38

SERVICE MANUAL FOR SGR19 & SGR17

(15) Removal of the flywheel.

• Chock the flywheel.

• Removal of the flywheel.

Fig. 3-60

(16) Remove the rear plate.

(17) Removal of the crankshaft.

• Remove bearing caps.

Fig. 3-61

• Put aside removed bearing caps and bearings in

order of bearing numbers.

• Remove the crankshaft.

(18) Remove the oil pressure switch.

3.

INSPECTION OF CYLINDER BLOCK,

CRANKSHAFT, CAMSHAFT, AND

TAPPETS

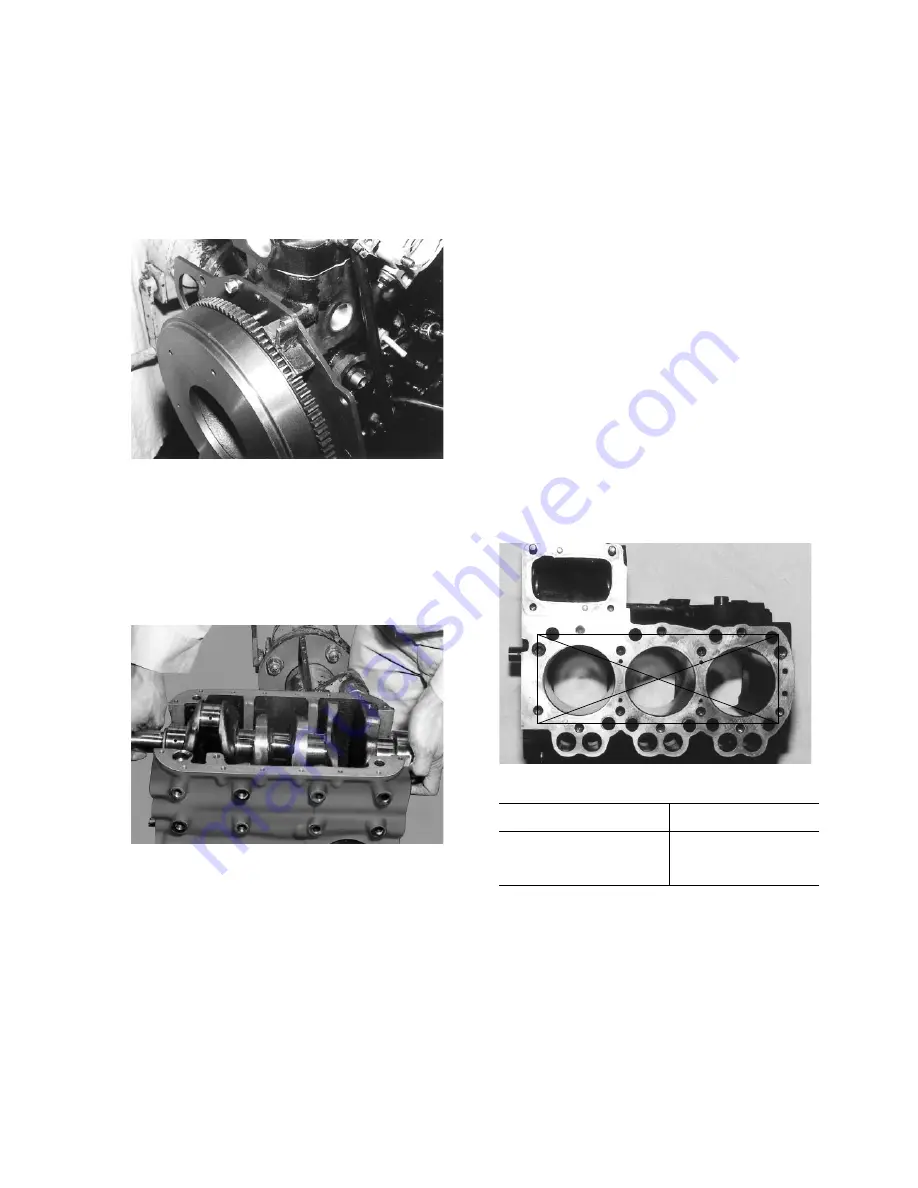

(1) Inspection of the cylinder block

• Inspect the cylinder block for damage.

Check for damage visually.

Use “COLOR CHECK” if necessary to check

for cracks and other damage. Repair damage if

possible or replace.

• Inspect the cylinder block top surface for flat-

ness.

Check the top surface for distortion with a

straight rule and thickness gauges in diagonal

ways as shown in the figure.

Fig. 3-62

Standard value

Usable limit

0.08 mm

0.15 mm

or less

If distortion exceeds the usable limit, correct on

a surface grinder. But the ground-down limit is

0.4 mm. A cylinder block which cannot be cor-

rected within the ground-down limit should be

replaced with a new one.

• Check the cylinder bores for wear.

Summary of Contents for SCM49

Page 1: ...S E R V I C E M A N U A L I S E K I L A W N M O W E R S LAWN MOWERS MOWER DECKS SCM48 SCM54 ...

Page 7: ...7 CHAPTER 1 INTRODUCTION 3 EXTERIOR VIEW AND DIMENSIONS 1935 mm 1965 mm 1100 mm 1265 mm ...

Page 36: ...36 SERVICE MANUAL FOR SGR19 SGR17 Fig 3 55 III 3 CYLINDER BLOCK 1 EXPLODED VIEWS ...