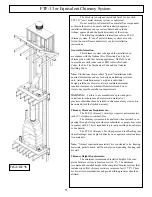

DM 54 Chimney System: Load Capacity - Brick Ledge

38

It is relatively simple to calculate the total physical

load on the brickledge resulting from the physical weight of

applied veneers built to code height, however, calculation val

-

ues for load to the brickledge due to wind are site specific and

based on local variables such as wind speed zone, exposure

classification, eave height and roof pitch of the structure, as

well as height of chimney mass exposed to wind.

Important:

The total load delivered into the brickledge is job

specific and will be the sum of:

(1) the physical load from veneers, plus

(2) the load due to wind.

The total of physical load and load due to wind

must not exceed ninety four hundred (9400) pounds.

Notes:

Calculation of wind load requires the services of a

local structural engineer who can evaluate wind load for the

specific structure and site in question.

Do not subject the brickledge to unequal loading

when applying veneers. Build veneers equally on all four sides

of the brickledge.

Brickledge Veneer Finish and Flashing Details:

When applying brick, stone or other masonry veneer

to the Isokern brickledge Fire-Lite good building practices for

masonry veneer work should govern weather-proofing details

and the placement of flashings.

A typical flashing detail would be to field fabricate an

aluminum or galvanized sheet metal flashing, approximately

thirty-two inches (32”)square with a twenty inch (20”) square

hole in it, to serve as an inner flashing. (Figure 65)

Place the inner flashing on the first DM 54 outer cas

-

ing block that fully clears the roof line. Keep the flashing to

about a one-half inch (1/2”) lap onto the top of the outer casing

block. The twenty inch (20”) square hole in the flashing should

fit to the outside of the alignment grooves on top of the DM 54

outer casing. Continue the DM 54 chimney up to the required

termination height.

Once the masonry veneer is in progress the inner

flashing is set into a horizontal joint in the veneer at a level

above all other roof deck flashings, chimney-to-roof flashings

and counter flashings. Weep holes should open to the outer

face of the veneer at vertical mortar joints located at the level

of the inner flashing. (Figure 66)

Where moisture may develop between the DM

54 outer casing and the chimney veneer, inner flashings as

described above will help to divert such moisture to exterior

face of the veneer by way of the weep holes and thereby keep

such moisture from working its way down between the veneer

facing and the DM 54 outer casing and into the interior of the

structure below.

FIGURE 66

FIGURE 65

Summary of Contents for FIRE-LITE series

Page 7: ...Assembled Firebox Smoke Dome Dimensions 36 42 46 7 ...

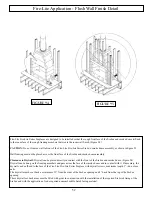

Page 23: ...23 Interior Masonry Veneer Fireplace Finishes Clearances FIGURE 38 FIGURE 36 FIGURE 37 ...

Page 28: ...DM 54 Chimney Component List Dimensions 28 ...

Page 32: ...32 DM 54 Chimney System Lateral Support cont FIGURE 51 FIGURE 52 ...

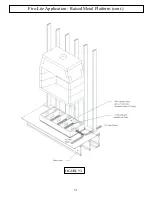

Page 51: ...51 Fire Lite Application Raised Metal Platform cont FIGURE 93 ...

Page 58: ...Notes 58 ...