32

SERVICE MANUAL FOR SGR19 & SGR17

Standard value

Usable limit

Clearance

0.01 – 0.05 mm

0.2 mm

Fig. 3-39

(5) Reassembly of the rocker arm shaft assembly

• Arrange the rocker arms so that the sides where

identification markings were put when disas-

sembled are turned forward. Make sure that the

shaft is placed with the end having an off-set

positioning bolt hole turned forward.

Fig. 3-40

5. INSPECTION OF THE PUSH RODS

• Check both ends of each push rod for wear.

Replace excessively worn rods with new ones.

• Check push rods for bending.

Place a rod on a surface table and measure bend-

ing with thickness gauges.

Usable limit

Push-rod bending

0.3 mm

Fig. 3-41

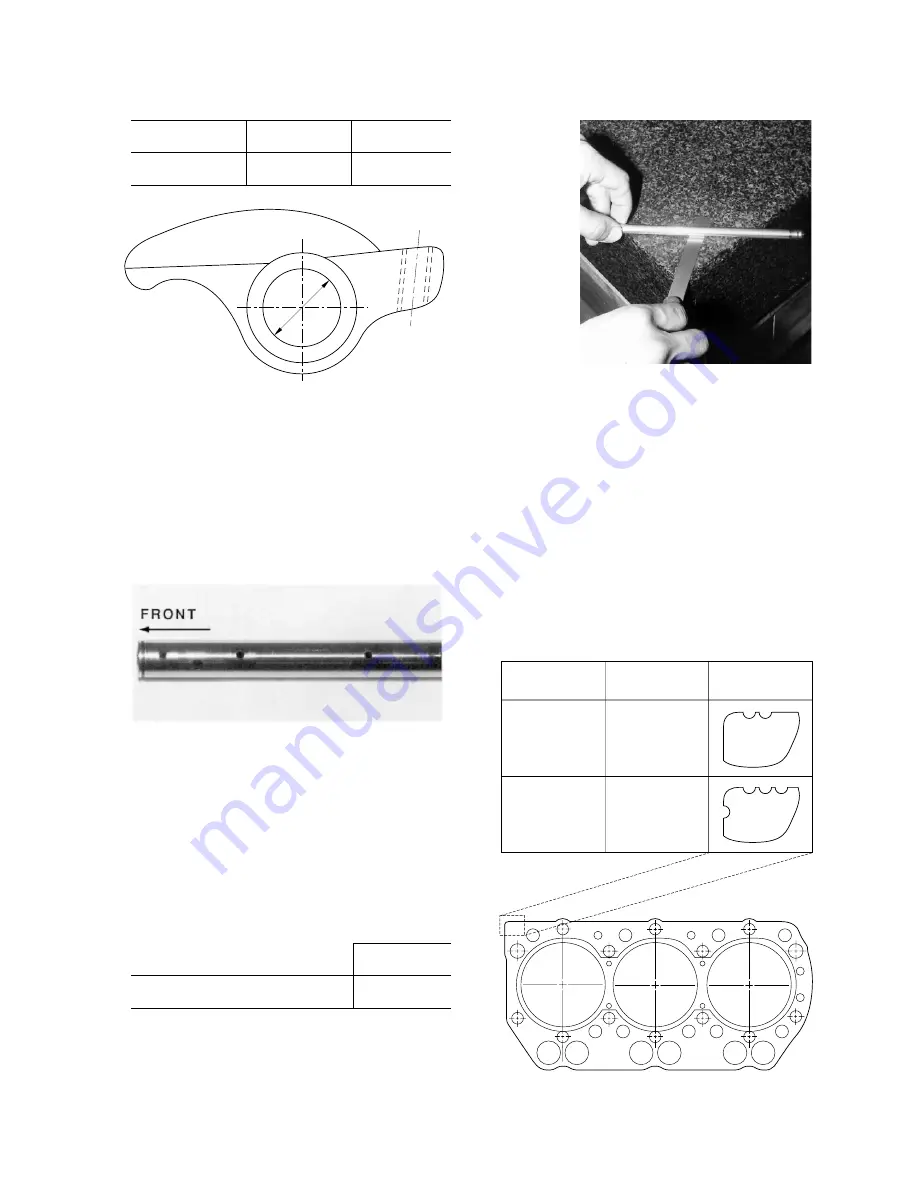

6. INSTALLATION OF THE CYLINDER HEAD

(1) Installation of the cylinder head

• Clean the bottom surface of the cylinder head

and the top surface of the cylinder block.

• Drive in dowels.

• Insert tappets.

• Put a new gasket with its “TOP” mark turned

upward.

• A gasket of different models has a different iden-

tification marking: notches in the left top cor-

ner as shown below.

Engine model

Cylinder bore

(mm)

Identification

notches

E393

E383

Ø74

Ø70

Fig. 3-42

Summary of Contents for SCM49

Page 1: ...S E R V I C E M A N U A L I S E K I L A W N M O W E R S LAWN MOWERS MOWER DECKS SCM48 SCM54 ...

Page 7: ...7 CHAPTER 1 INTRODUCTION 3 EXTERIOR VIEW AND DIMENSIONS 1935 mm 1965 mm 1100 mm 1265 mm ...

Page 36: ...36 SERVICE MANUAL FOR SGR19 SGR17 Fig 3 55 III 3 CYLINDER BLOCK 1 EXPLODED VIEWS ...