8

®

OPERATING INSTRUCTIONS

BAFFLE AND FLUE CLEANING

It is important that the throat plate and all the stove flue are kept

clean. They should be checked approximately once a week, by

looking up into the firebox for signs of soot or fly-ash on the baffle

and at the sides of the firebox. If there are signs of a build up of soot

or fly-ash deposits then the fire must be let out in order to clean the

throat plate and flue.

Before attempting to clean the baffle and flue, ensure that the fire is

cold. Wear suitable gloves to prevent irritation from soot deposits.

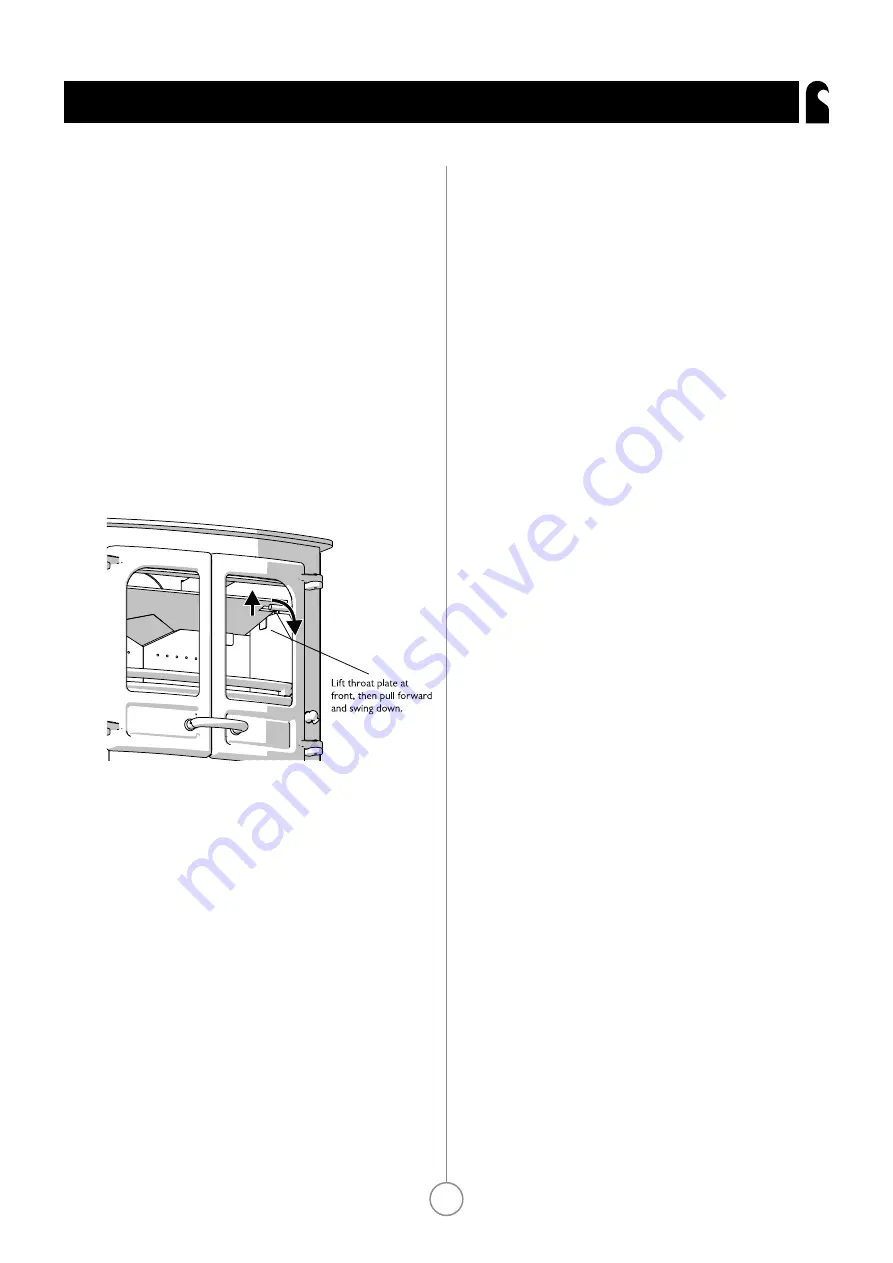

To remove the throat plate lift the front edge up and slide the plate

forward until it comes clear of the front pegs, then swing the front

edge down (see Fig. 8).

Fig. 8. Baffle

FLUE SWEEPING

When installing your Charnwood into an existing brick flue that has

previously served as an open fire, it is possible that the higher flue

gas temperature from a stove may loosen soot deposits with the

consequent risk of flue blockage. It is therefore recommended that

the flue be swept a second time within a month of regular use after

installation.

Your Charnwood flue should be swept at least twice a year. Where

the top outlet or vertical rear flue connector is used it will generally

be possible to sweep the flue through the appliance.

First remove the upper and lower baffles. Then sweep the flue

ensuring that soot is removed from all horizontal surfaces after

sweeping.

In situations where it is not possible to sweep through the appliance

the installer will have provided alternative means, such as a flue

access door.

After clearing any soot from within the stove, replace the baffle (see

Fig. 8 ).

It is important to use the correct flue brush for the flue size, different

types of sweep’s brushes are available to suit different flue.

For prefabricated insulated flues the manufacturers instructions with

regard to sweeping should be consulted.

TROUBLE SHOOTING

Fire Will Not Burn

Check that:

a) the air inlet is not obstructed in any way,

b) flues and flue are clear,

c) a suitable fuel is being used,

d) there is an adequate air supply into the room,

e) If an extractor fan is fitted, that it is not causing lack of flue draft

when operating.

f) there is sufficient draw in the flue. Once the flue is warm a draught

reading of at least 1.25 mm (0.05 in.) water gauge (12Pa) should be

obtained.

Blackening of Door Glass

Differences in flue draughts mean that the best settings of the air

controls will vary for different installations. A certain amount of

experimentation may be required, however the following points

should be noted and with a little care should enable the glass to be

kept clean in most situations:

a) Wet or unseasoned wood, or logs overhanging the front fence will

cause the glass to blacken.

b) The airwash relies on a supply of heated air to keep the glass clean,

therefore, when lighting the stove allow the firebed to become well

established before closing the air control. This may also be necessary

when re-fuelling the stove.

c) When re-fuelling keep the fuel as far back from the front fence as

possible, do not try to fit too much fuel into the firebox

d) Do not completely close the air control.

It is always more difficult to keep the glass clean when running the

stove very slowly for long periods.

Summary of Contents for III BLU

Page 1: ... Operating Installation Instructions AUSTRALIA III BLU ...

Page 2: ......

Page 21: ...21 ISLAND III BLU DIMENSIONS ...

Page 24: ...your premier dealer ...