Ironwood BR23 | User Manual

11

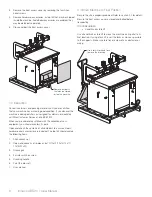

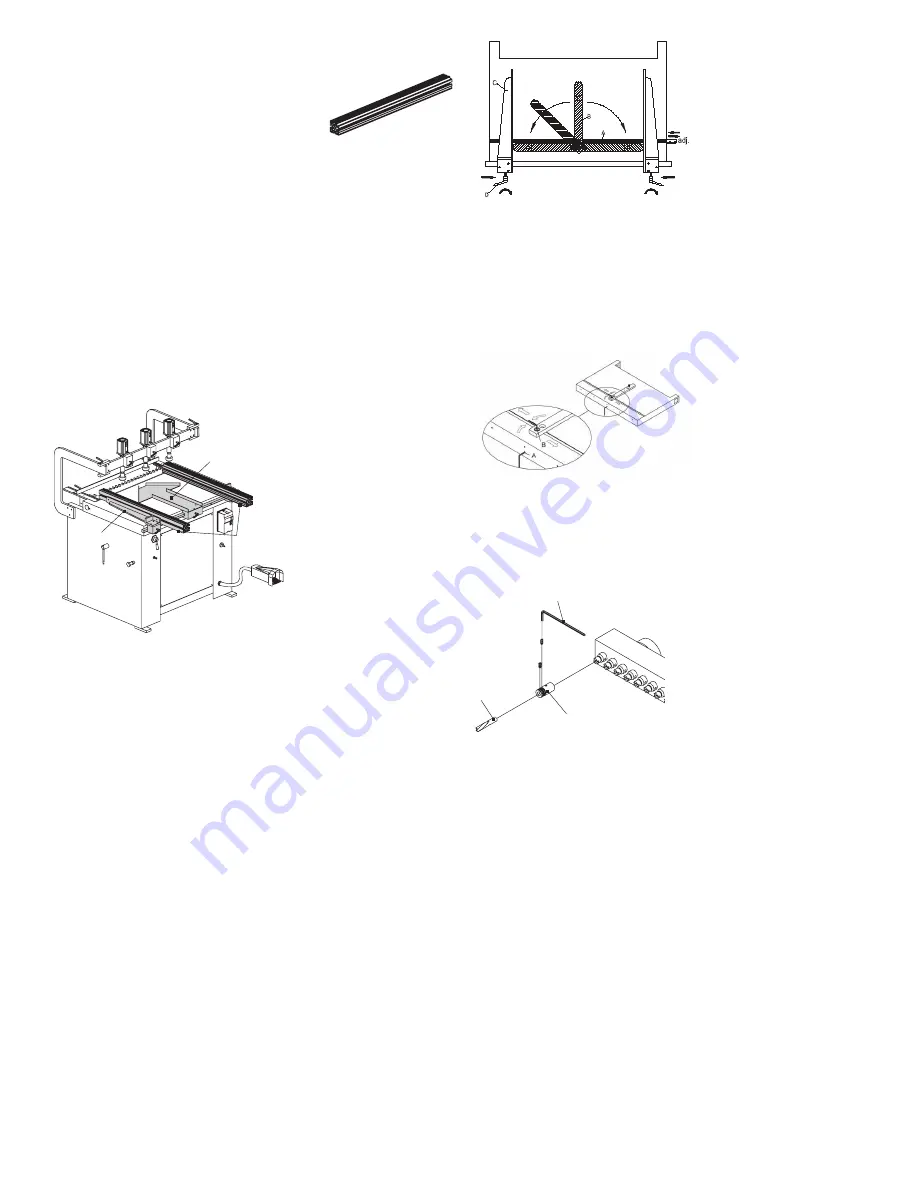

4.2 Left- and Right-Side Fences

PARTS REQUIRED:

• 2 side fence sections

• 2 side fence housings (1 left, 1 right)

Right- and left-side fences are easily added or removed to

accommodate various applications.

To assemble:

1. Slide the side fence housing onto steel guide rail mounted on

the front of the machine table.

2. Slide the side fence onto alignment blocks on the side fence

housing.

3. Lock the side fence to secure it to the fence housing.

4. Move the side fence to desired position.

5. Lock in place.

Repeat steps for the opposite side fence.

45° Fence assembly

Left and

right side

fences

Side fence housing

4.3 45º fence

PARTS REQUIRED:

• 1 45º fence assembly

The 45º fence assembly is easily added or removed to

accommodate 45º parts.

To assemble:

1. Remove the side fences.

2. Slide the 45º fence into position.

3. Lock the 45º fence in place.

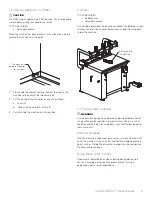

4.4 The Mirror-Image Device

1. Calibrate the zero point of rule (A) to the middle of the mirror-

image device (B).

2. Turn the device (B) left/right side to adjust the length user

needs. (Either left or right side first is ok.)

3. Move the Fene LH (C) to touch the top of device (B) to get the

correct distance.

4. Lock the lever (D) to fix the correct distance.

5. Repeat steps 3-4 to adjust the length of another side.

Zero-point adjustment - The zero-point has been set by factory

before shipment. Please do not adjust the zero-point (screw A), if not

necessary.

Loosen the screw (A) with 1-2 turns. Loosen the screw (B) with 1-2

turns and adjust mirror-imaging advice to zero-point. Tighten screws

(A) and (B) when the desired zero-point is obtained.

4.5 Drill Bits

PARTS

REQUIRED: TOOLS

REQUIRED:

• Drill bit quick chucks (supplied) • Hex Allen wrench

• Drill bits (not supplied)

1. Determine which drill bit locations will be used to accommodate

the application.

NOTE: Each spindle is colored red or black based on rotation

direction (left or right). Please observe the rotation direction when

selecting tooling for each spindle.

2. Carefully insert a drill bit quick chuck into the spindle in the

desired positions. Make sure the pin inside the quick chuck is

engaged with the notch on the spindle.

3. Install drill bits into the other quick chucks in the same manner.

4. Tighten the two set screws with an Allen wrench.

5. Make sure the bits are aligned and all at the same height.

Remove and reinstall any out-of-alignment drill bits so that all

are aligned.

Remove Drill Bits

To remove a drill bit quick chuck (with drill bit) from the spindle,

slightly turn the quick chuck to the left and pull up.

Hex Allen wrench

Drill bit

Drill bit quick chuck