Page of 21

20

For replacement parts and/or technical questions, please call

1-800-222-5381

.

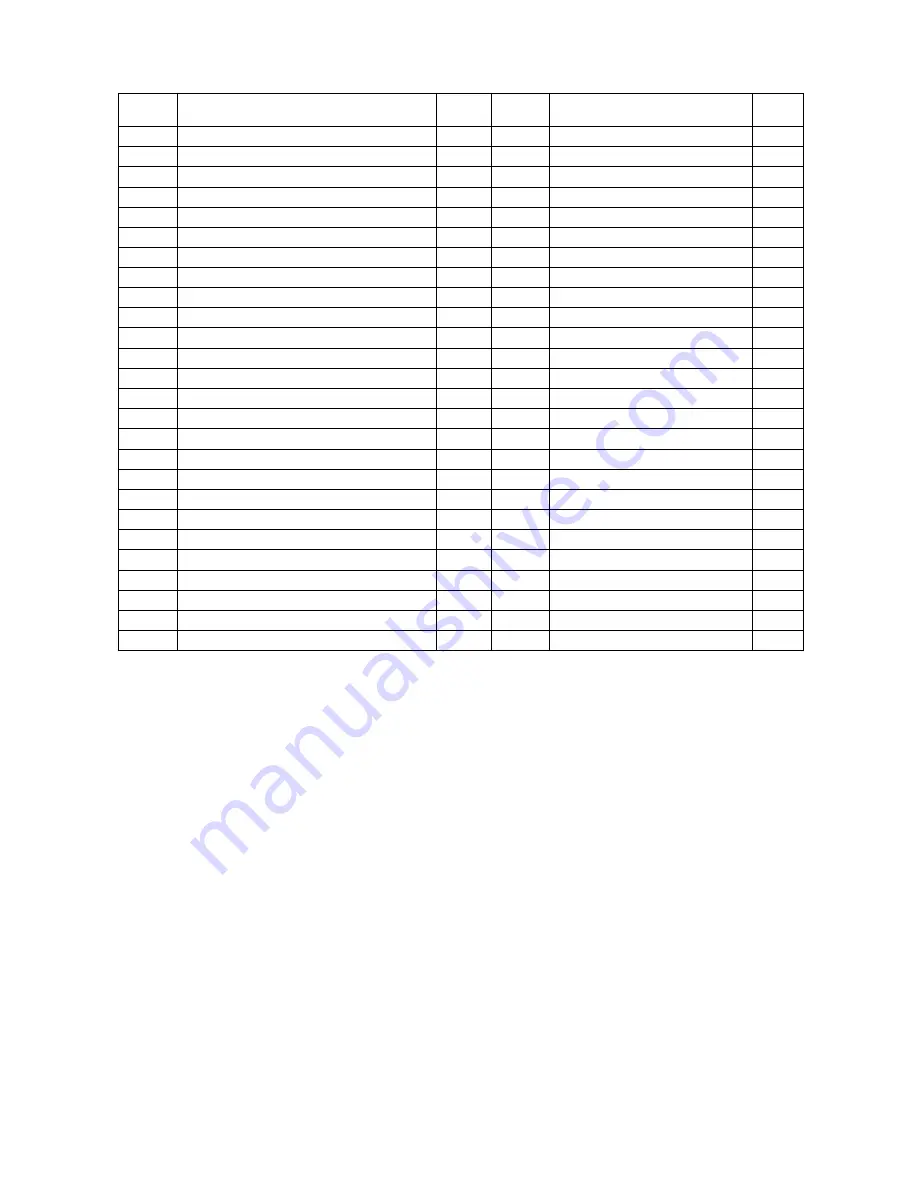

NO.

Part Name

QT

NO.

Part Name

QT

1

Jig (60)

1

27

Honing Wheel

1

2

Knurled Screw

2

28

Motor Shaft

1

3

Washer (#6)

1

29

Split Pin (4x22)

1

4

Spring

1

30

Split Pin (4x45)

1

5

Tension Plate

1

31

Washer

1

6

Holder

1

32

Body

1

7

Set Collar

1

33

Self Tapping Screw

4

8

Wing Screw (M6x16)

1

34

Power Switch

1

9

Hand Grip

1

35

Power Cord

1

10

Jig(70)

1

36

Changeover Housing

1

11

Clamp (#12)

2

37

Capacitor

1

12

Spring

2

38

Motor

1

13

Pressure Plate

1

39

Rubber Foot

4

14

Washer (#6, 4)

2

40

Self Tapping Screw

4

15

Knob

2

41

Water Tank

1

16

Support Plate

1

42

Angle Guide

1

17

Nut (M12)

1

43

Abrasion Paste Jar

1

18

Washer (#12)

2

44

Pin Nut (M6)

4

19

Grinding Stone

1

45

Motor Mounting Plate

1

20

Collar Bushing

2

46

Pin

1

21

Knob

4

47

Washer

2

22

Set Collar

4

48

Spring

1

23

Tool Support

1

49

Lock Washer (RS8)

2

24

Friction Gear

1

50

Washer

4

25

Washer (#8)

1

51

Hex Screw

4

26

Nut (M8)

1

52

shaft sleeve

1