17

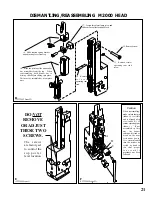

8. Push two face plate retaining clips (Index F)

outward while lifting face plate up, or remove

retaining clips to release face plate.

9. Position grip spring housing (Index G) between

tension pawl spring retainer (Index H) and

cutter housing (Index I).

10. Remove face plate (Index B) by sliding face

plate to the left and lifting up.

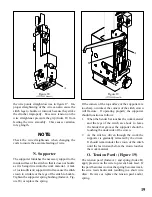

11. Remove the cutter operating slide (Index I,

Figure 15).

12. Insert a new cutter operating slide.

13. Reassemble

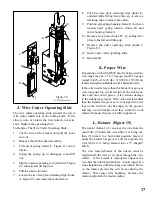

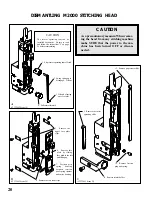

K. Proper Wire

Depending on which M2000 head is being used the

wire range may be: 25 to 30 gauge round; 24 gauge

round; 20x25 or 21x25 flat. 120,000 to 159,000 psi

tensile strength bookbinders wire should be used.

If the wire used is larger than the bender bar grooves

were designed for, it will fracture at the stitch cor-

ners and come out in pieces. Also, serious damage

to the stitcher may result. If the wire used is smaller

than the bender bar grooves were designed for, the

legs of the stitch do not fit snugly in the grooves

and may tend to buckle when they strike the work

material because they are not fully supported.

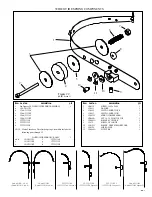

L. Rotator (Figure 15)

The rotator (Index J) (1) receives the wire from the

cutoff die, (2) holds the wire while it is being cut,

then (3) turns it to a horizontal position, moves it

under the bender bar grooves and (4) supports the

wire while it is being formed into a "U-shaped"

stitch.

The wire lead-in-funnel of the rotator must be

aligned with the wire as it comes through the wire

cutters. If the rotator is improperly aligned, the

wire hits the rotator and buckles. Adjust upper two

wire straighteners until wire slips past rotator. Burrs

on the rotator prevent the wire from entering the

rotator. This causes wire buckling. Remove the

rotator and polish the lead-in radius.

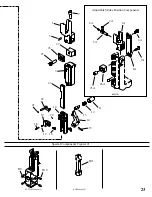

J. Wire Cutter Operating Slide

The wire cutter operating slide actuates the lower

wire cutter which acts as the cutting knife. If the

slide is worn or broken, the wire cutter is not actu-

ated. Replace the operating slide.

To Replace The Wire Cutter Operating Slide:

1. Cut the wire at the bracket and pull the loose

end out.

2. Remove the stitcher head assembly.

3. Lift end of spring (Index L, Figure 15) out of

rotator.

4. Swing the spring up to disengage it and lift

out.

5. Slip the rotator operating cam (Index M, Figure

15) forward and off the stud.

6. Pull the rotator forward.

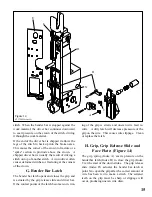

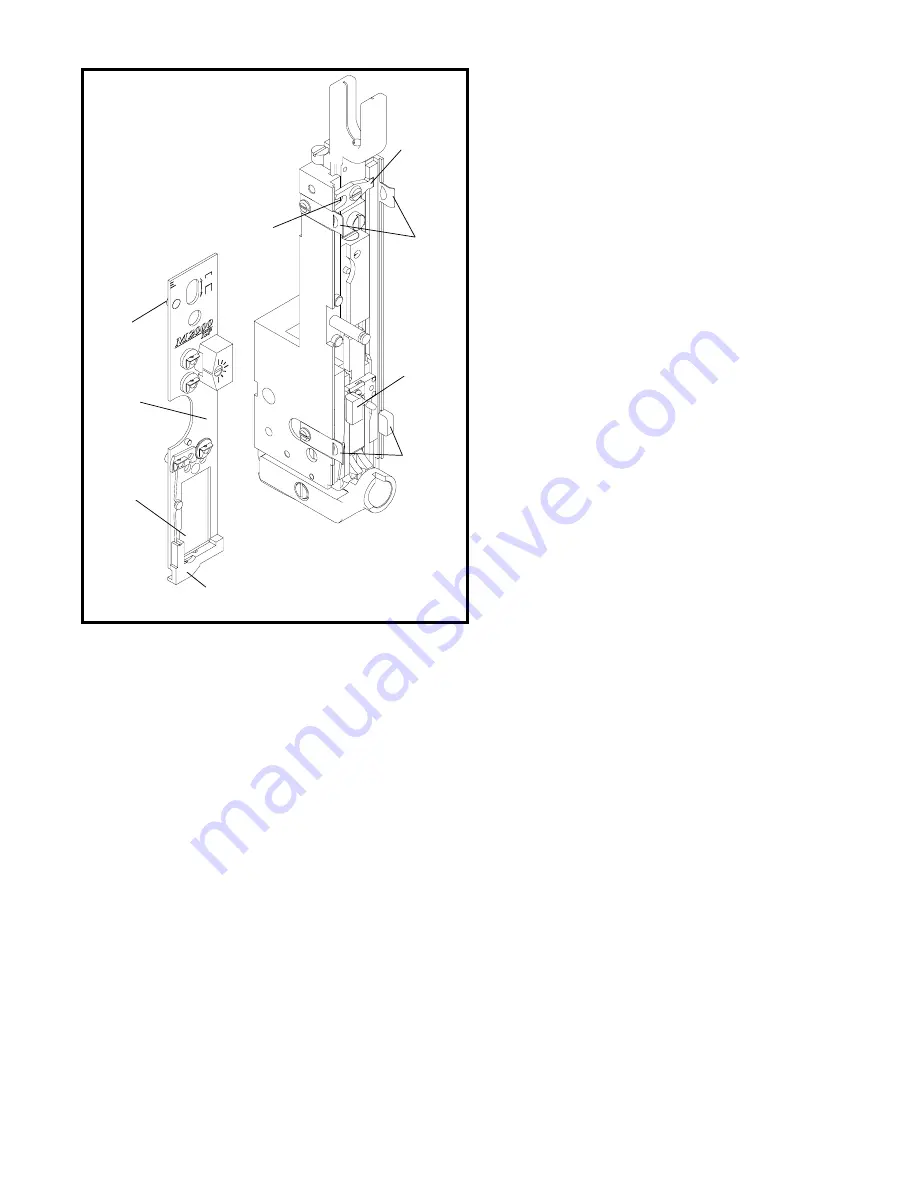

7. Loosen the two face plate retaining clips (Index

A, Figure 16) and rotate them downward.

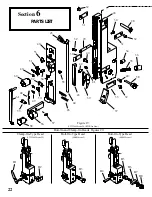

A

B

C

D

E

F

G

I

H

(CTTT2605 Scene 17)

Figure 16