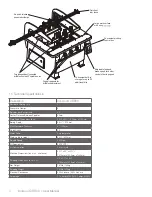

Ironwood DBR50 | User Manual

6

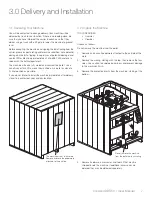

2.0 Facility Preparation

Prior to uncrating your machine confirm that your location can

accommodate the Ironwood DBR50. Follow these guidelines:

2.1 Floor

• The floor must be flat and level.

• Although no special foundations are required, a concrete floor is

recommended.

• All floors must have a load-bearing strength suitable for the

machine weight of approximately 1,600 pounds (730 kg).

• If anchoring the machine to the floor, purchase high quality

anchor bolts appropriate to the floor construction and material.

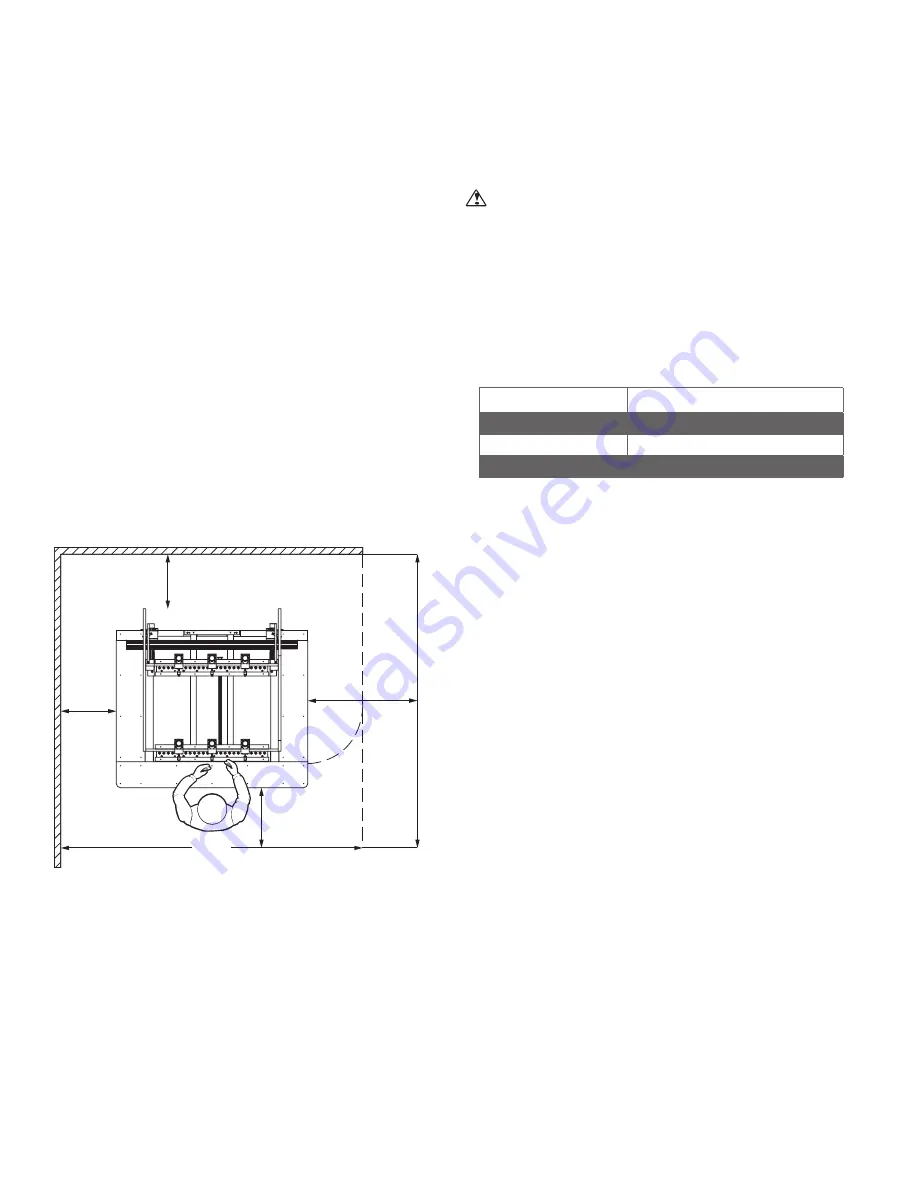

2.2 Work Space

• Provide adequate workspace surrounding the machine.

• Provide proper non-glare, overhead lighting.

• Avoid exposing to any environment where vibration is present.

3'-0"

(900 mm)

3'-0"

(900 mm)

3'

3'

*

*

Machine clearance requirements*

*Actual clearance requirements on the sides depend upon the length

of the workpiece to the machine.

2.3 Power

WaRninG

A licensed electrician must connect the DBR50 to the building

power source.

• Do not use extension cords.

• Be sure that the electrical current of the power source is of

the same characteristics as the 230-volt, or 460-volt, 3-phase

electrical system supplied with your machine. If other machine

voltage capabilities are required, contact Stiles Machinery.

DBR50

Motor

3 hp x 2

Motor Power

230v (3-phase) / 460v (3 phase)

Amperage

17.4 amps @ 230v / 8.7 amps @ 460v

• Ensure the machine is protected with an external over-current

protective device per your local electrical codes.

• Electrical equipment operating conditions:

Air temperatures b41ºF (+5ºC) and +113ºF (+45ºC).

Relative humidity not to exceed 50% at a maximum temperature

of +113ºF (+45ºC).

• Electrical equipment is designed and protected to withstand the

effects of transportation and storage temperatures within a range

of -13ºF (-25ºC) to +131ºF (+55ºC), and for short periods of time

not exceeding 24 hours at up to +158ºF (+70ºC).

• Ensure connection to factory ground system is wired correctly

(IAW local electrical codes and NEC) and not connected to any

electro magnetic interference source such as welders.

2.4 Compressed Air

This machine requires compressed air between 90-100 psi to

operate.

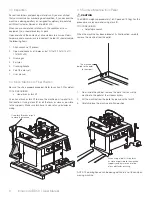

Summary of Contents for DBR50

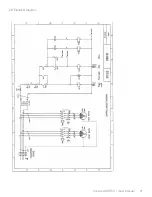

Page 20: ...Ironwood DBR50 User Manual 20 9 1 Air Circuit Diagram...

Page 21: ...Ironwood DBR50 User Manual 21 9 2 Electrical Diagram...

Page 22: ...Ironwood DBR50 User Manual 22 9 2 Electrical Diagram Continued...

Page 23: ...Ironwood DBR50 User Manual 23 9 2 Electrical Diagram Continued...

Page 24: ...Ironwood DBR50 User Manual 24 9 2 Electrical Diagram Continued...

Page 25: ......