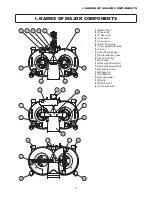

IV. INSPECTION AND MAINTENANCE OF MAJOR PARTS

85

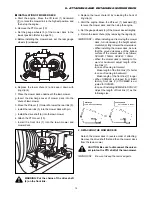

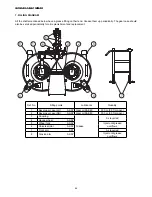

4. INSPECTION OF GAUGE WHEELS

As the gauge wheels are installed on the rear ends of

the mower deck, they are more vulnerable to being hit

and deformed by obstacles than any other part. When

a gauge wheel (1) does not turn smoothly or is de-

formed, replace it with a new gauge wheel immediately.

(1) Gauge wheel

5. INSPECTION OF ROLLERS

Make sure that the rollers (1) turn smoothly.

(1)

Roller

IMPORTANT: • When the gauge wheels and rollers are

hard to turn, disassemble them and

clean them.

• After re-assembly, be sure to grease

them sufficiently:

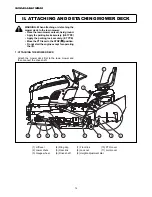

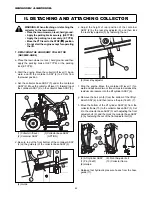

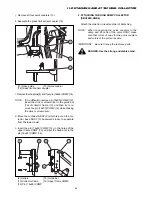

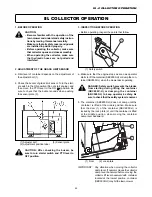

6. CLEANING OF MOWER DECK

a. Remove belt cover, and clear the grass and dust ac-

cumulated under the cover before operation, or short-

er service life of the belts and damage to bearings and

oil seals will be caused.

CAUTION: Be sure to replace the removed

cover after cleaning.

(1) Water hose plug

b. Pour the water into mower deck from water hose

plugs (1) and turn the blade.

c. After mowing, clear the underside of the mower deck

and blades of accumulated grass and dirt. Especially

after operation in wet grass, wash them without fail,

or accumulated wet grass and dirt will cause perfor-

mance deterioration.

CAUTION: When pouring the water into

mower deck to clean, be sure to make revo-

lution of engine low.

1

1

1

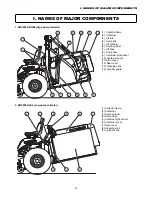

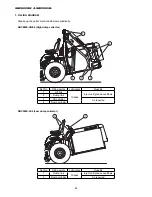

Summary of Contents for SBC550X

Page 71: ...SXG 70 ...

Page 72: ...XI ELECTRIC WIRING 71 XI ELECTRIC WIRING E TYPE ...

Page 73: ...72 SXG GE TYPE ...

Page 103: ...SBC600XH SBC550XL 102 ...