www.ironridge.com | 800-227-9523

© Copyright 2012 IronRidge, Inc. All rights reserved.

8

| Standard Rail Installation Manual

Parts required for this step

Qty

Part Number

Internal Splice

1

29-7000-010

110-16 x1/2” , self-drilling, self tapping screw, SS

8

48-1016-500

WEEB Bond Jumper (if used)

see below 29-4000-003

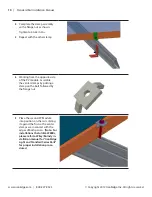

1.

On the next piece of rail, slide 3/8-16”

bolts into the side facing t-slot on the

rail. Space the bolts out to match the foot

spacing.

2.

On this same piece of rail, slide 1/4-20”

bolts into the top facing t-slot on the rail.

Space the bolts out to match the panel

spacing.

3.

Lay the rail on its side, with the slotted

side down as shown.

4.

Slide the internal splice half way into the

internal cavity in the rail. It should extend

approximately six (6) inches into the cav-

ity.

5.

Using two of the self-drilling, self-tapping

screws, secure the internal splice into the

rail utilizing the screw pattern shown at

right.

(Note- For installations that utilize

WEEB Bonding Jumpers, please refer to

Wiley/Burndy installation manual for

“IronRidge Light and Standard Series

Rails” for proper installation proce-

dures.)

6.

Loosely mount this piece of rail onto its

footings.

7.

By moving this second rail along its foot-

ings, the internal splice should slip into

the cavity on the first rail, with the rails

butting tightly and evenly together.