1.

Install Load Limiter device

to the non

-

moving rope/

chain near to the anchor/suspension point on a

slacked (non

-

loaded) hoist.

2.

Torque rope clamps down

. Cotter pins are simply to

keep the unit in place.

3.

For preset units

see

“

sizing overload limit devices

”.

4.

The normally closed contact wires should be

placed in series

with an appropriate part of the hoist

circuitry usually the contactor coil of the UP contactor.

As the load increases the switch will open at the ap-

proximate setting and shut down the movement of the

hoist in the UP direction. Slack Load option is put in

the DOWN circuit of the hoist.

5.

Hysteresis:

All electro

-

mechanical devices exhibit

hysteresis such that to RESET it is likely that the

load must decrease below the

“

trip point

”

in order

to reset.

6.

Repair

of any Load Limit device should not be at-

tempted except for superficial problems such as a cut

wire etc. NEVER disassemble and reassemble any

unit. The

“

link

”

pins on the Chain Load Limit devices

are of special grade steel and should never be modi-

fied or replaced with other than factory supplied parts.

Installation of Load Limiters

485 Dundee Avenue, Suite 85

East Dundee, IL 60118, USA

Phone: 847-836-8844

Fax:847-428-9379

INDUSTRY SOLUTIONS

I N T E R N A T I O N A L, I N C.

