Chapter 3 TEST MODE

3-10

IL-2000SA Service Manual

¡

Label Sensor Level

1.

Label sensor (transmission sensor) mechanism

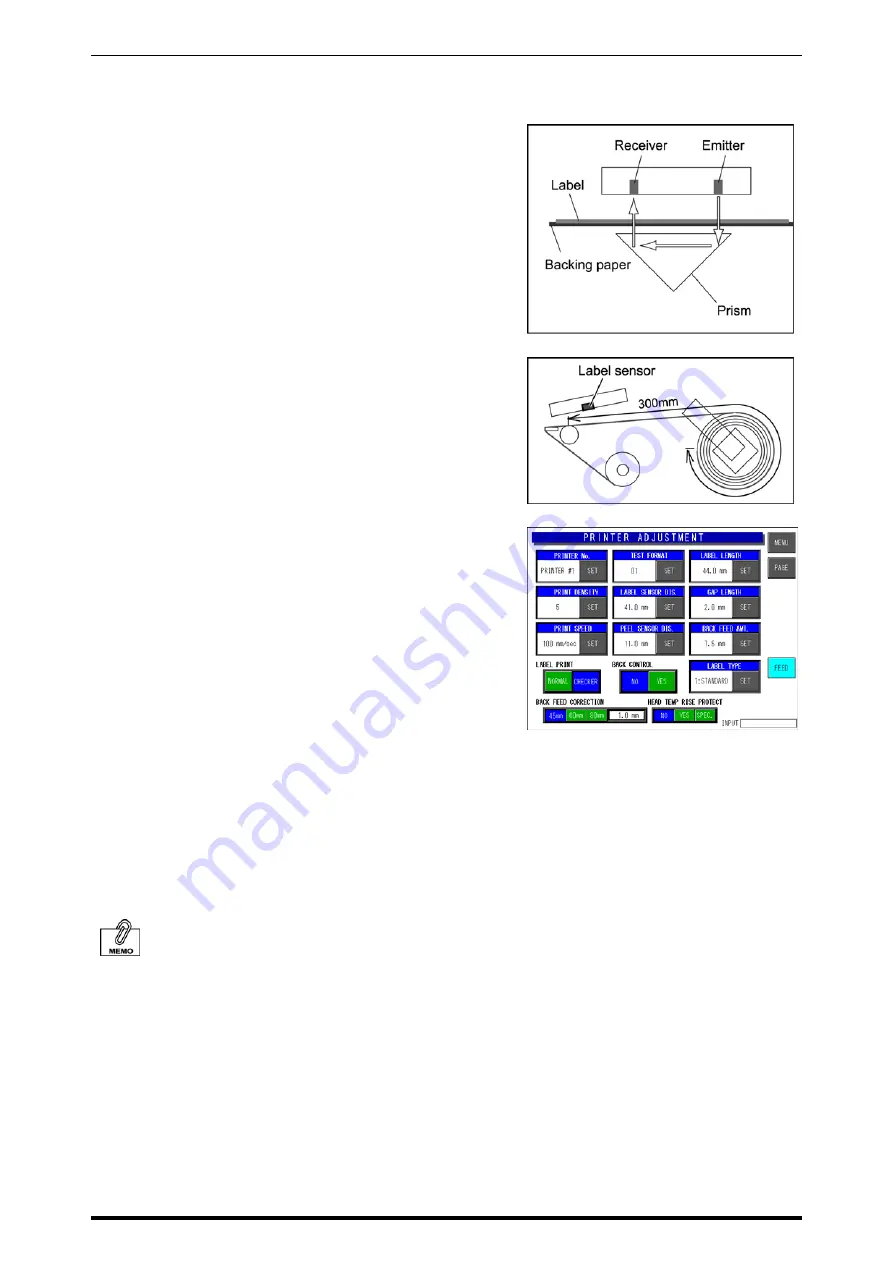

The label sensor has a mechanism as shown in the

right figure.

The light emitted from the emitter

Passing the label and reflects the light in 90

degrees

→

90 degrees (180 degrees) with the prism.

The reflected light passes the label again, and receives

the light at the receiver.

2.

Adjustment of the label sensor

(1) Peel off approximately 10 labels (approx. 30 cm) so

that the label sensor can detect the label backing

paper only, and insert the cassette. Do not care

even if you rewind the paper when it is already

wound up.

(2) Touch the [FEED] key twice to stretch the backing

paper.

(3) The data field changes to green when the [LABEL

SENSOR LEVEL] button is touched.

(4) Touch

[▲][▼]

keys to make the numeric value

around “120”. This value is assumed as (Numeric

value A).

(5) Touch the [FEED] key several times again to issue

one label. At this time, the label sensor is detecting

the label and the backing paper. This value is

assumed as (Numeric value B).

(6) When the result of (Numeric value A) - (Numeric

value B) is “60” or more, the adjustment is

completed.

(Numeric value A) - (Numeric value B)

≥

60

If the result is less than “60”, try to adjust from (1)

again. Use the numeric value with (+10) added to

the previous case.

This machine does not have the VR (volume) for the sensibility adjustment

.

The label sensor sensibility adjustment of the conventional model has been made by the VR

(volume). However, software adjustment can be performed by adopting the DPM (digital

potentiometer) with this machine. Therefore, the VR (volume) adjustment by is unnecessary.

DISCONTINUED

Summary of Contents for IL-2000SA

Page 10: ...D I S C O N T I N U E D ...

Page 32: ...D I S C O N T I N U E D ...

Page 76: ...D I S C O N T I N U E D ...