-It is essential for the safety of the user that if the product is re-sold outside the original country of destination the

reseller shall provide instructions for use, for maintenance, for periodic examination and for repair in the language of

the country in which the product is to be used.

LIFETIME

The estimated product lifetime is unlimited. The following factors can reduce the lifetime of the product : intense use,

contact with chemical substances, specially agressive environment, extreme temperature exposure, UV exposure,

abrasion, cuts, violent impacts, bad use or maintenance.

The required annual examinations will validate the correct functioning of the equipment. It is compulsory that the

equipment is examined by the manufacturer or his authorized representative at least once a year.

In case that it have been used to arrest a fall, the equipment must be withdrawn from use.

TRANSPORT

The equipment must be transported in a package that protects it against moisture or mechanical, chemical and thermal

attacks.

INSTRUCTIONS FOR MAINTENANCE

-

CLEANING: The personal protective equipment must be cleaned without causing adverse

effect on the materials used in the manufacture of the equipment. For textile (webbing and ropes) and plastic parts wipe

with cotton cloth or a soft brush. Do not use any abrasive material. For intensive cleaning wash the harness at a

temperature between 30ºC and 60ºC using a neutral detergent. For metallic parts wipe with a wet cloth. When the

equipment becomes wet, either from being in use or when due to cleaning, it shall be allowed to dry naturally, and shall

be kept away from direct heat.

-

STORAGE: Personal protective equipment should be stored loosely packed, in a dry and

well - ventilated place, protected from direct light, UV degradation, dust, sharp edges, extreme temperature and

aggressive substances.

REPAIR

Any repair shall only be carried out by equipment manufacturer or his authorized representative following

manufacturer’s procedures.

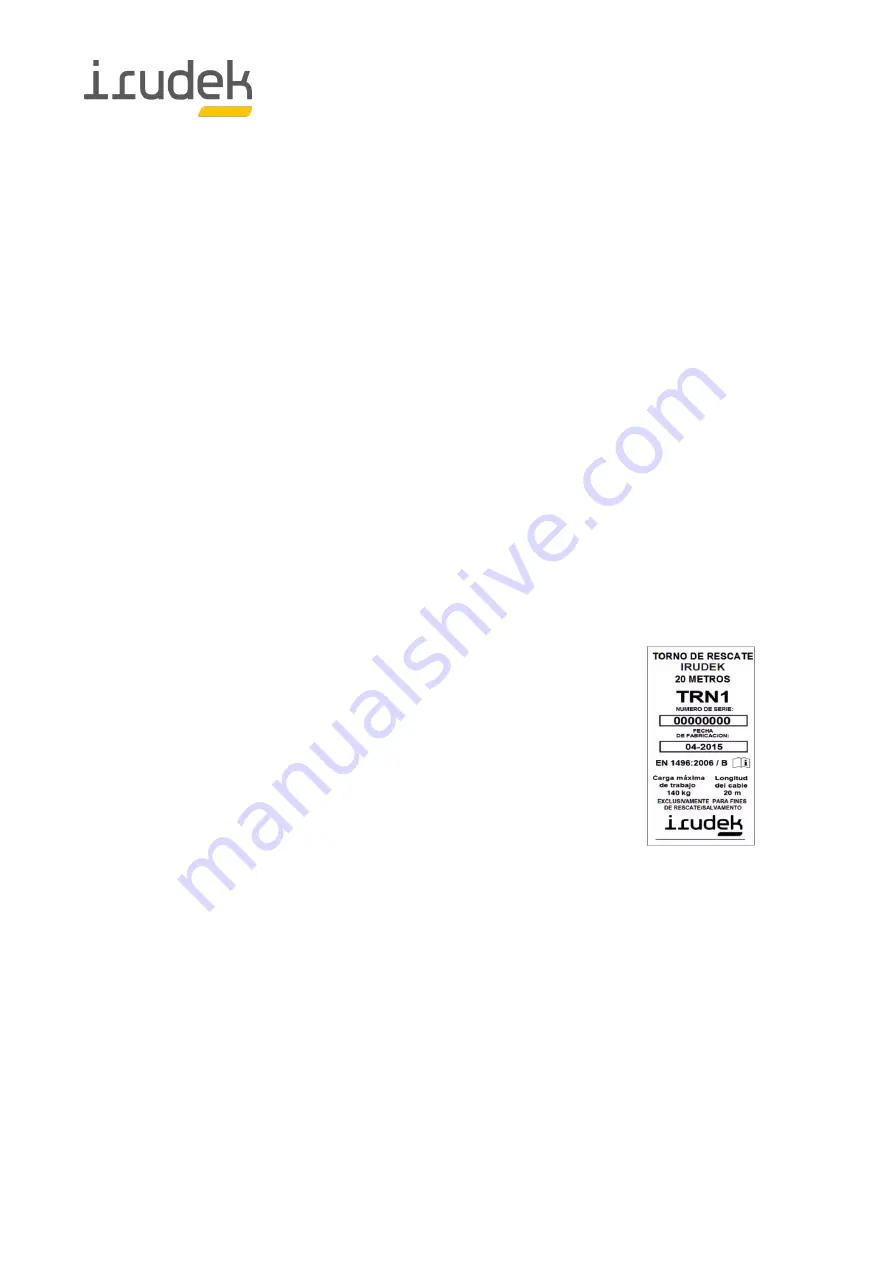

MARKING

The equipment is marked with the next information:

i) Identification of the manufacturer

ii) Reference of the equipment

iii) Lot/serial number

iv) Year of manufacture

v) Maximum load capacity

vi) Length

vii) European Norm

viii) Pictogram to indicate the necessity for user to read the instruction for use

INSTRUCTIONS FOR PERIODIC EXAMINATIONS

It is necessary to carry out regular periodic examinations. The safety of the users

depend upon the continued efficiency and durability of the equipment.

The equipment shall be examined at least every 12 months. The periodic examination

can only be carried out by the manufacturer or his authorized representative.

The comments should be included in the check card of the equipment. After the

periodic examination, the next due date for periodic examination will be determined.

During periodic inspection it is necessary to check the legibility of the equipment

Marking.

CHECK CARD

The check card should be filled in before the first use.

All information about the equipment ( name, serial number, date of purchase and date of putting into operation, user

name, periodic examination and repair history, and next periodic examination date ) shall be noted into de check card.

All records in the check card can only be filled in by a competent person.

Do not use the equipment without a duly filled check card.