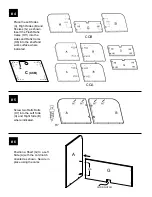

Place the Worksurface (C) face

down on a clean, carpeted surface

with the pre-drilled holes facing up.

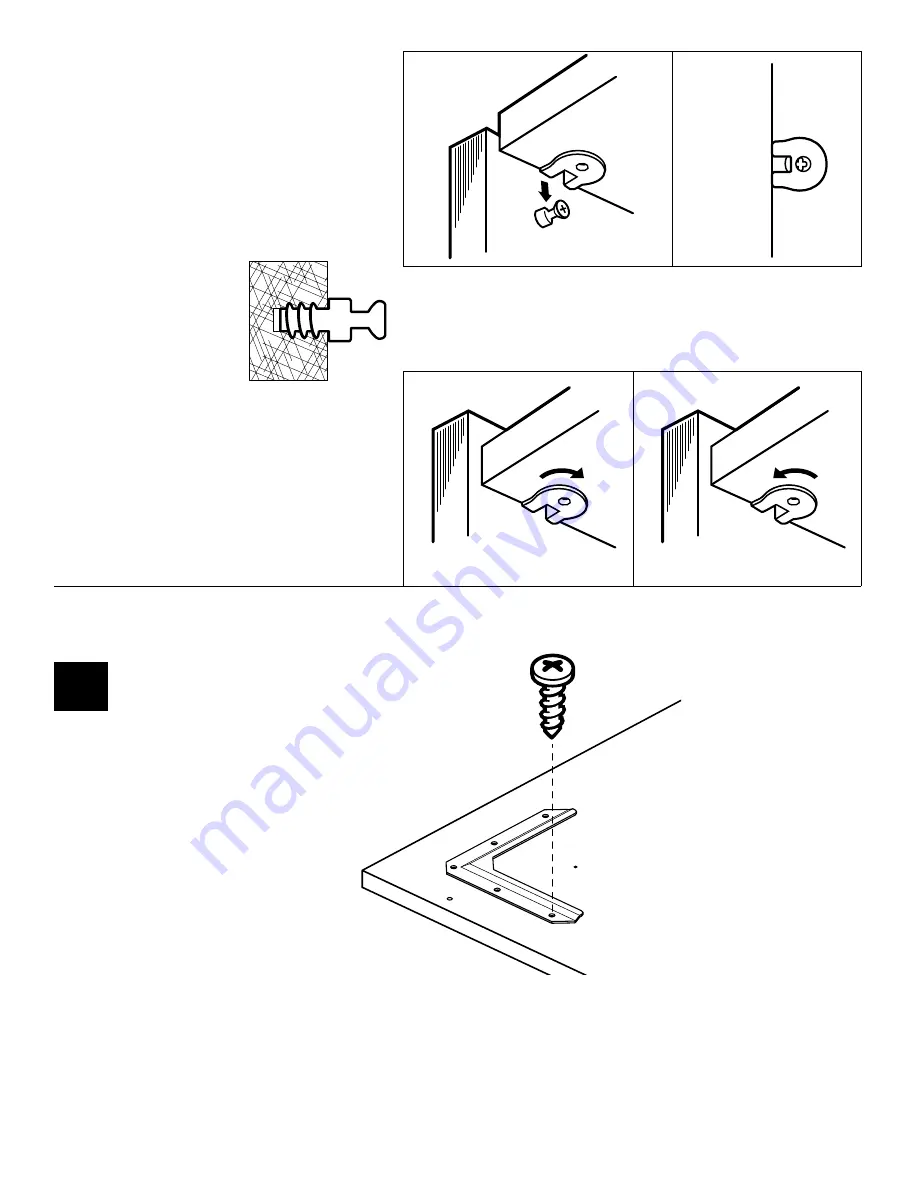

Install two Leg Brackets (H1) at

each corner of the Worksurface

using FIVE Panhead Screws (H2) in

the pre-drilled holes as shown.

#1

C

H1

H2

CCA / CCB

ASSEMBLE

DISASSEMBLE

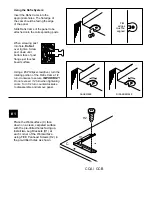

Using the Rafix System:

Insert the Rafix Cams into the

appropriate holes. The flat edge of

the cam should be facing the edge

of the panel.

Slide Rafix Cams of the panel to be

attached onto the corresponding posts.

Using a #3 Phillips screwdriver, turn the

rotating portion of the Rafix Cam a 1/2

turn clockwise to secure.

IMPORTANT!

Do not exceed 1/2 turn when tightening

cams.

Turn 1/2 turn counterclockwise

to disassemble and remove panel.

When screwing post

into hole,

Do Not

over tighten. Screw

post down until

bottom face of post

flange just touches

board surface.

Flat

edges

must be

aligned