sAFEty WARNiNGs

y

y

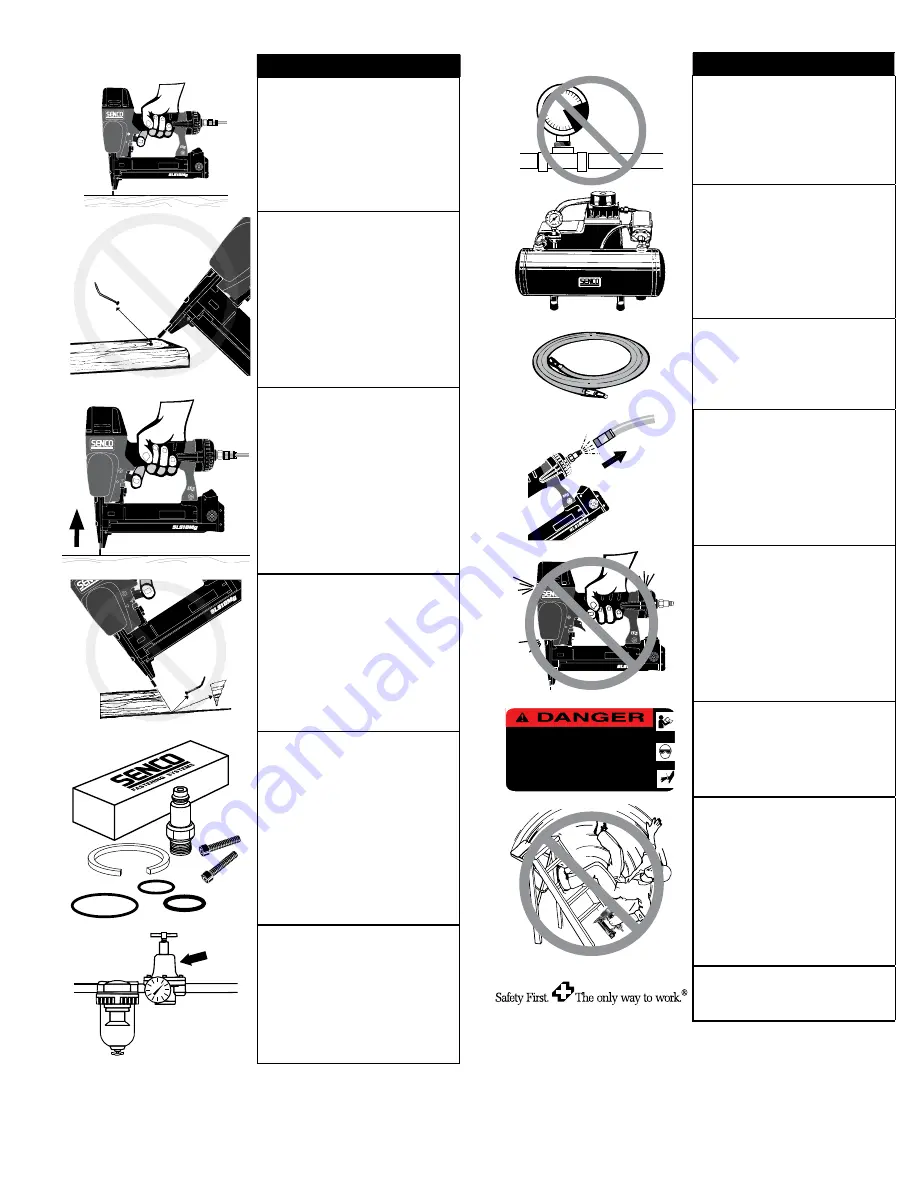

Drive fasteners into work surface

only; never into materials too

hard to penetrate.

y

y

Do not drive fasteners on top of

other fasteners or with the tool at

too steep of an angle; the fasteners

can ricochet and hurt someone

.

y

y

When using tool, care should be

taken due to possibility of tool

recoil after a fastener is driven.

If safety element is unintention-

ally allowed to re-contact work

surface following a recoil, an

unwanted fastener will be driven.

Therefore, allow tool to recoil

completely off work surface after

a fastener is driven to avoid this

condition. Do not push safety

element on work surface until a

second fastener is desired.

y

y

Do not drive fasteners close to

the edge of the work surface.

The workpiece is likely to split

and the fastener could fly free or

ricochet and hit someone.

®

y

y

Use only parts, fasteners, and ac-

cessories recommended or sold by

SENCO. Do not modify tool without

authorization from SENCO.

y

y

Use only clean, dry, regulated

compressed air at recommended

pressure.

sAFEty WARNiNGs

200 psig

13.7 bar

yy

Do not connect tools to air pressure

that potentially exceeds 200 psig

or 13.7 bar.

yy

Air compressors used to supply

compressed air to this tool must

comply with requirement ANSI/

ASME B 19.1–1995 (U.S.),

“Safety Standard For Air Com-

pressor Systems.”

yy

Air hose must have a minimum

working pressure rating of 150

psig (10.3 bar) or 150% of the

maximum pressure produced in

the system, whichever is higher.

yy

The tool and air supply hose

must have a hose coupling such

that all pressure is removed from

the tool when the coupling joint

is disconnected.

yy

Never use a tool that leaks air or

needs repair.

1. Read and understand tool labels and manual. Failure to follow

warnings could result in DEATH or SERIOUS INJURY.

2. Operators and others in work area MUST wear safety glasses with

side shields.

3. Keep fingers AWAY from trigger when not driving fasteners to

avoid accidental firing.

4. Choice of triggering method is important. Check manual for

triggering instructions.

5. NEVER point tool at yourself or others in work area.

6. NEVER use oxygen or other bottled gases. Explosion may occur.

7. MAX AIR PRESS. 120 PSI (8.3 BAR)

yy

Do not use tool without danger

label on tool. If label is missing,

damaged or unreadable, contact

your SENCO representative to

obtain a new label.

yy

Always place yourself in a firmly

balanced position when using or

handling the tool.

yy

For information on the “SENCO

Safety First Program,” contact

your SENCO

representative.