Ironwood BR23 | User Manual

16

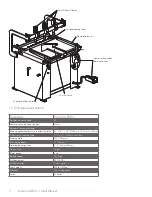

Step 7:

Position the workpiece hold-down clamps

Hold-down

clamp

Hold-down

assembly

Assembly

lock lever

Hold-down

lock lever

Position the hold-down clamps according to the dimensions of your

workpiece to securely hold it in place while boring.

To accommodate workpiece thickness:

1. Place the workpiece on the table under the hold-down clamps.

2. Lower the hold-down clamps to within an inch of the surface of

the workpiece.

3. Lock the hold-down clamps in place.

To accommodate workpiece width:

1. Loosen the lock lever for each hold-down to be adjusted.

2. Move the hold-down(s) right or left to the optimal position to

secure your workpiece.

3. Tighten the lock levers.

NOTE: A minimum of two workpiece hold-down clamps should

always be used when possible.

To reposition the hold-down assembly:

1. Loosen the lock levers at each end of the assembly.

2. Move the assembly forward or back as needed.

3. Tighten the lock levers.

Adj Valve for Hold-Down: Normal pressure 3.5-4 kgs/cm2 is to

reduce exhaust through the pressure plate and avoid O-ring cracked

and licking the pressure. But if user takes hard drilling*, then the

work piece would be removed easily. In this situation, please

adjust the pressure to 5-6 kgs/cm2 to make machine have enough

pressure to clamp the work piece.

*Hard drilling: Hard material work piece, thick work piece, drilling

many holes at a time, etc.

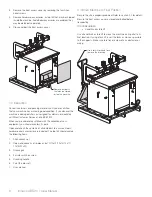

Step 8:

Position flip stops

Position the four flip stops on the fence according to the dimensions

of your workpiece and the desired boring points. The stops can

be moved to any point along the fence. The fence has an integral

measuring guide with magnifying lens for precision set-up.

1. Loosen the flip stop locking levers.

2. Slide the flip stops to the desired positions on the fence.

3. Tighten the locking levers.

Step 9:

Position side profile fences

Right- and left-side profile fences are easily added or removed to

accommodate various applications where referencing from the side

is necessary.

Step 10:

Position rear fence

Position the rear fence in proper relation to the drill block for your

application.

1. Loosen the locking handles on the rear fence.

2. Move the fence forward or back as needed according to the

integrated scale.

3. Tighten the locking handles when rear fence is in position.

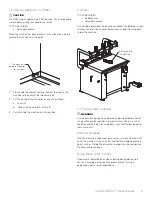

Step 11:

Set feed rate

Feed rate is determined by the type of wood and drilling operation.

In general, hard woods require a lower feed rate; soft woods require

a faster rate.

Turn the knob clockwise to reduce the feed rate for the boring head

carriage. Turn counterclockwise to increase the feed rate.

NOTE: If there is burning on a drill hole or chip out on a through-

hole, feed rate is too fast or too slow. Adjust as needed based on

the material being machined.

Step 12:

Select operation mode

Position 1 (hand symbol): Used when setting up the machine for

drilling depth and position. The foot pedal activates the pneumatic

movement of the boring head carriage into the desired position

without spindle rotation.

Position 2 (circular arrows): Used for normal machine operation. The

foot pedal activates the pneumatic movement of both the workpiece

hold-down clamp and the boring head carriage; the drill spindles will

run automatically when the boring head carriage moves up/forward

and stops when it is in a lowered/back position.