Whether a flush hearth is preferred or a raised

hearth, the combustible floor on front of the fireplace must

be covered with a noncombustible hearth extension set

tight against the fireplace front and extending at least 20

inches out from the finished fireplace and at least 12 inches

beyond the finished sides of the fireplace opening.

For all “raised hearth” construction where

concrete blocks are used to create the raised platform,be

sure to mortar the concrete block platform together. CMU

used for base plate support should be rated ASTM 90.

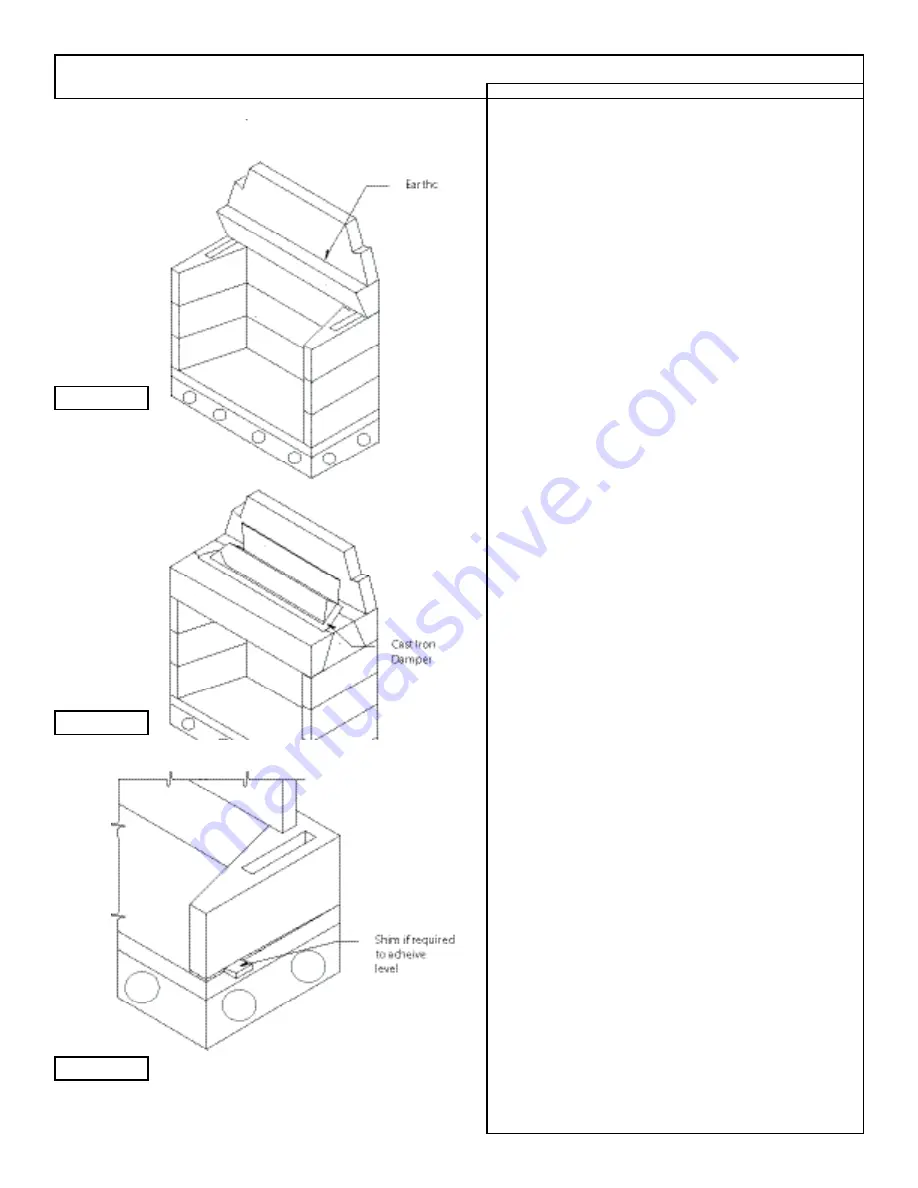

Step 2:

Set the firebox base plate with mortar so that the

front, rear and side walls are all flush with the front, rear

and sides of the Fire-Lite base. Mortar to the base with

Eartcore mortar. For seismic anchorage, please call the

technical department at: 800-642-2920.

Step 3:

Set the first course of the firebox back wall and

side walls into place.

It may be convenient to dry set the first course

of side wall and back wall into place on the Isokern base

plate and then to trace their position on the base plate with

a pencil.

After outlining the dry set pieces, remove them

and apply Earthcore Mortar to the areas traced on the base

plate where the side walls and back wall are to sit. By doing

this, the first layer of wall components can be set directly

into mortar already applied to the proper areas on the base

plate.

Be sure to put Earthcore Mortar on the contact

surfaces of the vertical joints where the side wall and back

wall components connect. (Figure 15)

Broken Components:

Components broken into 2 or 3

pieces can be repaired by using Earthcore Mortar along the

break line as the component is set into place. Components

broken into multiple small pieces should be discarded and

replaced.

Leveling And Aligning Components:

Be sure to assemble

all Fire-Lite components level and flush with adjoining

components.

Leveling and alignment adjustments are made by

the use of small plastic shims (supplied with the unit). The

shims can be inserted under a component to level and align

it with adjacent Standard components (Figure 16). Be sure

to re-grout any and all gaps resulting from shim insertion.

Notes:

A. Do not mix Earthcore Mortar with spirits or antifreeze

agents.

B. The maximum recommended mortar joint thickness at

Isokern components is one-quarter inch (1/4”).

C. Earthcore Mortar can be troweled over the face of a joint

where it has squeezed out while setting components.

It is not intended that the exposed faces of the Standard

components be completely covered with the mortar.

13

Assembly Instructions - (cont.)

FIGURE 14

FIGURE 15

FIGURE 16

Summary of Contents for FIRE-LITE series

Page 7: ...Assembled Firebox Smoke Dome Dimensions 36 42 46 7 ...

Page 23: ...23 Interior Masonry Veneer Fireplace Finishes Clearances FIGURE 38 FIGURE 36 FIGURE 37 ...

Page 28: ...DM 54 Chimney Component List Dimensions 28 ...

Page 32: ...32 DM 54 Chimney System Lateral Support cont FIGURE 51 FIGURE 52 ...

Page 51: ...51 Fire Lite Application Raised Metal Platform cont FIGURE 93 ...

Page 58: ...Notes 58 ...