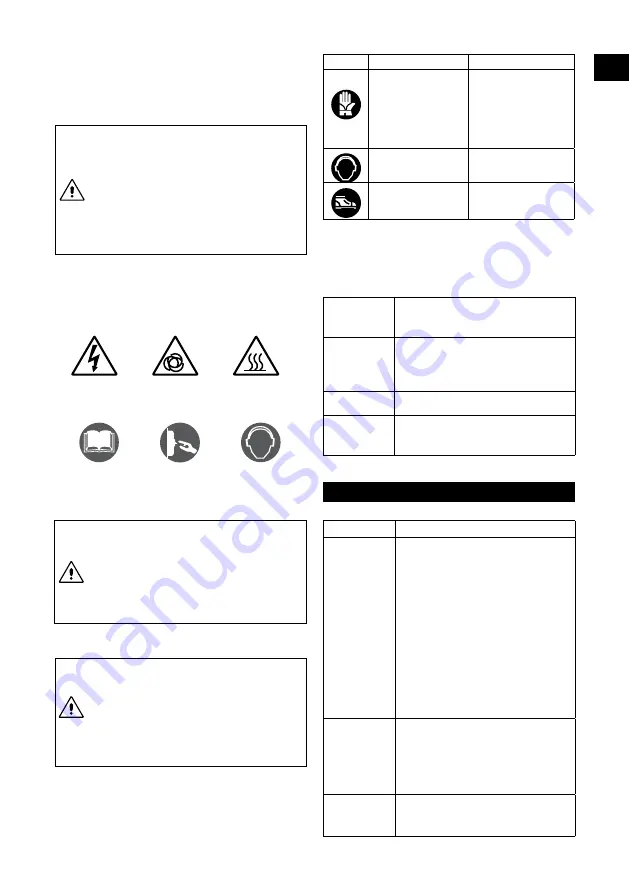

SAFETY MARKING

The safety marking used is represented by an adhesive label,

applied on the outside of the machine.

Meaning of the signals:

bar

0

Hazard:

Power supply

Hazard:

Automatic start

Hazard:

High temperature

Read the

instructions

compulsorily

It is compulsory to

disconnect power

supply

It is compulsory to

protect the hearing

It is compulsory to keep the safety signal well clean

to ensure their good visibility.

It is absolutely forbidden to remove and/or damage

the safety signals applied to the machine.

It is compulsory to replace the safety signals worn

out requesting to the manufacturer and/or authopized

dealer.

SIGNAL COMPULSORY PPE

TYPE OF USE

Hands Protection

(Heart protecting

gloves)

In case maintenance

interventions are

required without

waiting that the

electric motor and the

bi-cylindrical pumping

element cool down.

Hearing Protection

(Ear muff)

During all processing

phases.

Feet protection

(Footwear with

reinforced cap)

During machine

transport.

PERSONAL PROTECTION EQUIPMENT (PPE)

The authorized operators are not allowed to wear

cloths and accessories that may be entangled in the

machine.

It is compulsory to use the ppe foreseen by the

manufacturer.

The authorized operators must compulsorily use the

ppe foreseen by the manudacturers of the tools used

and according to the processing type.

compressed air pressure present within the tank.

6.

PRESSURE GAUGE AT OUTPUT: this is a measuring device

installed on the machine pneumatic plant upstream of the

fast air outlet tap. It displays the output pressure, which is

adjustable through the proper pressure regulator (0 ÷ 10 bar).

It is strictly to tamper, disconnect and/or remove any

safety device existing in the machine.

It is strictly forbidden to replace any safety device or

any of their components with not original spare parts.

It is compulsory to constantly check the correct

operation of all safety devices installed on the

machine.

It is compulsory to immediately replace any safety

device malfunctioning and/or being damaged.

RESIDUAL RISKS

The authorized operators shall be aware that even

though the manufacturer has adopted all possible technical

manufacturing precautions to make the machine safe, there is

still a potential residual risk.

RESIDUAL

RISK

Hazard of burning by accidental contact

with the bi-cylindrical pumping assembly

and the electric motor.

EXPOSURE

FREQUENCY

Low and accidental. There can be

exposure if the operator decides to perform

voluntary a wrong action, forbidden and not

reasonably foreseeable.

DAMAGE

RELEVANCE

Light lesions (usually reversible).

DAMAGE

RELEVANCE

Safety sings. / Obligation of use of the

personal protection equipment (PPE) and/

or wait until the machine has cooled.

MACHINE USE

DESTINATION OF USE

FIELD OF USE

Industrial, raft and civil sector.

PLACE OF

USE

Indoor or outdoor (provided that it is

not subject to atmospheric agents)

sufficiently lighted, ventilated, with ambient

air temperature and humidity values

complying, suitable in compliance with

the law provision in force in the country

of use on safety and health in the places

of work. The machine has to lean on a

surface assuring its stability with reference

to its weight and its overall dimensions.

CAUTION IT IS COMPULSORY

TO KEEP THE MACHINE OUT OF

THE REACH OF CHILDREN.

FORESEEN

USE

Air compression (without oil) for the use

of suitable pneumatic tools complying

with the regulations in force. (ex:

guns for blowing, inflation, washing,

painting or sandblasting; screwers;

spot welders, riveters or greasers).

OPERATORS

CHARGED

WITH THE

USE

An authorized operator meeting the

professional requirements described.

5

EN