Congratulations. You have just purchased an IRONSIDE GARDEN 7. This product has been designed to meet your requirements. Read this

leaflet carefully in order to use the tool correctly and safely.

TECHNICAL DATA

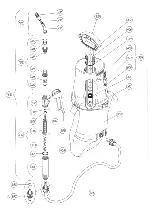

A sprayer made of top quality materials not subject to attack by treatment products, including copper derivatives. Adjustable nozzle. Adaptor for accessories.

Directional fiber lance. Ergonomic handle. Filter on lance. Transparent hose with nuts, without clamps. Original rubber seal. Viton pressure chamber closing

valve. Strong polypropylene tank with contents indicator and instructions for use. Lance fastener. Transparent plastic tube fastener to check the level of liquid

through the hose, with the tank and handle open to avoid pressure differences. Accessory fastener. External safety valve. Shoulder strap.

GUARANTEE

Our goods are guaranteed for three years against any manufacturing or material defect, counting from the date on which they are purchased by

the user.

This guarantee is limited strictly to the replacement free of charge of parts recognized as faulty by our departments. The guarantee does not apply in

case of improper use of our materials, disassembly and/or alterations to our units or maintenance required by parts subject to normal wear and tear.

The guarantee does not apply in case of negligence, imprudence or irrational use of the material.

Transport costs of parts under guarantee, as well as labour not carried out at our works, is payable by the user.

To make use of the guarantee, the part for which the claim is made should be sent to us free of transport costs, together with the guarantee voucher

to be found in the packaging, properly completed.

RECOMMENDATIONS FOR USE

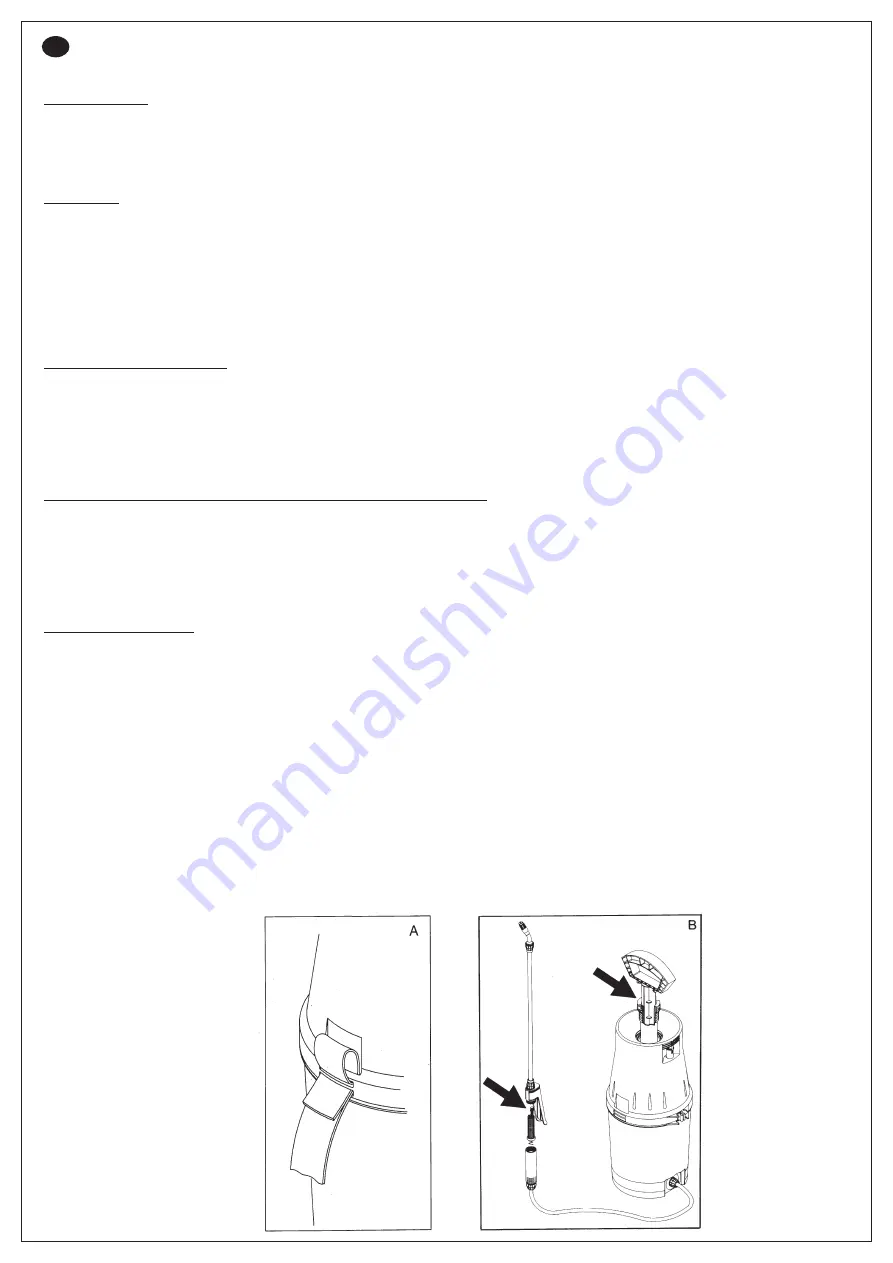

1) Fit the strap to the sprayer as shown in drawing A.

2) The hose (725) is to be attached to the lance (753) and the bottom of the tank.

3) Fill the tank to the maximum level (5 litres) and screw the complete chamber (921) tightly to the tank.

4) Pressurize the unit by pumping 18 times with the handle (407). If maximum pressure is exceeded, valve (404) is actuated, releasing the air.

To work, press the handle and adjust the nozzle to obtain the desired spray. Pressure and therefore spray intensity drop with use. Pump more

to regain pressure.

MAINTENANCE-MOST FREQUENT MALFUNCTIONS AND THEIR SOLUTIONS

1) Clean the sprayer and the circuits of liquid, including the filters, after each working day. This can be done by working the device with clean water,

adding a little household detergent if desired.

2) Avoid seals becoming dry by washing the equipment after work and applying a few drops of oil at the points shown in drawing B.

3) Nozzle (135) obstructed. Clean with water jet or non metallic instruments.

4) If the filter becomes blocked, remove the handle (166) for cleaning.

5) To replace the seal (164), remove the clip on the top of the chamber (406) and pull out the handle (407).

SECURITY REGULATIONS

1) Do not use chemical products out of the indicated application field

2) Always respect the instructions and dosage, on the packaging labels, that the manufacturer recommends for the treatment product that you

will be using.

3) Do not eat, drink or smoke during the preparation and the treatment.

4) Do not use the spray on persons, animals, or electric installations.

5) Do not use the treatment when there is strong wind or extreme heat.

6) In case of intoxication, consult your doctor and provide him/her with the package of the treatment product.

7) Do not dump product or cleaning residues near courses of water, wells, etc. that are going to be used for human or animal consumption.

8) Use proper protection equipment, masks, glasses, gloves, shoes, etc.

9) Do not modify the sprayer, nor block the safety valve. Do not connect it to an external pressure source (manual use only). Do not use the

device if it is damaged, deformed or if its original shape has been altered.

10) Store the sprayer indoors protected from frost and fierce heat (between 5º and 30º C).

EN

Summary of Contents for IGS7

Page 2: ......