11

CHAPTER 2. DISASSEMBLY OF MAJOR COMPONENTS

• Use a lithium-based grease.

• There should be no oil or water leaks through

the installed soil seals.

c. O-rings

• O-rings should be coated with grease before in-

stalling.

• Installed O-rings should have no slack or twist.

• Installed O-rings should maintain proper air

tightness.

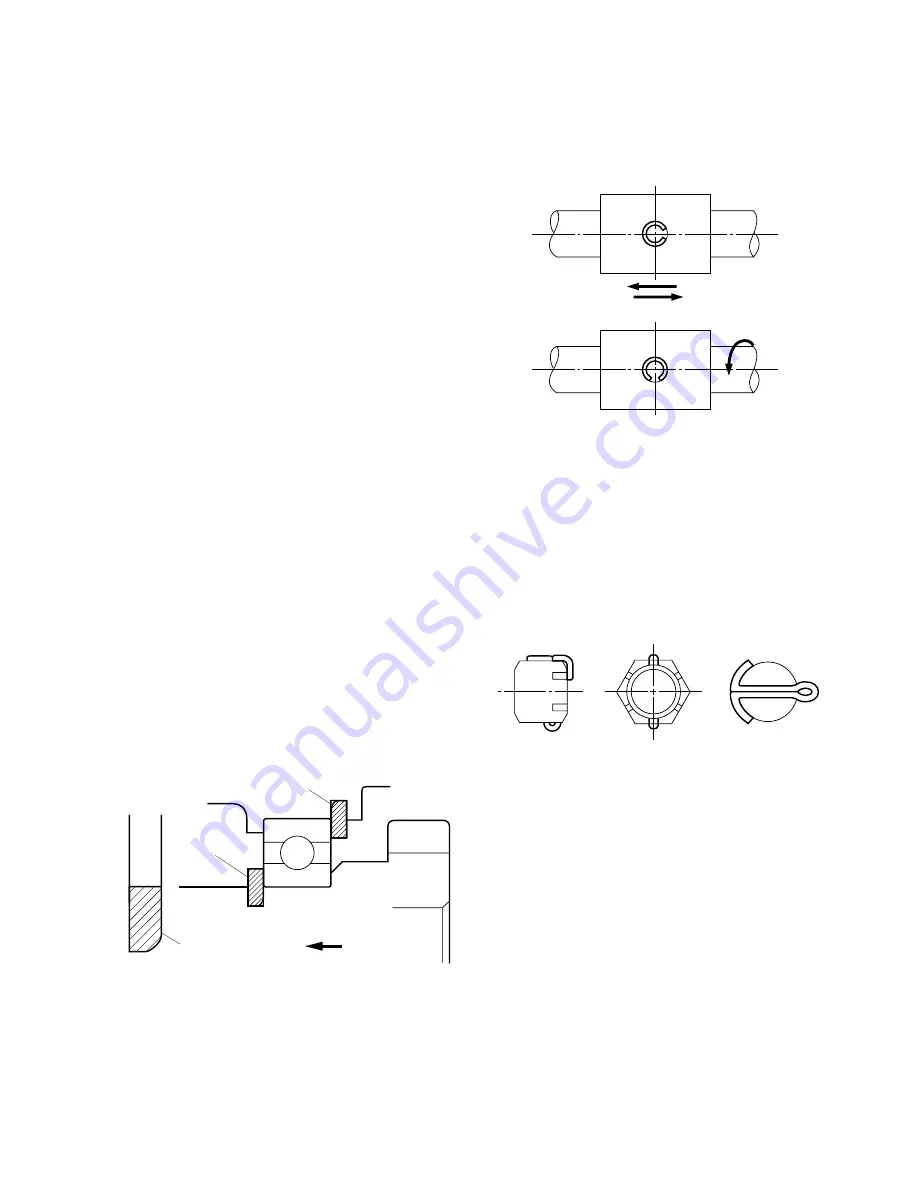

d. Snap-rings

• Snap-ring installers should be designed so as not

to permanently deform the snap-rings.

• Installed snap-rings should be seated securely

in the groove.

• Be careful not to overload the snap-ring to the

extent that it is permanently deformed.

• How to install the snap-ring:

When installing a snap-ring, install it as shown

in the figure with its round edge side turned to-

ward the part to be retained. This round edge is

formed when the snap-ring is pressed out.

Fig. 2-1

e. Spring (roll) pins

• Spring pins should be driven in properly and

tightly.

• Spring pins should be installed so that their seams

should face the direction from which the load is

applied.

Fig. 2-2

• The roll pins installed in the transmission or other

parts where much force is applied should be re-

tained with wire.

f. Cotter pins

• When installed, cotter pins should be bent se-

curely at the ends as shown in the figure.

Fig. 2-3

g. Bolts and nuts

• Special bolts are installed at several locations,

so be sure not to interchange them other bolts.

• Bolts and nuts should be tightened to their speci-

fied torque with a torque wrench.

• When locking the bolts or nuts with wire or a

lock washer, be sure to wind the wire paying suf-

ficient attention to its winding direction and bend

the lock washer for secure locking.

• When locking bolts and nuts with an adhesive,

apply the adhesive on the thread and tighten se-

curely.

Snap-ring

Snap-ring

Round edge side

Thrust force

F

F

F

Summary of Contents for SCM49

Page 1: ...S E R V I C E M A N U A L I S E K I L A W N M O W E R S LAWN MOWERS MOWER DECKS SCM48 SCM54 ...

Page 7: ...7 CHAPTER 1 INTRODUCTION 3 EXTERIOR VIEW AND DIMENSIONS 1935 mm 1965 mm 1100 mm 1265 mm ...

Page 36: ...36 SERVICE MANUAL FOR SGR19 SGR17 Fig 3 55 III 3 CYLINDER BLOCK 1 EXPLODED VIEWS ...