TH4330,4290,4260

38

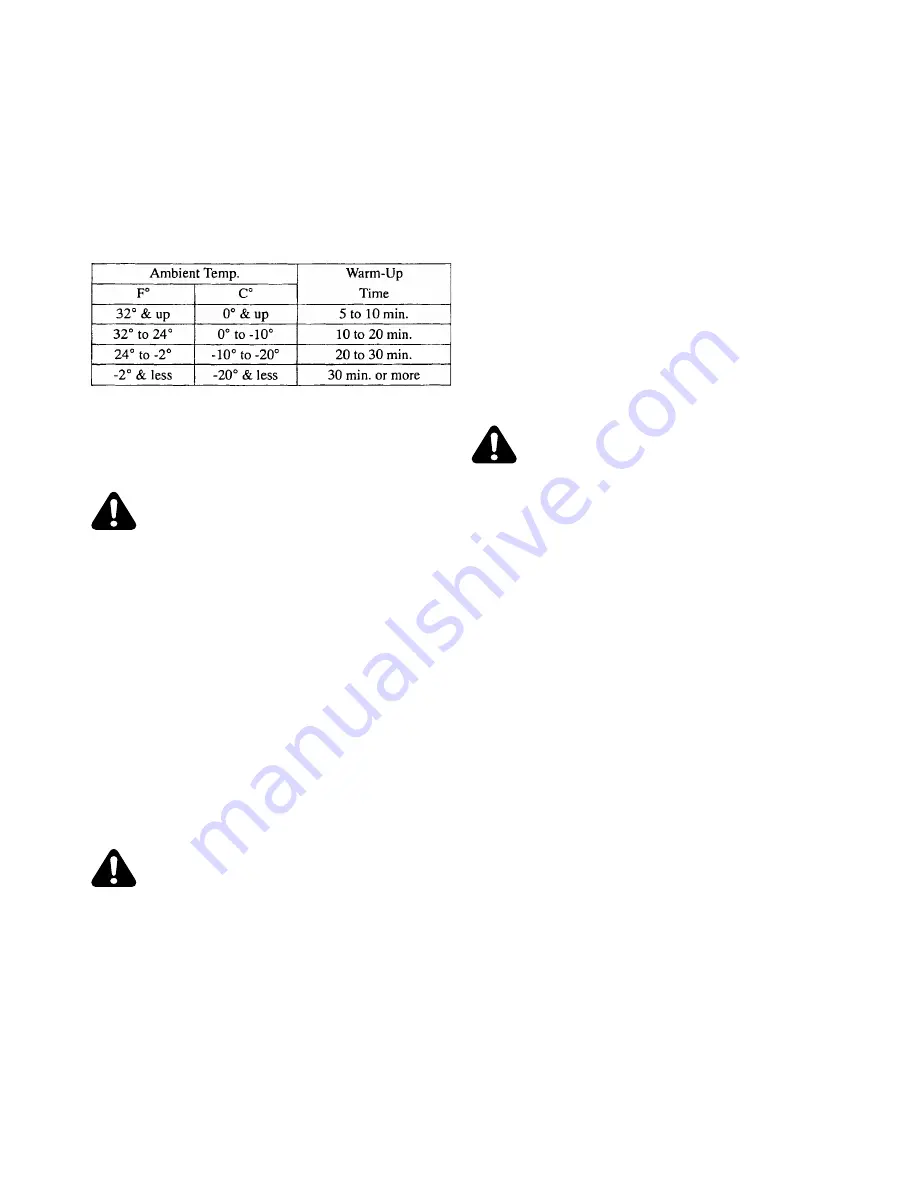

Warm Up Period

After starting a cold engine, let engine idle at slow speed

to make sure all engine components are lubricated.

In colder ambient temperatures, extended warm-up will

be required to also warm hydraulic fluid and lubricate dri-

veline components.

Suggested warm-up period:

IMPORTANT: Improper warm-up can result in severe

engine damage, hydraulic pump seizure,

driveline bearing/gear damage and / or

sluggish steering / breaking.

CAUTION: Make sure parking brake is

securely applied and all controls are in neu-

tral while warming unit. Do not leave unit

unattended.

Operator Observations

Constant attention should be paid to the following points

during operation:

Engine oil pressure lamp will come on in case of low

engine oil pressure. Stop engine immediately. Battery

charge lamp will come on if battery is not being charged

properly. Stop engine and investigate cause.

Coolant temperature gauge needle will indicate H (hot) in

case of overheated engine. Stop engine, allow to cool

and investigate cause.

Fuel gauge should not be allowed to E (empty) as run-

ning out of fuel may result with need to bleed air from fuel

system.

CAUTION: DO NOT attempt to service Tractor

with engine running or hot. Allow to cool.

NOTE: Refer to "Troubleshooting" when defect is indi

cated, to assist locating problem.

Starting Circuit Operation

Tractor is equipped with a starting system to protect the

operator. To permit tractor to be started (start motor to

operate), ALL the following is required:

(Mechanical Transmission)

Gear and Range shift lever in Neutral.

Rear and Mid PTO shift lever in Neutral.

Depress clutch pedal.

(Hydrostatic Transmission)

Range Gear Shift Lever in Neutral

PTO control switch in OFF position.

In addition, the operator must be seated in the operator’s

seat. If the operator leaves the seat with; range shift lever

in gear, PTO switch ON, the fuel shut-off mechanism will

be activated and the engine will be stopped.

WARNING: Neutral switch system is installed

for your protection. DO NOT bypass or modi-

fy the neutral start switch system. If the neu-

tral start switch system does not operate

properly as detailed above, contact your

Dealer immediately and have the system

repaired.

Periodically check that the starting circuit is functioning

correctly. The procedure for this is check is as follows:

1. Check that there are no bystanders around the tractor

should it inadvertently start.

2. Depress the clutch and brake pedal. Attempt to start

the tractor with the gear and range shift levers in neu-

tral and PTO control switch OFF. The tractor should

start.

3. Depress the brake pedal. Attempt to start the Tractor

with the gears engaged and the PTO in ON position.

The Tractor should NOT start.

If starting system is not working correctly it must be

repaired immediately by your Dealer.

Summary of Contents for TH4260

Page 72: ...TH4330 4290 4260 72 FIG 6 34 3 FIG 6 34 4 ...

Page 91: ...ISEKI TRACTOR 91 ...

Page 92: ...TH4330 4290 4260 92 ...

Page 93: ...WIRING DIAGRAM WIRING DIAGRAM WIRING DIAGRAM TH4260F ...

Page 94: ...WIRING DIAGRAM TH4260FH ...

Page 95: ...WIRING DIAGRAM TH4290F ...

Page 96: ...TH4330 4290 4260 WIRING DIAGRAM TH4290FH 4330FH ...