Ironwood DBR50 | User Manual

3

1.0 General Information

1.1 Thank You!

Thank you for your purchase of the Ironwood DBR50 double-line

boring machine. At Stiles Machinery, our goal is to ensure that you

are fully satisfied with your purchase. This manual is provided so that

you may properly assemble, operate, and maintain your DBR50.

Should you need help, our team of dedicated service personnel

are available to answer your questions and provide any resource

recommendations you may need.

Warranty and Support

All Ironwood machines are designed to meet the exacting standards

demanded by craftsmen like you. Ironwood machines include a

one (1) year parts warranty and two (2) years of free 24/7 technical

support beginning at date of shipment. Standard technical support

remains in effect for free for the lifetime of the machine thereafter.

Warranty service work is not covered by manufacturer’s warranty.

Stiles’ service team is available for an additional charge.

1.2 Before Contacting Stiles

Please have your machine model and serial number available when

contacting Stiles Machinery with questions. The machine’s model

and serial number are listed on the metallic plate located on the

machine’s frame.

Information regarding the electrical system and pneumatic supply

are also listed on the metallic plate.

Machine information plate

Stiles Technical Support

616.698.6615

Stiles Parts

800.PARTS.80 (800.727.8780)

Website

www.stilesmachinery.com/ironwood/dbr-series

Machine Model ____________________________________________

Machine Serial Number _____________________________________

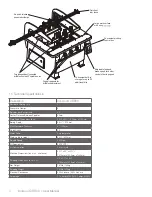

1.3 Features

• 2 independently operated drill blocks have 25 spindles on each

head

• QuickSet rear-fence function allows parallel adjustment of rear

fence to drill block

• 6 Quick-Release pressure-controlled pneumatic clamps firmly

secure workpieces and prevent injury

• Rubber-coated clamping heads prevent workpiece damage

• Convenient pivoting control box

• Adjustable feed and braking speeds for chip-free, through-hole

operation

• Digital readouts for accuracy

• Analog scale (metric and U.S.) allows quick and easy calibration

and are angled for easy viewing

• Second measurement scale is integrated in the rear fence for

precise indexing

• Work table has a large work area

• Compact finish ensures smooth workpiece movement

• Reinforced drill blocks provide additional support for drilling small

workpieces

• Convenient built-in storage for up to 50 additional bits

• Manual-release stops enable quick set ups for 37mm and 44mm

settings

1.4 Intended Use

The Ironwood DBR50 is designed for closet, casegood, and cabinet

making. The machine allows easy boring of single or double rows.

You can bore up to 25 holes in each row with just one stroke.

The machine features two independently operated drill blocks for

vertical drilling. Drill bits rise from beneath the workpiece for faster,

cleaner, and safer boring.

The DBR50 allows System 32 line boring, with hole spacing of

32mm to facilitate the easy installation of dowels, brackets, hinges,

cam fittings, shelf support, connecting screws, etc.

Operators can choose auto or manual mode for repetitive drilling.

This robust, ergonomically designed boring machine allows quick

set-up times, digital read-outs for improved accuracy, and a

conveniently large working surface for various applications.

Summary of Contents for DBR50

Page 20: ...Ironwood DBR50 User Manual 20 9 1 Air Circuit Diagram...

Page 21: ...Ironwood DBR50 User Manual 21 9 2 Electrical Diagram...

Page 22: ...Ironwood DBR50 User Manual 22 9 2 Electrical Diagram Continued...

Page 23: ...Ironwood DBR50 User Manual 23 9 2 Electrical Diagram Continued...

Page 24: ...Ironwood DBR50 User Manual 24 9 2 Electrical Diagram Continued...

Page 25: ......