Ironwood BR23 | User Manual

19

8.0 Maintenance

WaRninG

Before performing any type of maintenance or adjustments, make

certain that the machine is disconnected from its power and air

source and completely shut off.

WaRninG

Never operate the machine until it has been properly lubricated and

all necessary maintenance work has been completed.

NOTE: After changing a setting, making an adjustment, performing

repair/maintenance work, or troubleshooting, please check that all

applicable safety functions are working properly before performing

another operation.

Clean all machinery parts and surrounding areas every day.

Keep a maintenance record and perform recommended

maintenance checks.

8.1 Lubrication

Weekly, clean and lightly oil the drill head guide bars and the

positioning screw of the boring head carriage using an ISO VG32 oil.

Every 1,000 hours of machine operation, lubricate the boring

head using a grease gun and a non-melting moly grease. Apply no

more than 6 grease-gun strokes.

Spindle bearings are permanently lubricated and require no further

lubrication.

Spindle bearings may purge grease during the first 20 hours

of operation. Wipe away any excess grease before starting the

machine.

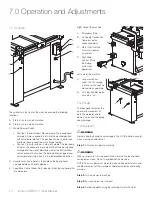

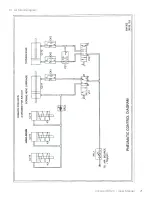

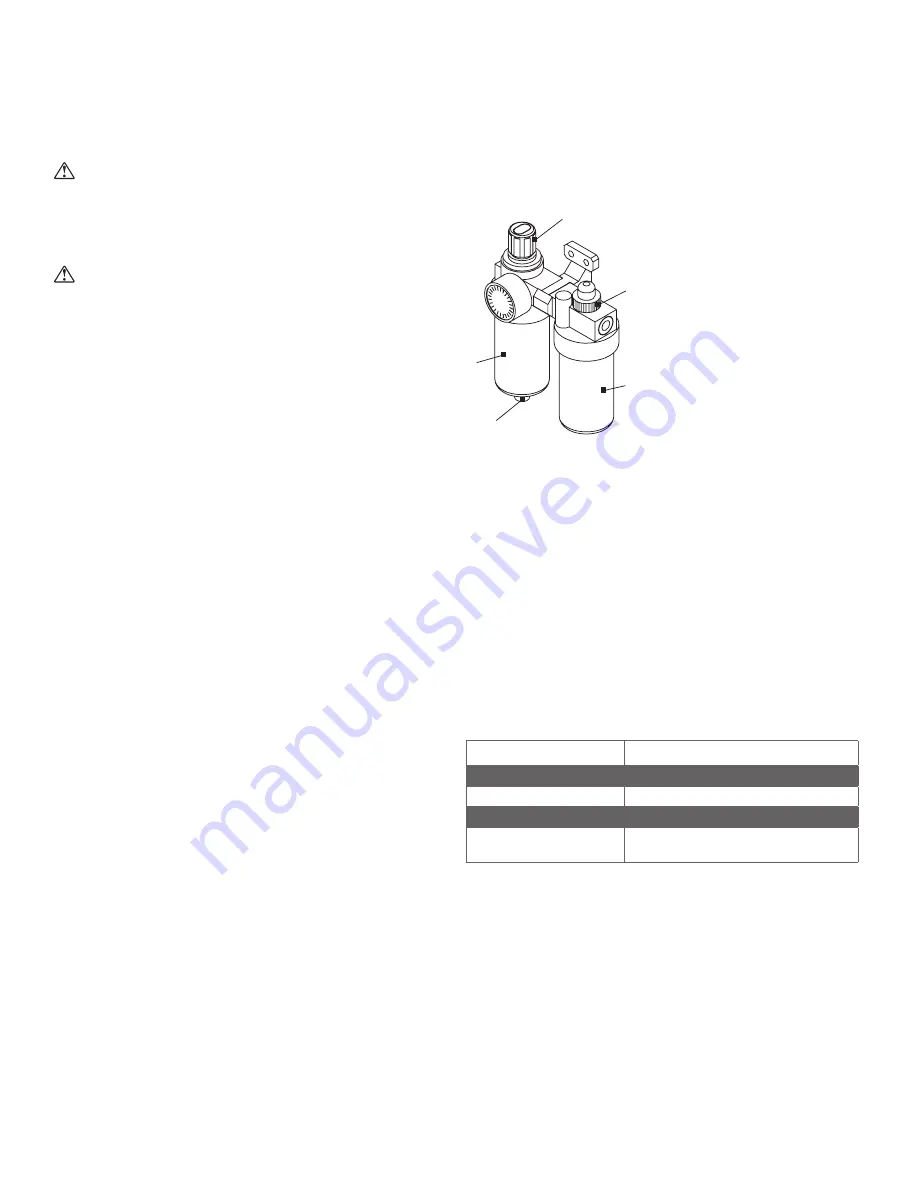

Pneumatic System

A

E

B

D

C

Periodically fill the oil reservoir (B) with pneumatic oil. Use high-

quality pneumatic oil such as VG32 or other approved lubricant.

Drain and refill oil if there is condensation inside the reservoir (C). To

drain, press the drain knob (D).

NOTE: Reduced air flow can cause lack of lubrication. Be sure air

flow is properly adjusted to avoid mechanical damage from lack of

lubrication.

8.2 Cleaning

Blow dust from the machine frequently to avoid buildup of waste

material, dust and other debris.

8.3 Inspection

Feature

Interval/Situation

Boring head and bits

Every use

Emergency stop

Everyday – by functional test

Pneumatic system

Everyday

Electrical cabinet/system

Monthly: wiring terminals loose, insulation

deterioration, vacuum dust