44

TXG23

Using Position Control (4WD model)

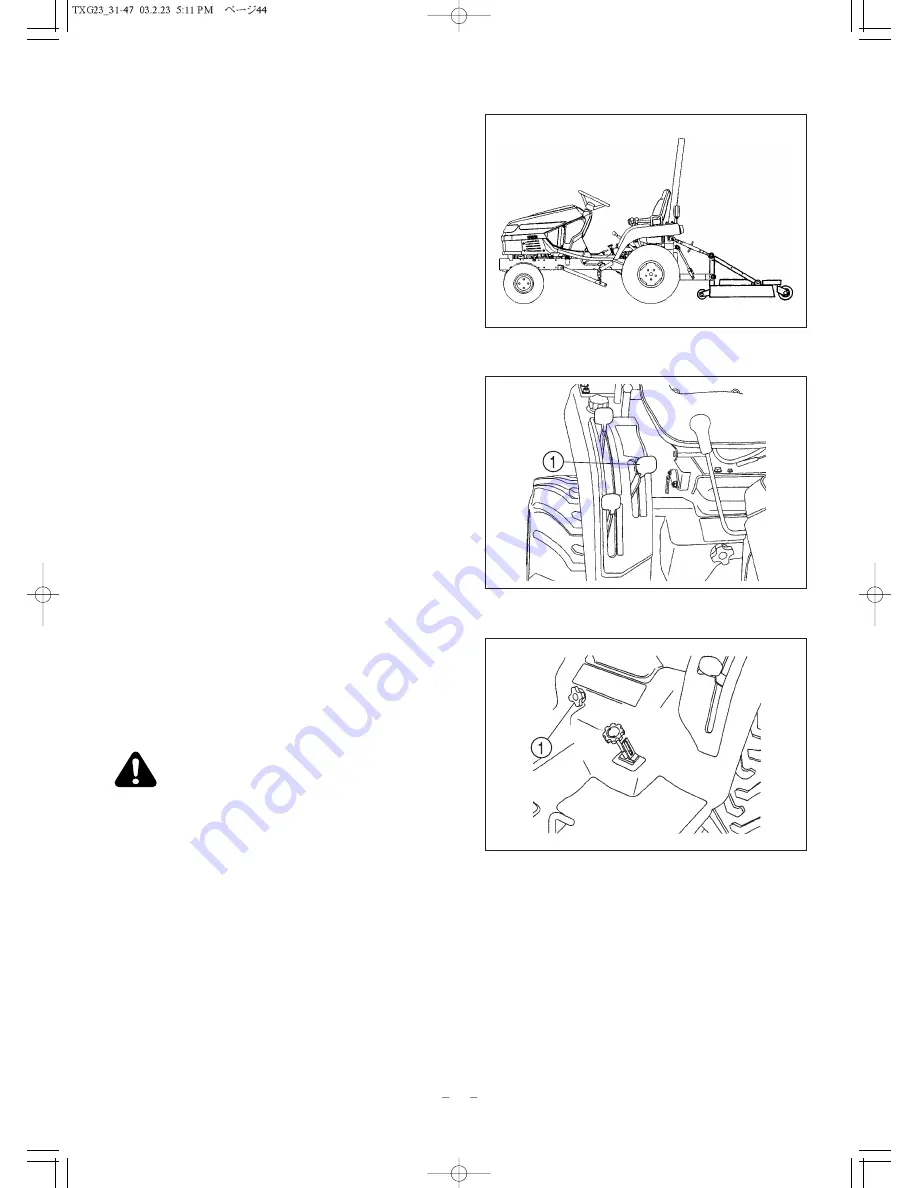

FIG. 48: Type of Work - Attaching/detaching implements

and other operations requiring implement to be kept at

constant height above ground. Also used with implements

equipped with gauge (support) wheels.

FIG. 49: Lever Positions - Use position control lever, 1,

to adjust hitch and implement position.

To Begin Work - Align Tractor and implement in field and

move position control lever, 1, forward (toward DOWN).

Adjust implement height using position control lever as

desired. Note location of lever.

When Turning - Move position lever, 1, rearward (toward

UP) to raise implement. Finish turning and return lever to

previously set position to resume operation.

To Finish Work and Transport - Move position control

lever, 1, fully rearward in quadrant.

Fig. 50: When using different weights of implements,

"rate of drop" of three point linkage and implement can be

controlled with the "Lowering Rate Control" Knob, 1.

Turn knob clock wise to slow drop rate, counterclockwise

to increase drop rate. Turning knob fully clockwise will

lock implement in raised position.

CAUTION: When using mounted implements

with the PTO driveline, make sure:

PTO drive shaft has minimum 51mm(2")

engagement of telescoping sections, at all

hitch/implement positions.

Hitch height during raising does not bind

drive shaft universal joints due to extreme

drive shaft length,

PTO drive is disengaged during transport.

FIG. 48

FIG. 49

FIG. 50