Page 5

|

| (800) 227-9523

2013 v1.13

Rails with Integrated Grounding

Installation Manual

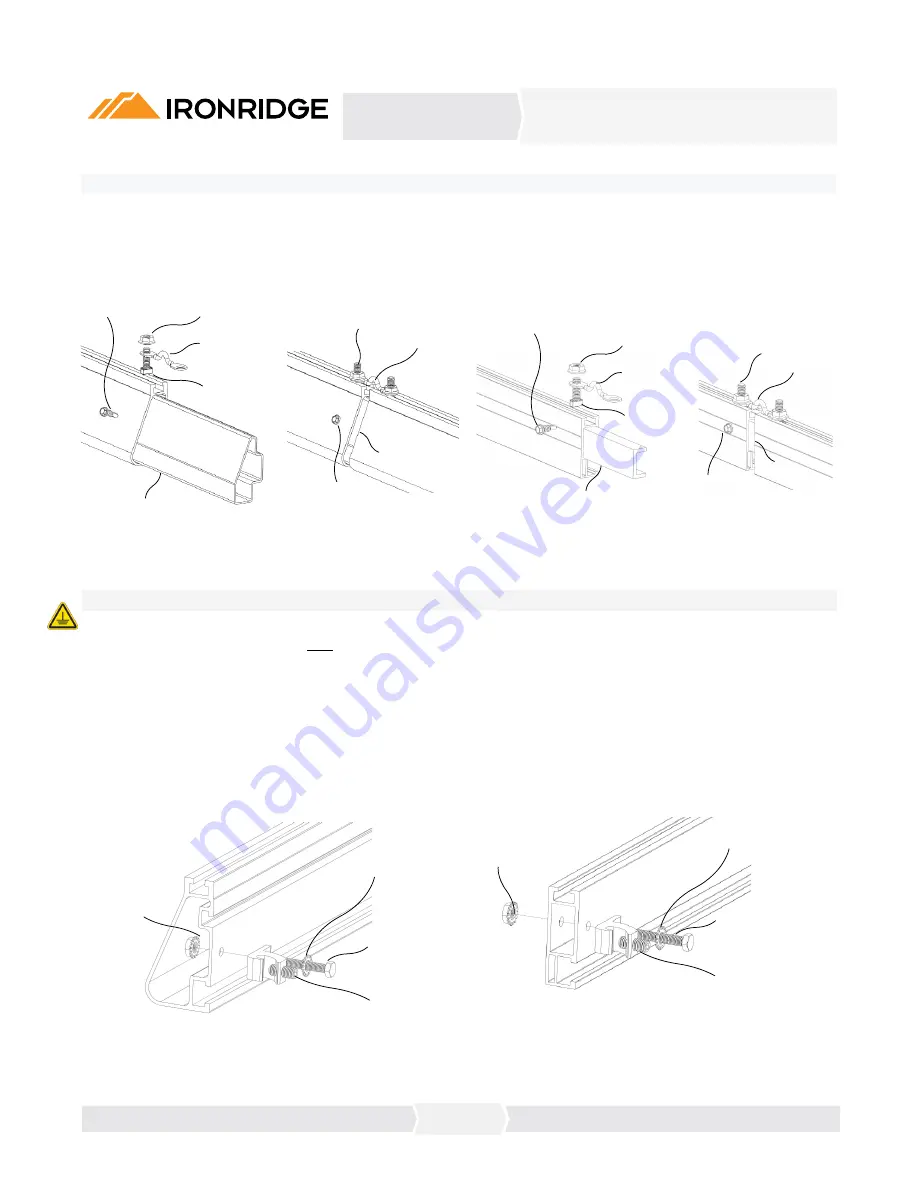

Rail to Rail Expansion Joint

A. Insert splice into first rail then secure splice with self-drilling screw.

B. Attach hardware and Grounding Strap (9AWG) one (1) inch from end of rail as shown below.

C. Next, slide the second rail over the splice and attach other end of Grounding Strap with hardware. (Use Grounding Strap only on

rails with lugs.)

Standard Rail

Light Rail

1/2” Gap

6” inside Rail

Self-drilling screw

Grounding

Strap

1” From Edge (2x)

Torque to 84 in-lbs

Centered 1” From Edge

Torque to 84 in-lbs

1/4” Hex Nut

Grounding Strap

1/4” T-Bolt

1/2” Gap

3” inside Rail

Self-drilling screw

Grounding

Strap

1” From Edge (2x)

Torque to 84 in-lbs

Centered 1” From Edge

Torque to 84 in-lbs

1/4” Hex Nut

Grounding Strap

1/4” T-Bolt

Step 4. Equipment Grounding

Note:

In order to properly ground the PV modules and IronRidge components to the equipment ground, a grounding lug or Lay-in Lug must

be attached to one (1) rail near the end of each row. This connection requires the use of one of the two following lugs.

IronRidge Grounding Lug

1. Using a 13/64” or #7 drill bit, drill a hole through one side of the Standard Rail (both sides for Light Rail), a minimum of ½” from

the end of the rail; roughly centered on internal cavity of rail as shown below. (Debur as needed)

2. Next assemble the Grounding Lug with the provided #10-32 Machine Screw, #10 Star Washer and #10 Kep Nut.

3. Install a minimum 10AWG solid copper grounding conducting wire. Torque to 20 in-lbs for 10AWG, 25 in-lbs for 8AWG, or 35 in-

lbs for 4 and 6AWG.

Standard Rail

Light Rail

#10 Kep Nut

Star Washer

#10 Hex Bolt

Torque to 32 in-lbs

#10 Set Screw Torque

to 20 in-lbs for 10AWG

Star Washer

#10 Hex Bolt

Torque to 32 in-lbs

#10 Set Screw Torque

to 20 in-lbs for 10AWG

#10 Kep Nut