26

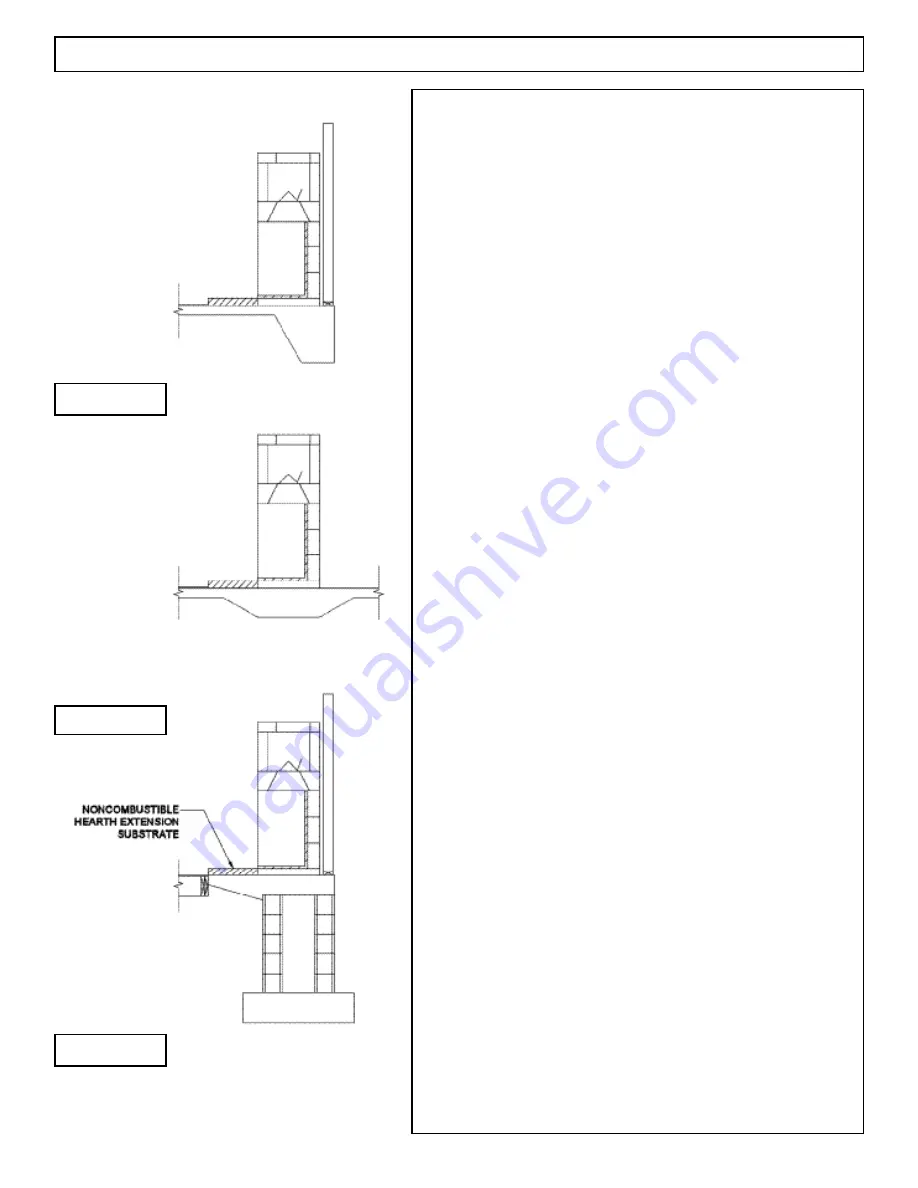

FIGURE 43

FIGURE 44

FIGURE 45

The Fire-Lite fireplace is not rated for installation on a combus

-

tible floor system unless used in the Fire-Lite application

(see Pages 47-55). Fire-Lite fireplaces must be built upon a concrete

support slab with no wood underpinnings. Proper reinforced concrete

support slab for Fire-Lite installations may include the following types:

1. Slab on grade: Fire-Lite residential, minimum four inch (4”) thick,

2500 psi concrete foundations on properly compacted fill. This type

foundation can support Isokern installations up to thirty feet (30’) overall

height (brickledge installations not included). (Figure 43)

2. Slab-on-grade foundations, thickened and reinforced: for additional

load carrying. (Figure 44)

3. Off-grade slab on foundation walls and footings.

Projects with off-grade floor systems as well as upper story

installations require this type of support. (Figure 45)

When building off-grade support slabs the code required hearth

extension substrate should be built as a continuation of the support slab

for the Fire-Lite unit. (Figure 45)

Supports for off grade slabs must be concrete or steel and ca-

pable of supporting the slab, Isokern unit and the chimney.

For multi-floor and back-to-back installations proper

weight computation on an individual basis is required. Consult local

structural engineer for load bearing requirements.

Important:

Foundations and footings must meet local code and be

approved by the local building authority. For any foundation design and

load requirements check with local structural engineer. It is the responsi

-

bility of the General contractor to insure adequate foundations.

Fire-Lite fireplace weights and “foot print” areas:

The total fireplace weight for each Fire-Lite model

listed below includes: Fire-Lite unit pumice parts only:

A. Model Fire-Lite 36: 1205 lbs.

B. Model Fire-Lite 42: 1324 lbs.

C. Model Fire-Lite 46: 1450 lbs.

Totals are exclusive of any chimney components.

See page 29 for Isokern DM chimney component weights.

The “footprint” area for each model is as follows:

A. Model Fire-Lite 36 @ 43” x 25 1/4” = 7.54 sq. ft.

B. Model Fire-Lite 42 @ 49” x 25 1/4” = 8.59 sq. ft.

C. Model Fire-Lite 48 @ 53” x 25 1/4” = 9.30 sq. ft.

“Footprint” areas listed above are base plate dimensions for

each model and are exclusive of code required hearth extension areas.

See page 25 for hearth extension dimensions.

Note:

Additional support slab area may be required at the side or back of

the Fire-Lite unit to provide bearing for structural supports to a

DM 54 offset chimney sequence.

(See pages 33-36 for offset chimney support requirements.)

Concrete Support

Summary of Contents for FIRE-LITE series

Page 7: ...Assembled Firebox Smoke Dome Dimensions 36 42 46 7 ...

Page 23: ...23 Interior Masonry Veneer Fireplace Finishes Clearances FIGURE 38 FIGURE 36 FIGURE 37 ...

Page 28: ...DM 54 Chimney Component List Dimensions 28 ...

Page 32: ...32 DM 54 Chimney System Lateral Support cont FIGURE 51 FIGURE 52 ...

Page 51: ...51 Fire Lite Application Raised Metal Platform cont FIGURE 93 ...

Page 58: ...Notes 58 ...