10

IWQ Operation Manual Kg Version

Manual No. 0142A

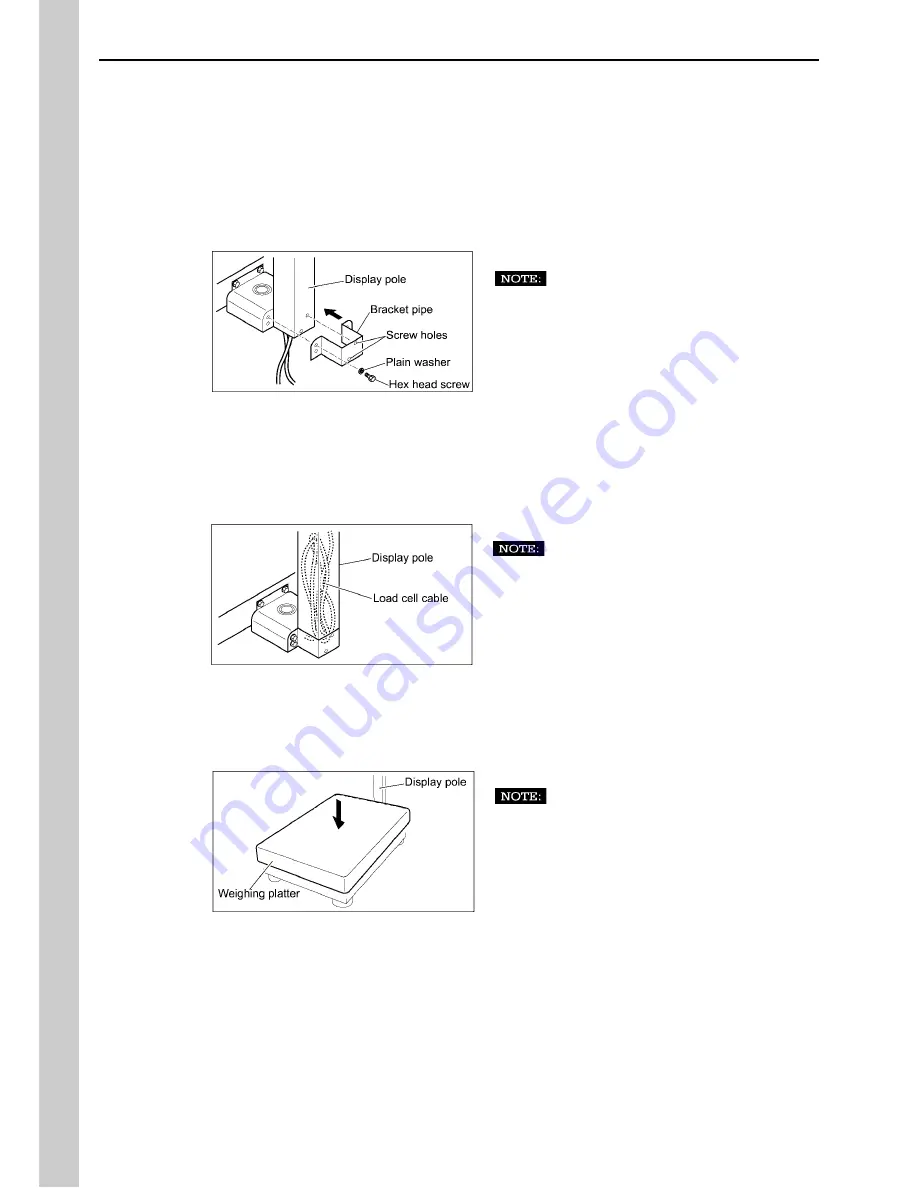

4. Fix the Display Pole with the Bracket Pipe.

After confirming the screw holes are aligned, fix the display pole to the scale body with the

bracket pipe (at four points with plain washers and hex head screws).

Fit the bracket pipe with its larger radius cor-

ners facing upward. Securely tighten the

screws until the display pole becomes steady.

5. Store the Load Cell Cable inside the Display Pole.

Fold up the extra length of load cell cable and store it inside the display pole.

Push the load cell cable deeply into the dis-

play pole at least 15 mm away from the pole

end.

6. Install the Weighing Platter.

Make sure that nothing has been placed on the

weighing platter.

Summary of Contents for iwq-150/30

Page 34: ...2001 Aug ...