77

CHAPTER 5. HYDROSTATIC TRANSMISSION

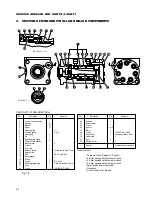

4.9. PRECAUTIONS FOR INSTALLATION OF

HST UNIT

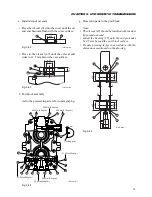

(1) INSTALLATION OF SHAFTS

a. The input shaft (output shaft) and the driving

shaft (driven shaft) of the two shaft type HST

should be aligned correctly. The deviation of

centering should be less than 0.05 mm.

b. When mounting or dismounting the two shaft

type HST onto or from the machine, prevent the

input and output shaft end from excessive thrust

load.

(2) INSTALLATION OF TRUNNION SHAFT

Provide a stopper in place before the maximum

inclination of the trunnion shaft when there is a

fear of application of stronger force to the trun-

nion shaft than HST operating force.

4.10. PRECAUTIONS AFTER INSTALLATION

OF HST UNIT

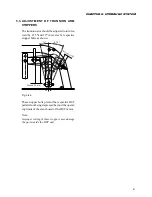

(1) STARTING

a. Fill the HST case with working fluid.

b. After the installation of the HST system, oper-

ate the control lever or pedal slowly several times

in order to bleed the system of air completely.

• When air-bleeding is incomplete, trapped air

bubbles make noise. Repeat the above air-bleed-

ing operation until such noise is elimiated.

• When excessive air is trapped inside the system,

the output shaft may not turn. But when the con-

trol lever is held at the maximum angle under

idling speed for a while, the shaft will begin turn-

ing. This may cause the machine to start abruptly,

so a safety measure should be provided such as

jacking up the drive wheels.

c. At first make sure there are no abnormal noises

or vibrations generated at low speed and then

acceralate to the specified speed.

(2) OIL TEMPERATURE

It is a very important factor at what temperature

a hydraulic system operates. High operating

temperaure will cause working oil to deteriorate

faster, that is, oil is oxidized faster. On the other

hand excessively low operating temperature in-

creases oil viscosity resulting in poor mechani-

cal efficiency of the HST.

Consequently abide by the following items:

a. When starting the machine at 10

°

C or colder tem-

perature, wait until oil temperature becomes

higher than 10

°

C by warm-up operation or us-

ing an oil heater. Then start operation.

b. Normal operating temperature: 20

°

C to 60

°

C

c. Maximum operating temperature

The maximum operating temperature should be

80

°

C. This limit is determined form the viscocity,

oxidation-proof property of working oil and de-

terioration of O-rings and oil seals. Consequently

operation at higher than 80

°

C will shorten the

service life of the HST and working oil.

(3) PERIODICAL INSPECTION AND CHANG-

ING INTERVALS OF WORKING OIL

As the system operates, deposits like sludge ac-

cumulate within circuits and oil tank and work-

ing oil deteriorates, which will prevent the sys-

tem from smooth operation in the end.

Consequently working oil should be checked

periodically to replace it timely with new one.

As it is very difficult to judge how oil has dete-

riorated visually, a rule of thumb is given below.

Normally the oil should be replaced after the

intial 50 hours of operaton and then every year

(before the new season begins) when the ma-

chine is used for less than 250 hours or every

250 hours of operation.

As water and sludge will be deposited in the cir-

cuits and oil tank when replacing the working

oil, the whole system should be flushed clean

before filling it with new oil.

Summary of Contents for SCM49

Page 1: ...S E R V I C E M A N U A L I S E K I L A W N M O W E R S LAWN MOWERS MOWER DECKS SCM48 SCM54 ...

Page 7: ...7 CHAPTER 1 INTRODUCTION 3 EXTERIOR VIEW AND DIMENSIONS 1935 mm 1965 mm 1100 mm 1265 mm ...

Page 36: ...36 SERVICE MANUAL FOR SGR19 SGR17 Fig 3 55 III 3 CYLINDER BLOCK 1 EXPLODED VIEWS ...