Ironwood DBR50 | User Manual

16

7.2 Machine Operation

Step 1:

Activate air supply to machine

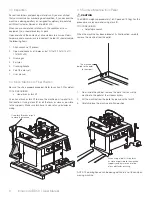

WaRninG

When air pressure is first applied to the machine, the boring head

carriage may move. Do not stand behind the machine.

NOTE: The air supply must be on to make certain adjustments and

enable movement of the workpiece hold-down clamps and boring

carriage.

Step 2:

Turn on power to machine

Step 3:

Ensure air pressure is correct

Step 4:

Select operation mode

There are two operation modes available on the DBR50 machine.

Manual Mode (hand symbol): Use for manual setup of the machine.

Turn the knob to the left for manual control. The boring head

carriage will move pneumatically into the desired position without

spindle rotation, unless spindle rotation is manually turned on.

Automatic Mode (circular arrows): Use for normal machine

operation.

Turn the knob to the right for automatic up/down movement

of the boring head carriages. The foot pedal activates the

pneumatic movement of both the boring head carriages and the

work hold-down clamp. The drill spindles will run automatically

when the boring head carriages move up and stop when they are

in a lowered position.

Step 5:

Set boring depth

Attach the crank handle to the left or right digital readout to set

the boring depth for the back and front carriages. The depths are

displayed in millimeters (mm) on the integral digital readouts for both

controls.

To adjust:

1. Turn the crank handle to change position of boring depth,

observing position on digital readout.

Step 6:

Position rear boring head

The rear boring head can be adjusted to change the spacing

between the front and rear boring heads by using the center digital

readout.

To adjust:

1. Turn the crank handle to change position of the rear boring

head, observing position on the digital readout.

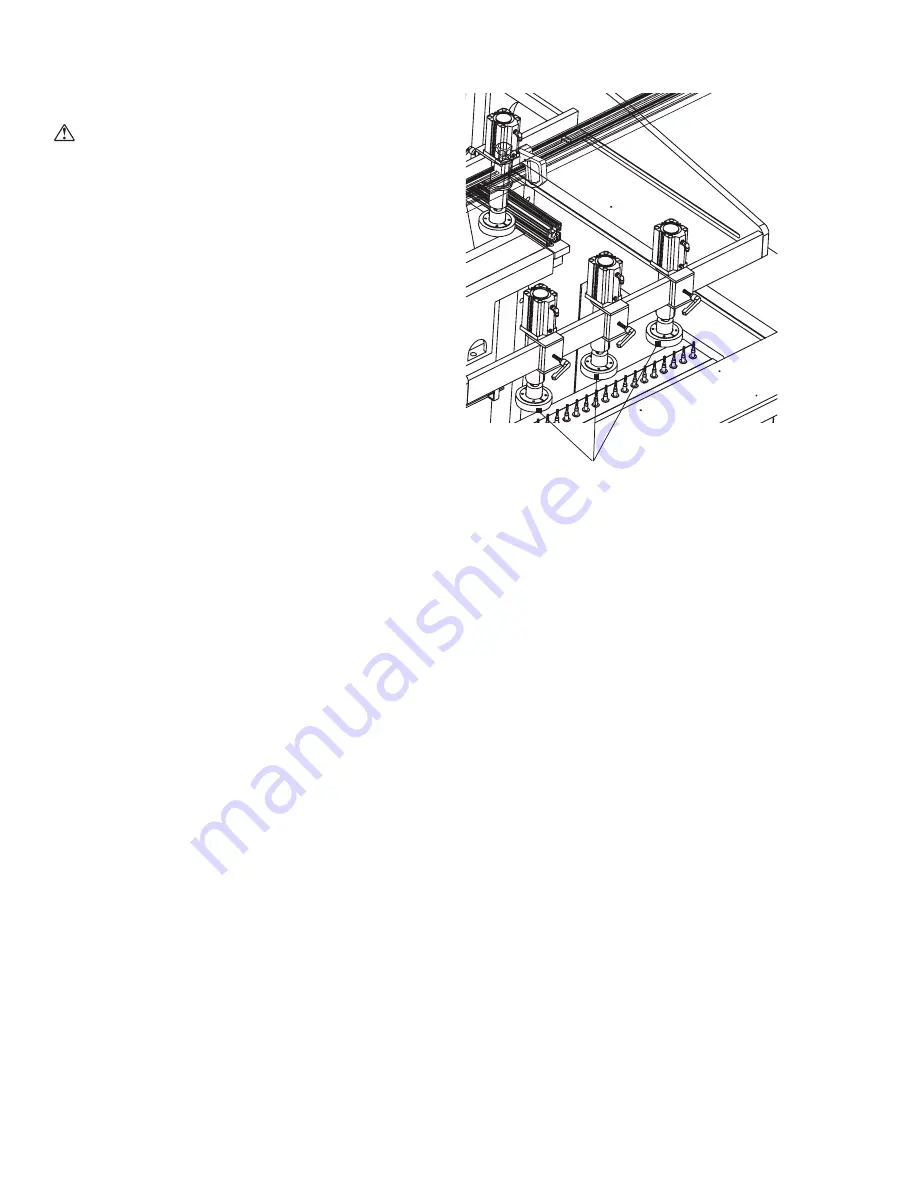

Step 7:

Position the workpiece hold-down clamps

Hold-down clamps

Position the hold-down clamps according to the dimensions of your

workpiece to securely hold it in place while boring.

To accommodate workpiece thickness:

1. Place the workpiece on the table under the hold-down clamps.

2. Lower the hold-down clamps to within an inch of the surface of

the workpiece.

3. Lock the hold-down clamps in place.

To accommodate workpiece width:

1. Loosen the lock lever for each hold-down to be adjusted.

2. Move the hold-down(s) right or left to the optimal position to

secure your workpiece.

3. Tighten the lock levers.

NOTE: A minimum of two workpiece hold-down clamps should

always be used when possible.

To reposition the hold-down assembly:

1. Loosen the lock levers at each end of the assembly.

2. Move the assembly forward or back as needed.

3. Tighten the lock levers.

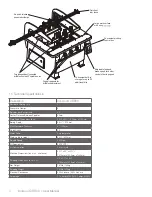

Summary of Contents for DBR50

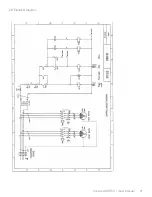

Page 20: ...Ironwood DBR50 User Manual 20 9 1 Air Circuit Diagram...

Page 21: ...Ironwood DBR50 User Manual 21 9 2 Electrical Diagram...

Page 22: ...Ironwood DBR50 User Manual 22 9 2 Electrical Diagram Continued...

Page 23: ...Ironwood DBR50 User Manual 23 9 2 Electrical Diagram Continued...

Page 24: ...Ironwood DBR50 User Manual 24 9 2 Electrical Diagram Continued...

Page 25: ......