Kwik-Way

SVS II Deluxe Valve Refacer

Copyright © 2018 by Irontite Products Inc.

All Rights Reserved. Rev. 180802

pg. 11

SETTING SPINDLE SLIDE STOPS

This machine is equipped with adjustable stops to limit the travel of the grinding wheel spindle slide.

These stops, when set, prevent the wheel from striking the chuck or the valve stem.

1. With the valve installed in the chuck, all motors off, and the thumbscrews loose, advance the

traverse handle to the left.

2. Feed valve up to valve wheel.

3. Be sure the grinding wheel does not strike either the chuck or the valve stem.

4. Slide the right hand adjustable stop up against the fixed stop and tighten thumb screw.

CONTROLS AND SWITCHES

Before attempting to operate this machine, first familiarize yourself with all controls and switches and

the functions of each.

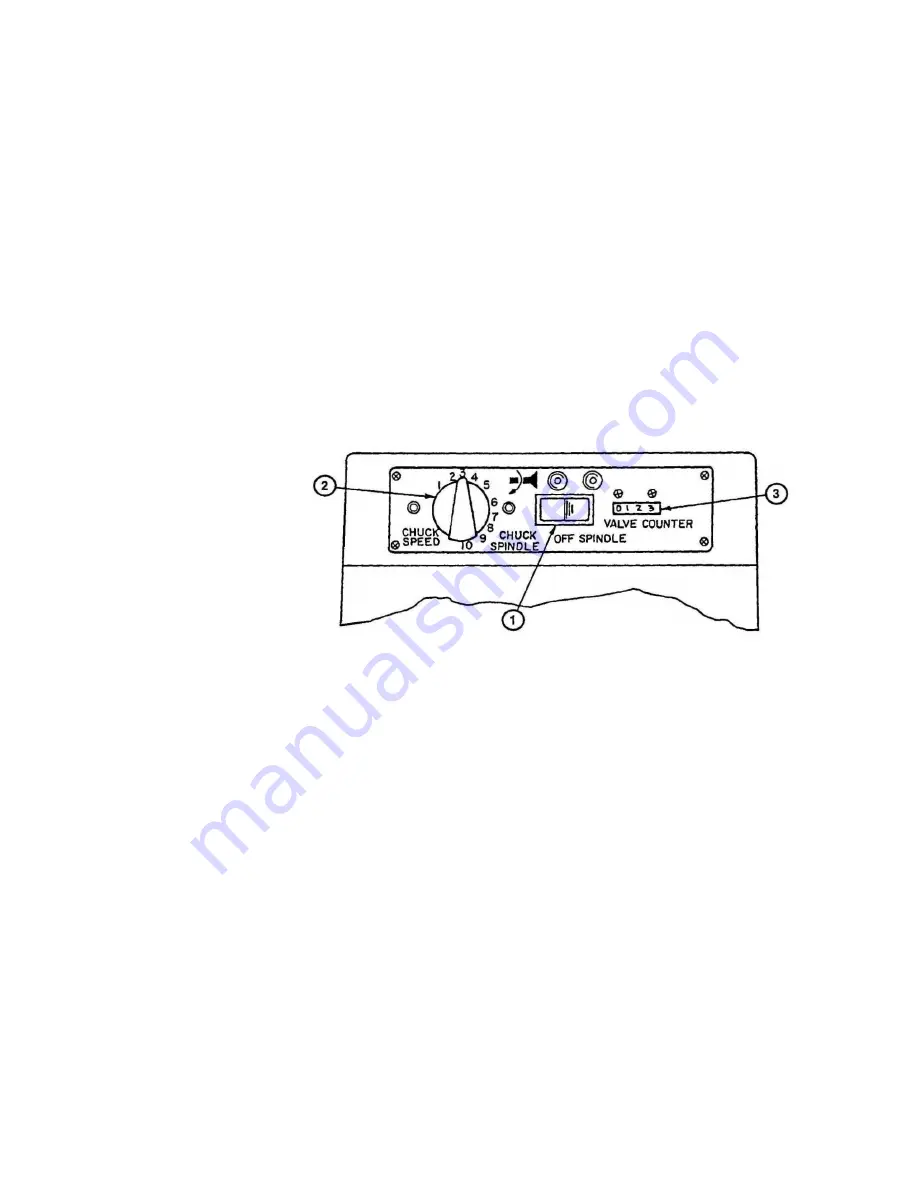

MAIN SWITCH (Item 1, Figure 2 below)

This switch has three positions. In the left position, both the spindle and the chuck motor are on. With

the switch in the right position, only the spindle motor will run. When centered, both chuck and spindle

motors are off.

CHUCK SPEED CONTOLLERS (Item 2, Figure 2 above)

Your SVSII Deluxe Valve Facer is equipped with a variable speed chuck motor, which allows you to

alter the rotational speed based on the valve head diameter (See chart on chuck cover).

SPINDLE SLIDE SWITCH

This machine is equipped with an automatic switch, which shuts off the spindle (grinding) motor, chuck

motor and the coolant pump when the traverse handle (Item 3, Figure 4) is in the far right position.

VALVE COUNTER (Item 3, Figure 2)

This machine is equipped with an automatic valve counter enabling you to keep an accurate count of

valve facing production.

Figure 2