Page 11 of 18

6.

To pull out the wire rope, disengage the clutch control by loosening two lock nuts and turning the

clutch knob (19) counterclockwise, to loosen it. Slide the loop of the hook strap over the hook and

then pull on the hook strap to pull out the wire rope.

⚠

WARNING

Leave at least five full turns of wire rope on the drum.

7.

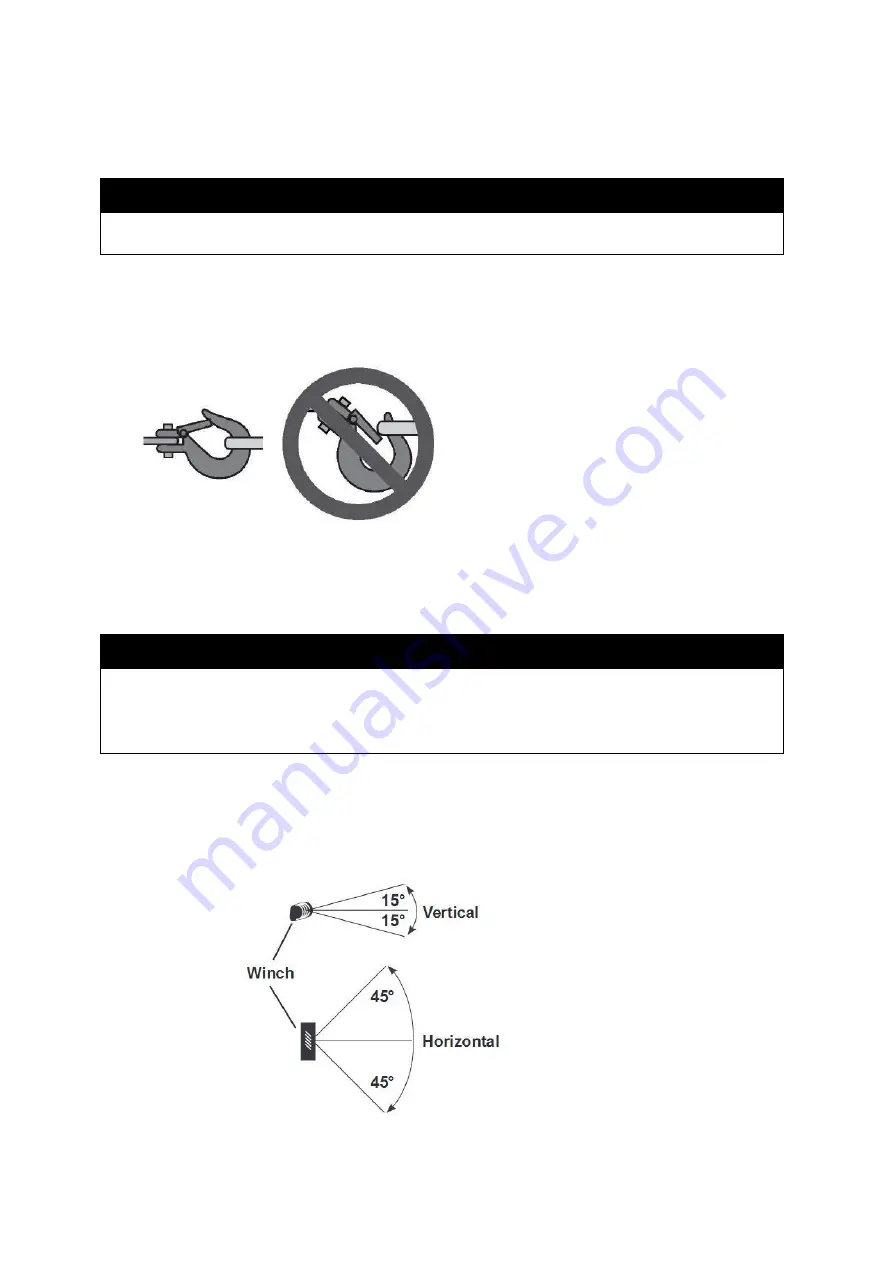

Hook onto the object using a pulling point.

Do not wrap the wire rope around the object and hook

onto the wire rope itself. This can damage the object being pulled, and kink or fray the wire rope.

8.

The attachment point must be centered in the loop of the hook and the hook

’s safety clasp must

be fully closed. See the illustration below.

9.

Do not use a recovery strap while winching. They are designed to stretch and can suddenly whip

back towards the operator during a winching operation.

10. Place a heavy rag or carpet (not included) over the wire rope span, 6 feet from the hook, to help

absorb the force released if the wire rope breaks.

11. Re-engage the clutch by turning the clutch knob (19) clockwise until tight. Do not force it or

overtighten.

⚠

WARNING

Do not allow anyone to stand near the wire rope or in line with the wire rope behind the winch while

it is under power. If the wire rope should slip or break, it can suddenly whip back towards the winch,

causing a hazard for anyone in the area. Stand to the side while winching.

12. Operate the controls briefly to ensure they work properly.

13. When it is safe to do so, use the power switch on the pendant controller to retract the wire rope,

and winch the item as desired. Do not power the hook all the way into the fairlead to prevent

damage.

14. Do not operate the winch at extreme angles. Do not exceed the angles, shown in the illustration

on the following page, for a roller fairlead.

Summary of Contents for 54127

Page 14: ...Page 14 of 18 Parts Diagram...