

➢

Tape ends of rail, to keep bolts from sliding out while moving.

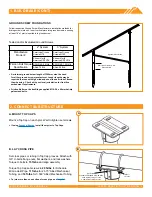

B. FASTeN CONNeCTORS

Center rails on cross pipes, leaving equal distance on

ends. Secure with Rail Connector hardware: 3/8”-16

U-bolts, flange nuts, flat washers, and lock washers.

Torque U-bolt nuts to

60 in-lbs

and bracket to

21 ft-lbs

.

➢

Spacing between rails should align with module manufacturer

recommended clamping locations.

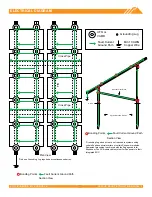

GROUNDING LUGS

Insert T-bolt in top rail slot and torque hex nut to

80 in-

lbs

. Install a minimum 10 AWG solid copper or stranded

grounding wire. Torque terminal screw to

20 in-lbs

.

➢

Only one Grounding Lug required per continuous subarray,

regardless of subarray size (Unless frameless modules are used,

see Page 10).

➢

If using enphase microinverters or Sunpower AC modules,

Grounding Lugs may not be needed. See

for more info.

➢

Grounding Lugs can be installed anywhere along the rail and in

either orientation shown.

➢

Grounding Lugs are intended to for use with one solid or

stranded copper wire, conductor size 10-4AWG.

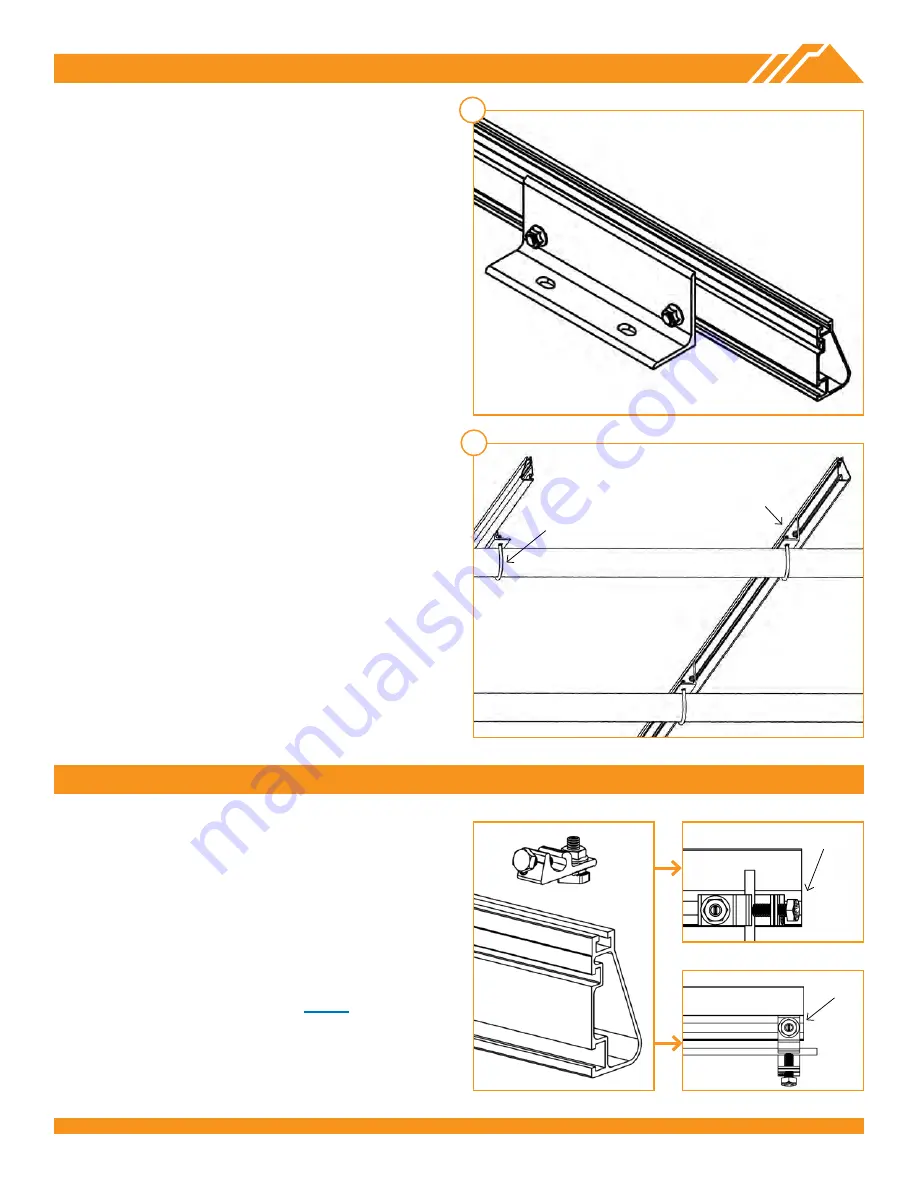

4. SeCURe LUGS

A

B

U-Bolt

60 in-lbs

Bracket

21 ft-lbs

Hex Nut

(84 in-lbs)

Terminal Screw

(20 in-lbs)

Hex Nut

(80 in-lbs)