tool usE

y

y

Read section titled “Safety Warn-

ings,” before using tool.

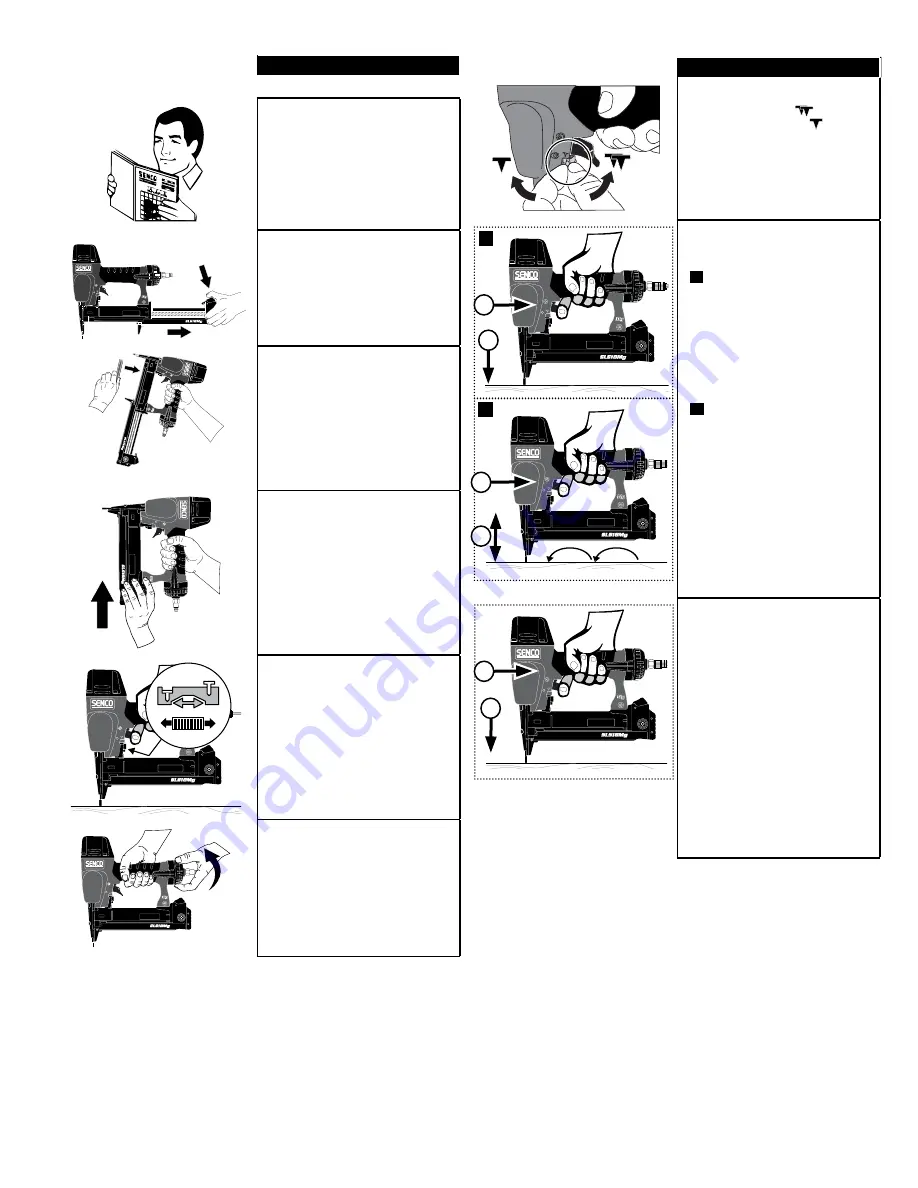

to load:

y

y

Depress latch and slide rail

open..

y

y

Lay strip of staples into maga-

zine. Use only genuine SENCO

staples. Do not load with trigger

depressed.

y

y

Push rail forward until it latches.

to adjust the depth the fastener

is driven:

y

y

First disconnect the air supply.

y

y

Using your thumb or index

finger, rotate wheel to adjust the

Depth Control workpiece contact

(safety element) to achieve

desired depth.

to adjust the direction of the

exhaust air:

y

y

Turn the exhaust deflector to the

desired location.

tool usE

yy

These tools have an adjust-

able trigger and can be set for

) or

Contact Actuation (

Sequential Actuation (

).

yy

With a “Contact-Actuation”

(Dual-Action) trigger, nails can

be driven two ways:

A

First,

position safety

element against work surface,

then

k

pull trigger — “Trigger

Fire.”

B

First,

pull trigger, then

k

push safety element against

work surface for operation

each time the safety element

is pushed against the work

surface. This “bottom-fire” mode

of operation is preferred when

high speed, rapid fastener

placement is desired.

yy

With a “Sequential” (Restrictive)

trigger, nails can only be driven

one way. First,

position safety

element against work surface,

then

k

pull trigger. This feature

is helpful when precise fastener

placement is required.

Read the “Customer Satisfaction

and Safety Reminder” (CSSR)

in the tool and fastener boxes

for safety information regarding

the Dual Action and Restrictive

triggers. Under certain condi-

tions, the Restrictive trigger may

reduce the possibility of injury

to you or to others working with

you.

2

1

B

1

2

A

1

2