Manual No. 0149A

IWQ Operation Manual Kg Version

29

9. Routing Servicing and Cleaning

9-1 Routine Servicing

After cleaning the outer surface of the scale with a soft wet cloth, wipe it with a dry cloth.

9-2 Cleaning Methods

To ensure your personal safety, disconnect the electrical plug from the outlet before any

servicing or cleaning.

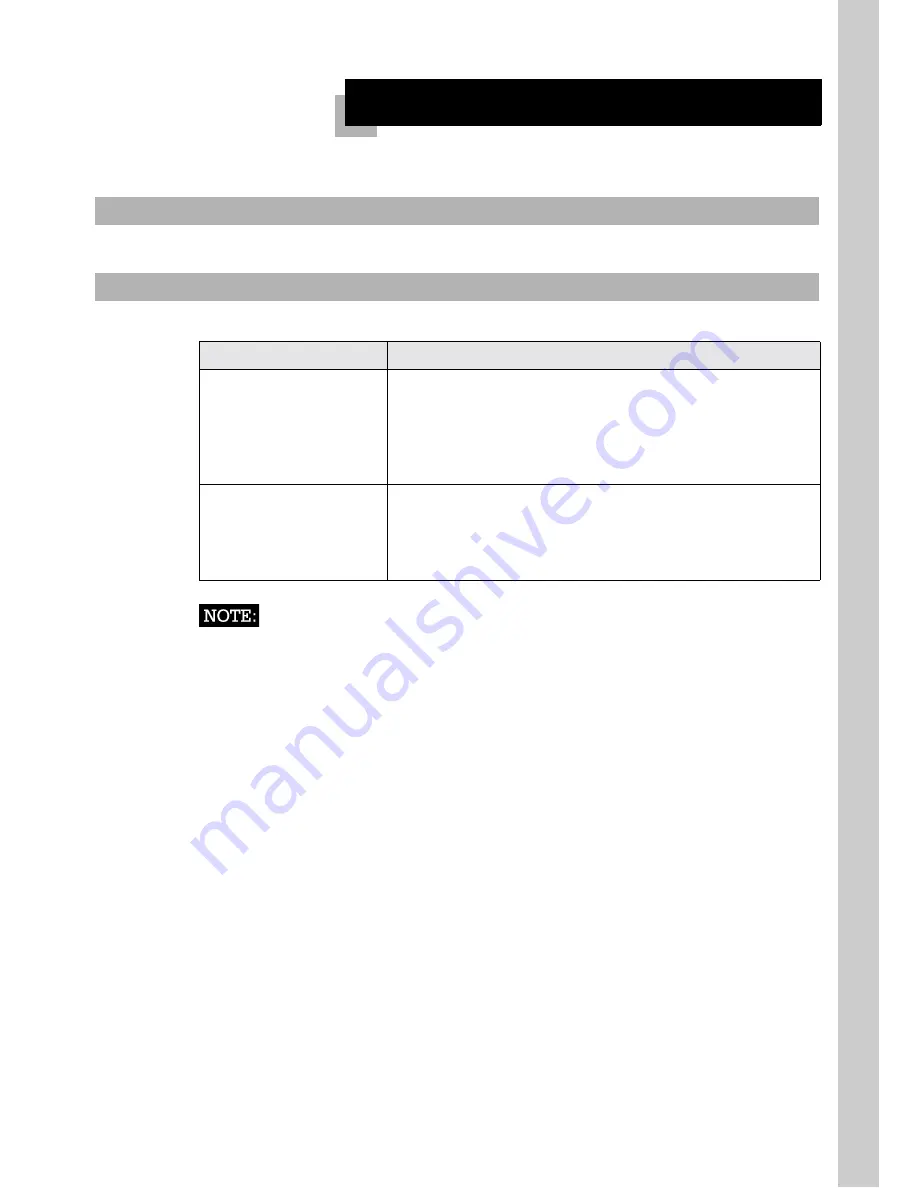

Part to be cleaned

Cleaning method

Weighing platter

(1) Remove the weighing platter from the scale, and rub the platter sur-

face gently with a soft brush or soft cloth soaked with water-diluted

neutral detergent. Then wash the platter in water and dry.

(2) Remove the weighing platter from the scale, dip it in hot water (70 to

90

℃

) for about 30 minutes, and then dry.

• Be careful not to get scalded.

Weighing unit, display pole,

and display unit (parts other

than the weighing platter)

Wash the outer surface in water (normal temperature), and then dry.

• Do not use a detergent or chemicals other than those mentioned

above.

• Do not allow a brush, solid, or any rough material come in contact

with the weighing unit after removing the weighing platter.