Cast Iron Joining Instructions

Cast Iron Joining Instructions

Please note:

that after manufacture these radiators are pressure tested and cleaned

inside, they may, therefore, contain a small amount of water. If handling on a finished floor

ensure that adequate protective material is in place before working on the radiators.

A minimum of two people are required to join these sections to ensure safe handling of

the radiators and to facilitate an effective water tight seal.

You will need: two nipples, 2 gaskets per join, appropriate size joining key, extension rod

for extra torque, bushes and gaskets.

Cast Iron radiators have specific left and right hand threaded bushes and these

can be easily damaged if forced or incorrectly fitted (this will inevitably cause

leaks). Bushes require a dry fit connection only; you must not use any Compound

materials (e.g. Jet Blue) or Plumbers Hemp. It is important for the faces and

flanges of the bushes to be free from and rust/residue/particulates.

To facilitate the joining process the radiator sections must be raised off the ground, (on a

firm flat surface) to allow the joining key to turn freely. The radiators should not be placed

upright or on end when joining.

1.

Before joining the radiators together please remove the

plastic bungs, radiators have colour coded plastic inserts to

aid in joining the correct end.

2.

Position all sections to be joined the correct way up; place

the end with a rough casting finish along the join at the

bottom and the end with the smooth cast finish at the top.

The radiators also need to be the correct way round; ensure

the same trade mark or manufacturers stamp are all facing

the same way. (Image 1 & 2)

3.

Top smooth edge

Image 1

Bottom rough edge

Image 2

Clean the surfaces to be joined using a small blade or similar to remove any dirt or

deposits from the face and screw thread.

4.

The radiator sections and joining nipples have one left and one right hand thread the

Nipples must be inserted correctly to avoid cross threading.

5.

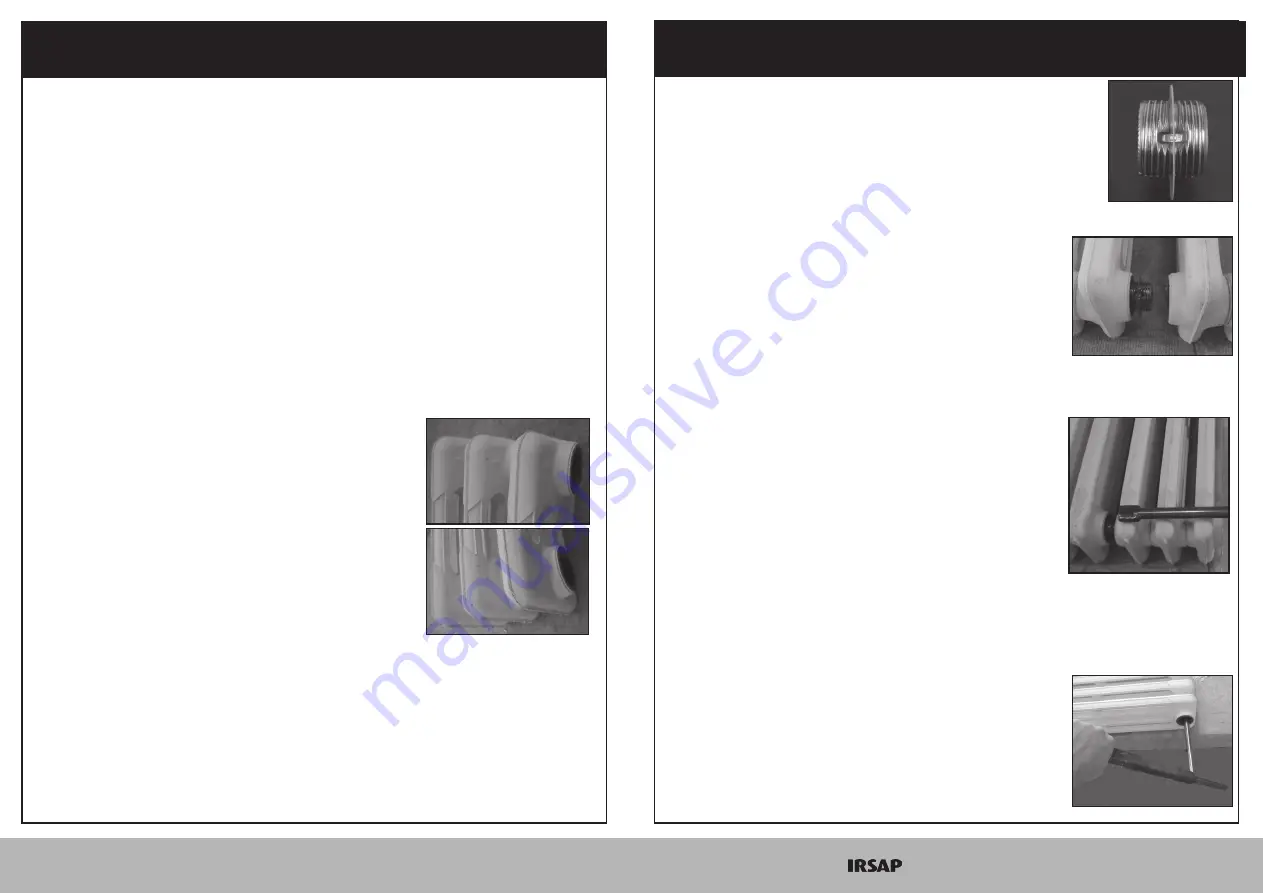

Fit a graphite joining gasket over each nipple; push them

carefully onto the nipple, making sure they do not tear, until

they sit in the groove in the middle of the nipple. (image 3)

Image 3

Having identified the correct insertion direction, using 1

hand turn only screw in a pair of nipples into the end of one

radiator (screwing the nipple in further at this stage may

cause problems obtaining a water tight seal.) (Image 4)

Image 4

Offer up the second radiator, making sure that the two

nipples enter the second section evenly.

Measure the distance required for the key to identify how far

in you need to place the key and then insert the key through

the open end of the water way to locate the lug within the

first nipple to be joined. (Image 5)

Image 5

Image 6

The two nipples should now be tightened alternatively

to keep the radiators parallel. The key should be kept in

a central position in the waterway whilst turning. Tighten

the first nipple with 2 turns only, pulling the two sections

together. Repeat the process alternating between nipples,

until both sections are joined hand tight.

Once the joins have been hand tightened both will need

extra torque applied to make a water tight seal. To obtain

this use a metal extension rod to apply greater leverage.

(image 6)

Once the joins are satisfactorily tightened you can fit the

blanking plugs, bushes and gaskets. Please note these items

are also left and right handed to avoid cross threading.

6.

7.

8.

9.

10.

11.

12.

If you have any questions please contact us: 01342 302250, www.theradiatorcompany.co.uk

A brand of , Italy’s leading manufacturer of design led radiators