Ironwood DBR50 | User Manual

17

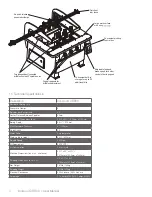

Step 8:

Position flip stops

Position the four flip stops on the fence according to the dimensions

of your workpiece and the desired boring points. The stops can

be moved to any point along the fence. The fence has an integral

measuring guide with magnifying lens for precision set-up.

1. Loosen the flip stop locking levers.

2. Slide the flip stops to the desired positions on the fence.

3. Tighten the locking levers.

Step 9:

Position QuickSet rear fence

A: 37mm stop position

B: 44mm stop position

A

A

B

B

Position the rear fence in proper relation to the drill block for your

application.

1. Loosen the locking handles on the rear fence.

2. Move the fence forward or back as needed.

3. Tighten the locking handles.

Two stop-block positions enable quick and easy 37mm or 44mm

setting:

1. Depress the button on the manual release stop and move to

the desired setting.

2. Release the button.

3. Repeat for the other stop.

Step 10:

Set feed rates

Feed rates are determined by the type of wood and drilling

operation. In general, hard woods require a lower feed rate; soft

woods require a faster rate. Through-holes require a slower rise rate.

To reduce the feed or brake rates for the boring head carriage, turn

the rise rate and brake rate adjustment knobs clockwise for the front

and rear boring head. Turn counterclockwise to increase the feed or

brake rates.

NOTE: If there is burning on a drill hole or chipout on a through-hole,

feed rate is too fast or too slow. Adjust as needed based on the

material being machined.

Step 11:

Boring the workpiece

WaRninG

Do not attempt to operate machine if you are not completely familiar

with its operation. Obtain immediate advice from a supervisor,

instructor, or other qualified personnel.

Use of this machine requires that you give your work your undivided

attention, and careless acts or not paying close attention to work

being performed may result in serious injury to yourself and/or

others. Never operate this or any machine under the influence of

drugs, alcohol, or any medication that may impair judgment.

Do not bore warped wood. The workpiece must sit flat on the table

without rocking.

Dust created by manufacturing activities may be harmful to your

health. Your risks from exposure may vary. Always work in a well-

ventilated area and wear safety approved, protective dust masks

specifically designed to filter out microscopic particles.

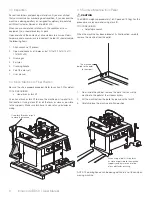

Once fences, depths, and rear boring head are properly set for

operation:

1. Turn on air supply and power supply to machine.

2. Press control power on button.

3. Place the workpiece in the desired reference position against

the fences and/or flip stops.

4. Bore your workpiece:

a. If in manual mode, you should not bore the workpiece.

Switch to automatic mode.

b. If in automatic mode, press the foot pedal; the drill spindles

will run automatically when the boring head carriage moves

up/forward and stop when it returns to the lowered/back

position.

5. Remove the workpiece.

WaRninG

Never remove the bored piece until the boring cycle is complete.

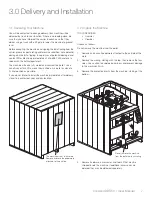

Summary of Contents for DBR50

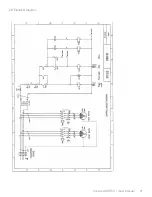

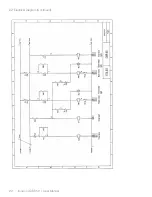

Page 20: ...Ironwood DBR50 User Manual 20 9 1 Air Circuit Diagram...

Page 21: ...Ironwood DBR50 User Manual 21 9 2 Electrical Diagram...

Page 22: ...Ironwood DBR50 User Manual 22 9 2 Electrical Diagram Continued...

Page 23: ...Ironwood DBR50 User Manual 23 9 2 Electrical Diagram Continued...

Page 24: ...Ironwood DBR50 User Manual 24 9 2 Electrical Diagram Continued...

Page 25: ......