5

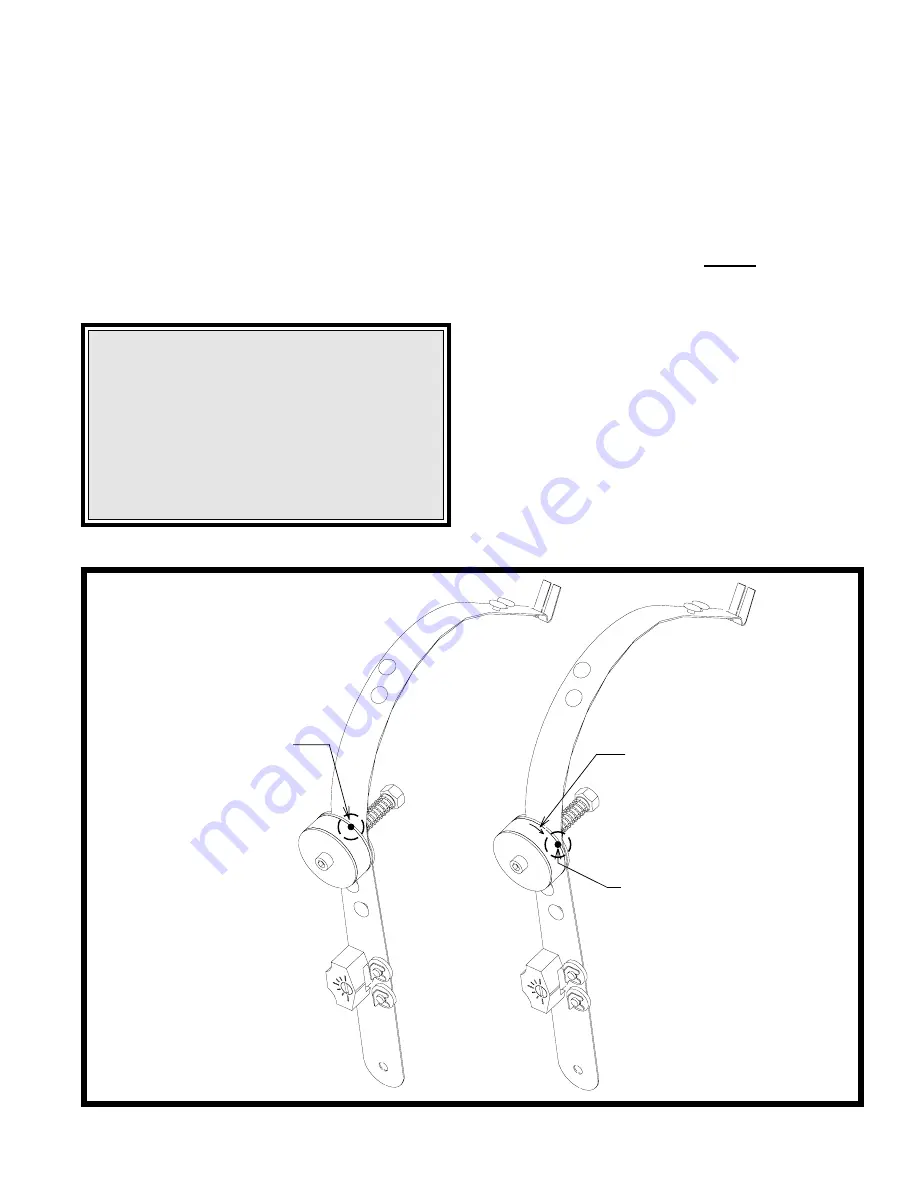

7. Adjust the upper wire straightener, beginning at

position shown, (Index E) so that the wire points

straight down. Adjust the lower wire

straightener, beginning at the 3:00 o'clock

position, (Index F) so that the wire (Index L)

feeds straight down.

8. Replace the rotator and rotator operating spring.

NOTE:

When changing coils or wire sizes, check

straighteners to insure proper wire feed.

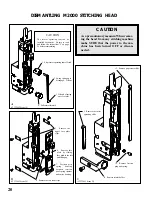

CAUTION

Do not operate stitcher until

operating instructions have been

read and understood-do not

operate stitcher at anytime without

work under the head.

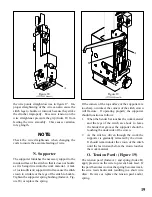

FELT WIPE PADS

LUBRICATION

AND MAINTAINANCE:

(FIGURE 2)

IMPORTANT! In order for the stitchers to operate

properly, the felt wire wipes

MUST

be rotated and

dampened with SAE 20W oil before each new spool

of wire (50,000 to 70,000 stitches). Replace felt

pads when they become so dirty that they cannot be

rotated to a clean spot.

Figure 2

Dirty area of pads has been

slightly rotated so that a clean

area of pads can be used for the

next wire spool.

Rotate

1. After every wire

spool, rotate the

dirty area of the

pads slightly so that

a clean area can be

used for the next

wire spool.

(CTTT2605 Scene 7)

2. Dampen both pads

(about 30 to 40

drops) using an SAE

20W oil.