KEMPER MaxiFil stationary - operating instructions-

EN

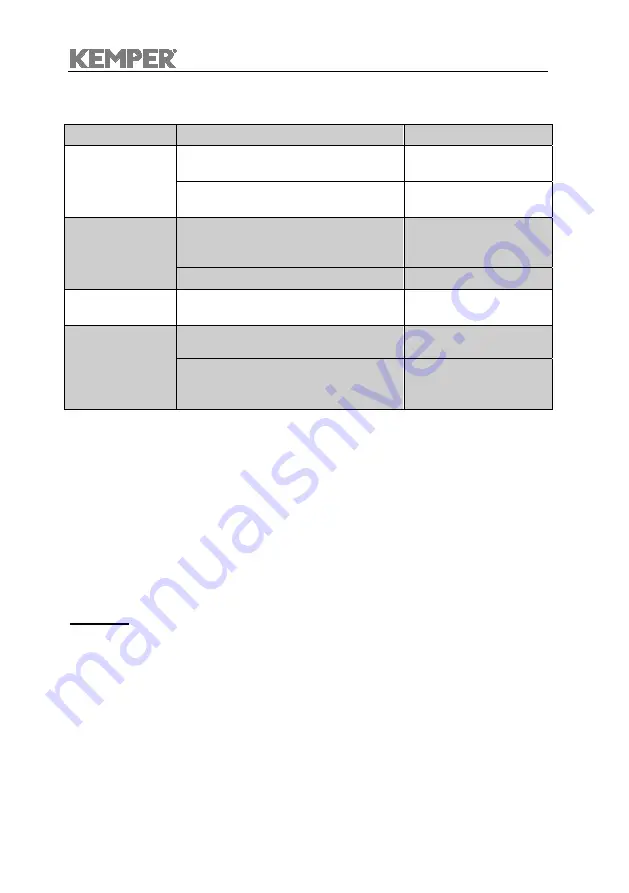

7.4 Troubleshooting

7.5 Emergency measures

The following measures may be helpful in the event of a fire in the MaxiFil:

-

Inform the responsible fire safety officer and follow their instructions.

-

If necessary, Inform the local fire brigade.

-

If possible, disconnect the MaxiFil from the mains by pulling the plug or have

an instructed specialist (electrician etc.) disconnect the electrical power supply

for the MaxiFil at the upstream local sub-distributor.

-

If necessary, Fight fire with commercially available dry powder extinguisher.

Attention!

Flash flame formation, hazardous fumes and smoke occur in the event of a fire which

may lead to suffocation. If possible, wear personal protective equipment.

Fault

Possible cause

Solution

Not all fumes are

captured.

Distance of extraction hood to welding

site too large.

Move extraction hood

closer.

Blow-off covered up.

Keep blow-off

uncovered.

Signal horn

sounds

Extraction performance too low,

throttle valve in the extraction hood

closed.

Open throttle valve in

extraction hood fully.

Filter element saturated.

Change filter element.

Dust comes out

on clean air side.

Filter element is damaged.

Change filter element.

Device does not

start.

Lack of voltage.

Have it checked by an

electrician.

Start-stop sensor connected, however,

no power detected (no welding

happening yet)

Start welding process

- 85 –

Technical modifications and errors expected.

Summary of Contents for Kemper MaxiFil

Page 2: ......

Page 338: ...KEMPER MaxiFil stacionární Návod k použití CZ 338 7HFKQLFNp PČQ D RP O Y KUD HQ ...

Page 509: ......

Page 510: ......

Page 511: ......