561 Plate Drive, #5

East Dundee, IL 60118, USA

Phone: 847

-

836

-

8844

Fax: 847

-

428

-

9379

Model

* Best Torque

Socket

LL18, LL28

8 Nm or 5.9 Ft. Lbs.

13mm

LL45, LL60

10 Nm or 7.4 Ft. Lbs.

16mm

LL80, LL150, LL200

15 Nm or 11.1 Ft. Lbs.

19mm

table 3

Rope Clamp Bolt Torque Rating

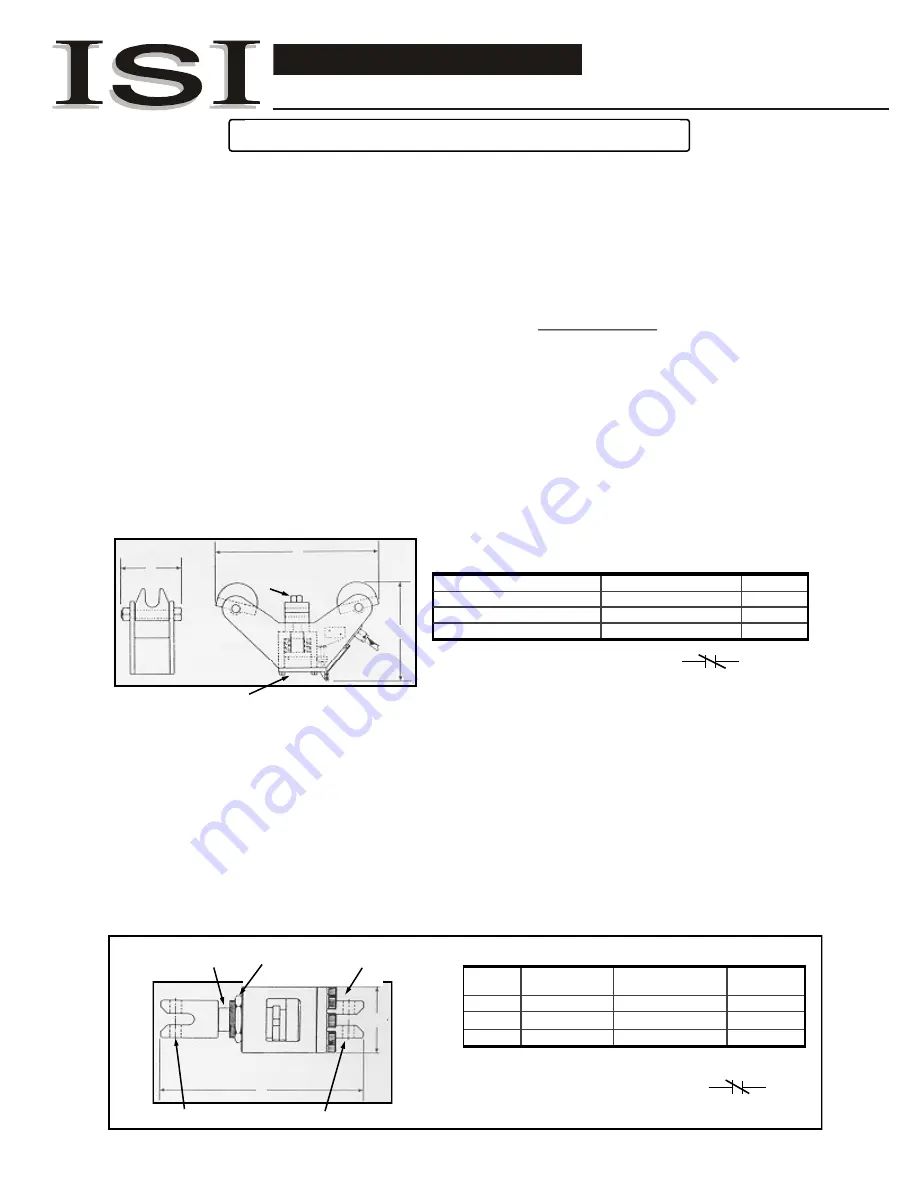

fig. 3b Wire rope Hoist Load Limit-

er showing internal mechanics,

rope clamp and cover plate for

adjusting screw.

WIRE ROPE STYLE

C

B

A

Protective cover plate for adjustment screw.

WIRE ROPE STYLE

-

Setting in the field:

a.

Detach the back protection plate.

b.

Pick up the heaviest load required ensuring that it is not more than the safe working load of the crane &

hoist combination.

c.

Turn the adjusting screw (under protective cover plate) out fully, pick up safe working load, turn adjusting

screw in until cut out then turn back about 1/8 turn and lock. The adjusting screw is very sensitive.

d.

Lower the load and lift up again to ensure correct functioning. Do this several times as a check. You may

have to fine tune several times.

* USE TORQUE WRENCH to put cable clamp on hoist!

e.

Reattach back protective plate.

(see

* Best Torque below)

Model

Link Pins

Allen Hex

Adjusting Collar

Lock Nut

LL12C

6mm 13mm

19mm

38mm

LL17C

10mm 19mm

25mm

50mm

LL28C

10mm 19mm

25mm

50mm

table 4 Chain Link Pin, Adjusting Collar and Lock Nut sizes

fig. 4b

Chain hoist load limiter showing adjustment

collar lock nut and link pin placement (included).

CHAIN STYLE

LOCK NUT –do not adjust

all the way out.

ADJUSTING COLLAR

B

A

LINK PIN PLACEMENT—

-

ONLY USE ISI SUPPLED !!!!

CHAIN HOIST STYLE

–

Setting in the field:

a.

Install Chain Load Limiter device using Link pins provided, see table 4.

b.

Use the heaviest load required ensuring that it is not more than the safe working load of the crane and hoist

combination.

c.

LOOSEN LOCK NUT. Turn the adjusting nut IN (clockwise) to increase the chain load setting and or OUT

(counter

-

clockwise) to decrease the setting (see

fig 4b

). The adjusting nut is very sensitive and a small adjust-

ment will cause a relatively large change in setting. The adjusting nut is tight and is constantly under internal

pressure.

d.

When desired cut out point is reached, the N.C. contact will open (test several times to assure setting), the

adjusting nut must be locked by tightening the lock nut (

see fig 4b

).

e.

CHECK load cut out again to ensure proper setting. You may have to fine tune.

f.

Ensure that any hoist

“

top

”

limit switches are set and arranged so the Chain load limit device could not be

broken by the bottom block when at maximum lift height.

Clamp bolt

fig. 3b

fig. 4b

© 201

9

Industry Solutions International, Inc.

Prices and specifications are subject to change without notice.

N.C. Circuit

N.C. Circuit

1

201

9

060

3

B