VI. PRE-OPERATIONAL ROUTINE INSPECTION

41

VI. PRE-OPERATIONAL ROUTINE INSPECTION

It is essential for avoiding accidents or breakdown during operation to keep the lawn mower in goon condition. The

following pre-operational checks should be performed without fail before starting daily operation.

2. WAY OF INSPECTION AND MAINTENANCE

Refer to the section of “MAINTENANCE.”

WARNING: Before inspection, be sure to

park the lawn mower on a level and hard

ground, stop the engine, lower the mower

deck onto the ground, remove key from the

starter switch, apply the parking brake (GE

TYPE) or the parking lock (E TYPE), move

the PTO lever to the OFF ( ) position, and

check to see that the mower blades have

completely ceased rotating.

Machine weight balance is a very important

factor for safe operation. When your machine

is equipped with an implement such as a

cabin, etc., never fail to ask your dealer about

machine balance. Always follow their advice.

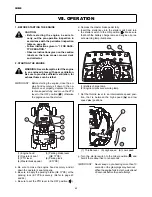

1. INSEPCTION ITEMS

(1) Anything that was abnormal in the previous operation.

(2) While walking around the lawn mower:

• Tire inflation

• Exterior parts (broken or deformed covers or the like)

• Oil leakage (engine oil, transmission oil, fuel, etc.)

• Inspection and cleaning of air-intake port

• Inspection of engine oil level

• Inspection of coolant level

• Inspection of fan belt

• Inspection of fuel level

• Inspection of fuel filter

• Inspection of transmission oil level

• Inspection of front and rear wheel tightening bolts

and nuts

• Inspection of rear axle chain case oil level

• Cleaning of radiator and radiator screen

• Inspection of electrical apparatus

• Inspection of mower blades

• Inspection of mower-blade driving belt

• Inspection of mower exterior parts like covers for

damage and deformation

• Oil leakage from mower gear case

• Inspection and cleaning of gauge wheels

• Inspection for loose broken or lost bolts and nuts

• Inspection for loose, broken or lost pins and clips

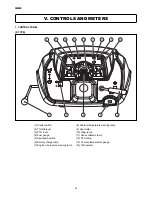

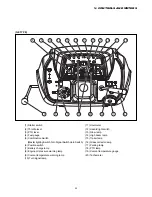

(3) While sitting in the operator's seat:

• Inspection of brake

• Adjustment of seat

(4) After having started the engine:

• Confirmation of the operation of safety switches

• Inspection of the operation of the steering wheel

Summary of Contents for SBC550X

Page 71: ...SXG 70 ...

Page 72: ...XI ELECTRIC WIRING 71 XI ELECTRIC WIRING E TYPE ...

Page 73: ...72 SXG GE TYPE ...

Page 103: ...SBC600XH SBC550XL 102 ...