Ironwood BR23 | User Manual

12

5.0 Connect to Power and Air

5.1 Power Connection

• Voltage – Steady state v/- 10% of nominal voltage.

• Machine needs steady voltage at all times.

WaRninG

Before connecting power to the machine, make sure all screws and

fasteners are tightened and all mechanical functions work freely.

WaRninG

A licensed electrician must complete all connections to electrical

power.

Before connecting to a power source, confirm that the electrical

current of the power source is the same as the electrical system

supplied with your machine. Ensure the machine is protected with

an external over current protective device per your local regulating

authorities.

Machine must be properly grounded to prevent electric shock.

Never connect the yellow/green wire to a live terminal.

Once connected to power source, terminals are electrified even

while the power switch is off.

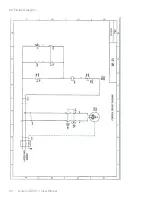

L2

2

3

L1

PE

PE

L1

1

L2

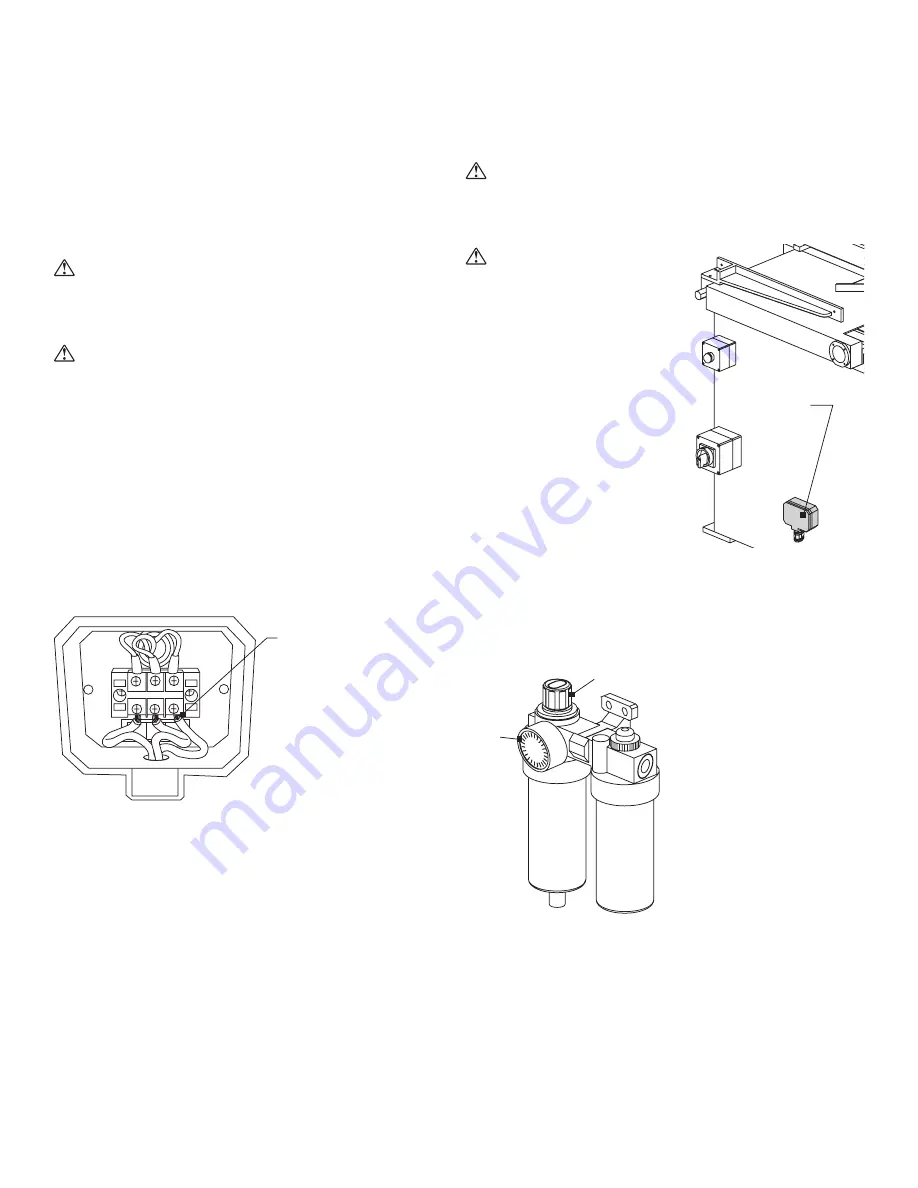

Proper wiring inside

the terminal strip box

To connect source power to the machine:

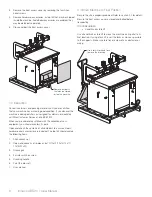

1. Remove two screws and remove terminal box cover.

2. Remove clear plastic insulator that covers the terminals.

3. Insert source power cables through opening of terminal box.

4. Connect the two power cables to terminals L1 and L2, and the

yellow/green ground wire to ground terminal.

5. Replace the clear plastic insulator and the power box cover.

WaRninG

Always shut off power at source before removing terminal box cover.

Failure to comply with this action may result in electric shock.

Caution

We have covered some basic

electrical requirements for the safe

installation of your machine. These

requirements may not cover all

installation requirements. You must

confirm that your particular electrical

configuration complies with all

local codes. Ensure compliance by

checking with your local municipality

and a licensed electrician.

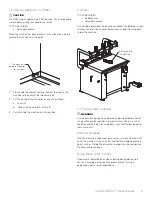

5.2 Air Supply Connection

Boring carriage adjustment and

Quick-Release clamp operation are

pneumatically controlled using the

foot pedal.

A ¼" N.P.T. inlet is supplied with the machine’s air fitter/regulator to

connect the machine to the air supply.

The air pressure regulator should be set to 90-100 psi.

Pressure

guage

Regulating knob

To adjust the pressure:

1. Pull up on the outer ring of the regulating knob.

2. Turn the regulating knob counterclockwise to let air exhaust to a

pressure level below the desired setting.

3. Turn the knob clockwise to slowly increase the pressure to the

desired setting.

Remove

terminal

box cover