Ironwood BR23 | User Manual

3

1.0 General Information

1.1 Thank You!

Thank you for your purchase of the Ironwood BR23 construction

boring machine. At Stiles Machinery, our goal is to ensure that you

are fully satisfied with your purchase. This manual is provided so

that you may properly assemble, operate, and maintain your BR23.

Should you need help, our team of dedicated service personnel are

available to answer your questions and provide any resource reco

mmendations you may need.

Warranty and Support

All Ironwood machines are designed to meet the exacting standards

demanded by craftsmen like you. Ironwood machines include a

one (1) year parts warranty and two (2) years of free 24/7 technical

support beginning at date of shipment. Standard technical support

remains in effect for free for the lifetime of the machine thereafter.

Warranty service work is not covered by manufacturer’s warranty.

Stiles’ service team is available for an additional charge.

1.2 Before Contacting Stiles

Please have your machine model and serial number available when

contacting Stiles Machinery with questions. The machine’s model

and serial number are listed on the metallic plate located on the

machine’s frame.

Information regarding the electrical system and pneumatic supply

are also listed on the metallic plate.

Machine information plate

Stiles Technical Support

616.698.6615

Stiles Parts

800.PARTS.80 (800.727.8780)

Website

www.stilesmachinery.com/ironwood/br-23

Machine Model ____________________________________________

Machine Serial Number _____________________________________

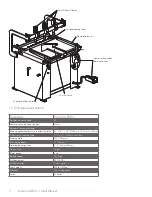

1.3 Features

• Three Quick Release pneumatic clamps firmly secure workpieces

while boring and prevent operator injury

• Clamp heads have a rubber coating to prevent workpiece

damage

• Machine controls are conveniently positioned

• Digital readouts enable precise and consistent boring-unit

positioning

• Pneumatic tilting controls and tilt-lock allow quick and accurate

boring-unit settings from 0-90º

• 23-spindle single-head boring unit

• Easily removable side-profile fences allow quick changeover from

doweling for casegoods to System 32 line boring

• 3-meter extension fence enables boring of large workpieces.

• Boring feed speed adjustment allows clean boring operations

and superior boring quality

1.4 Intended Use

The Ironwood BR23 is designed for closet, casegood, and cabinet

making. The machine is ergonomically designed for applications

that require boring a long, straight row of up to 23 holes in a single

stroke. Drill bits rise from beneath the workpiece for fast, clean, safe,

boring.

The BR23 allows System 32 line boring, with hole spacing of 32mm

to facilitate the easy installation of dowels, brackets, hinges, cam

fittings, shelf support, connecting screws, etc. The boring head

carriage can be adjusted to a 90°, 45°, or 0-degree position. Holes

can be bored in the faces or edges of the workpiece.

This robust boring machine allows quick set-up times, digital

read-outs for improved accuracy, and a conveniently large working

surface for applications.