Ironwood BR23 | User Manual

14

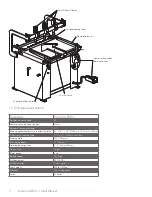

7.0 Operation and Adjustments

7.1 Controls

A

B

D

E

C

The controls on the front of the machine provide the following

functions:

A. Start: Push to start drill rotation.

B. Stop: Push to stop drill rotation.

C. Mode Selector Switch

• Position 1 (hand symbol): Manual mode. The boring head

carriage will move pneumatically into the desired position

without spindle rotation. This position can be used to raise

and lower boring head to easily change tooling.

• Position 2 (circular arrows): Automatic mode. The foot pedal

activates the pneumatic movement of both the boring head

carriage and the work hold-down clamp; the drill spindles

will run automatically when the boring head carriage moves

up/forward and stop when it is in a lowered/back position.

D. Handle Lever Valve: Adjusts the angle of the boring head

carriage between 90 and 0 degrees.

E. Feed Rate Control Knob: Sets speed at which boring head drills

into workpiece

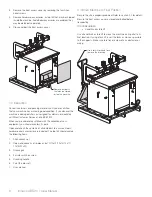

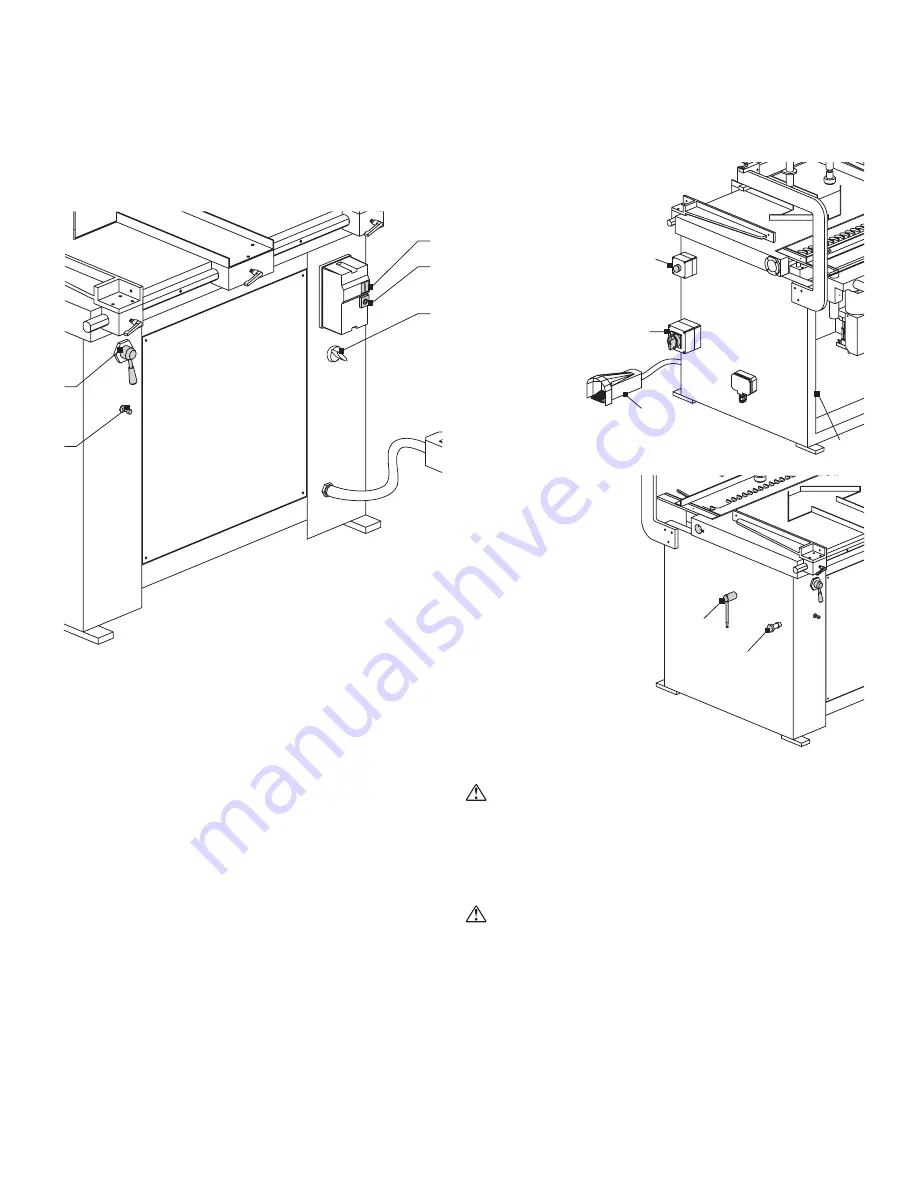

Right side of the machine:

A. Emergency Stop

B. Air Supply Connection:

Compressed air

connection point.

C. Main On/Off Switch:

Turns main power

on and off.

D. Foot Pedal

Control: Starts

the drilling

cycle when

depressed.

Left side of the machine:

A. Lock mechanism:

Locks the tilt carriage

in place so it cannot be

moved when operating.

B. 45º stop: Enables quick

tilt setup at 45º.

Foot Pedal

The foot pedal activates the

pneumatic movement of

both the workpiece hold-

down clamps and the boring

head carriage.

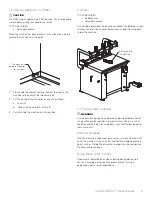

7.2 Operation

WaRninG

Always keep the boring head carriage in the LOCK position, except

when making an adjustment.

Step 1:

Activate air supply to machine

WaRninG

When air pressure is first applied to the machine, the boring head

carriage may move. Do not stand behind the machine.

NOTE: The air supply must be on to make certain adjustments and

enable movement of the workpiece hold-down clamps and boring

carriage.

Step 2:

Turn on power to machine

Step 3:

Ensure air pressure is correct

Step 4:

Set boring depth using the revolving turret with stops

A

C

B

D

A

B