16

-

20

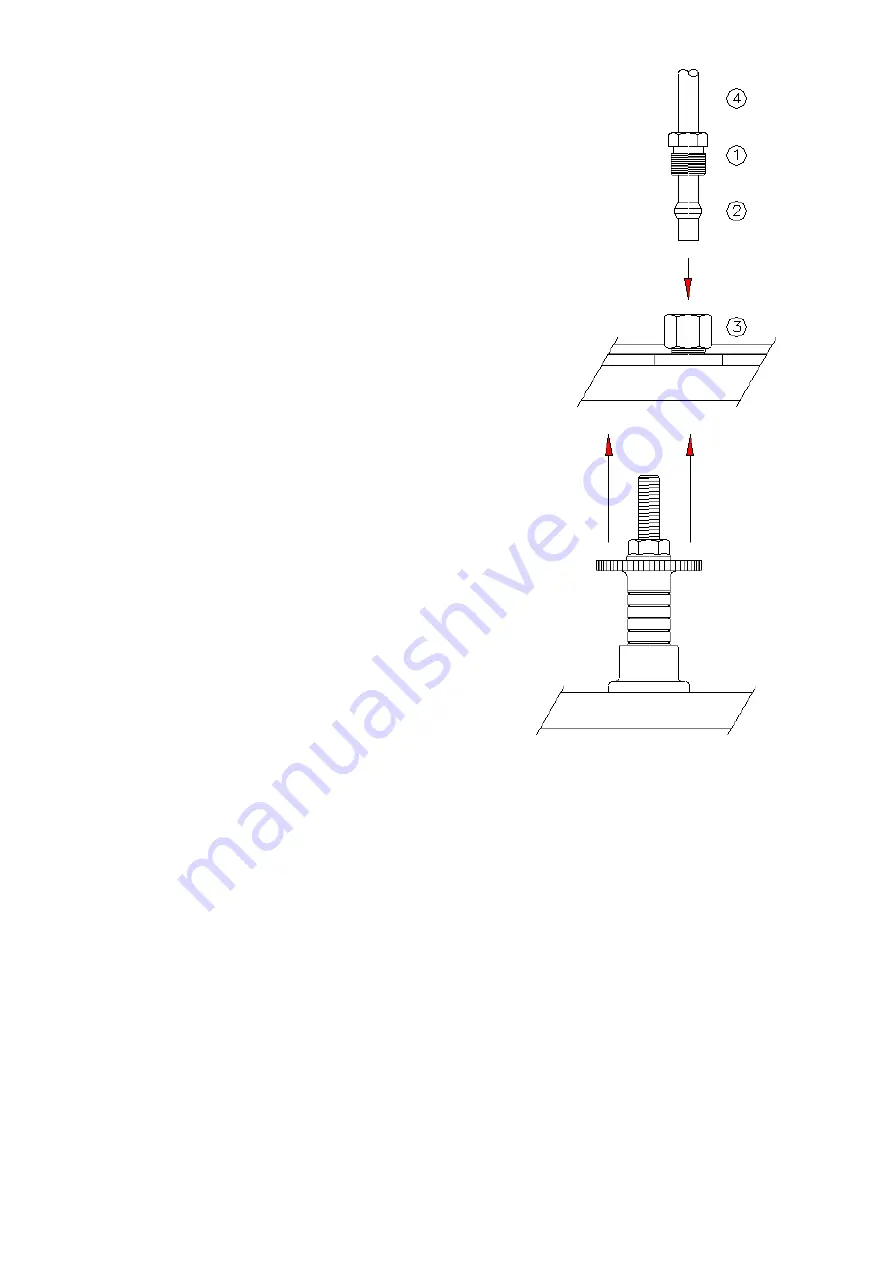

2-4.3 Lubrication line connection

(See Fig. 4)

Solderless tube connection (double

tapered sleeves) can be used. The tube must go through

compressed bushing (1) and double tapered sleeve (2).

To avoid any leaking during running service time, it

should be observed up to 1mmdistance between the tube

end to the double sleeve. Insert tube end into

counterbored port (3) up to the stop. First tighten

compressed bushing finger-tight by hand. Then turn

another 1

1

/

2

turns.

Fig. 4

2-4.4

Manual pump

Pull the regulating plate to the top and let it return

to the original place. In this process, the lubricant is

conveyed to the lubrication line.

Warning!

Don’t press the regulating plate

back. The regulating plate must return by

spring-loaded force.

Fig. 5

2-4.5

Wiring and alarm

Warning !!

To prevent chance of serious injury, death or property damage,

disconnect the product from main power supply before working on it.

The electrical circuit diagram of the lubrication unit is affixed inside the unit and can

be accessed by removing the cap.

Remove the cap (Fig.6) and inside you can see terminal plate and cable gland nut.

Loosen cable gland and then insert cable through the cable gland hole (Fig. 7) to wire

up(Fig. 8). Fix the cable gland to the housing.

Wiring must comply with the electrical circuit diagram (Fig.8) of the lubrication unit

affixed inside the unit.

Otherwise, property damage or serious injury can occur.

Install a fuse between the power supply and the product to protect the lubrication unit

is strongly recommended! Current of fuse, max : 220V 0.3A ; 110V 0.1A