T

he

reference

in

surface

TreaTmenT

International

Surface

Technologies

i s t s u r f a c e . c o m

12

DCM600 to 1800 - Instruction Manual

attention

all maintenance must be done with the electric current turned off and locked label. the air supply

must be closed, empty, locked and tagged. Failure to do this, you could be seriously injured

following an electric shock to the activation of a componen

t.

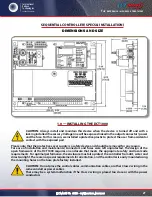

adJustMents (Cont’d)

PreVentiVe MaintenanCe

Settings

Process:

Value displayed during operation of the fan (inches of water restriction cartridges)

last output

: Number of active solenoid (this value can not be changed because the system auto-detects

the number of active coil connected to the card)

time off:

downtime between each pulse (value 10 seconds)

ON Time: Time pulse valves (value 250 milliseconds)

High limit:

The value to which the cleanup will begin (value between 2.5 and 3.5)

low limit:

The value to which the cleaning will stop automatically (value between 1.5 and 2.5)

High alarm:

Value must be reached to activate alarm (High limit value 2)

Low Alarm: Value must be reached to activate alarm (value = 0)

Cycle delay:

This value is to operate in manual mode (value = 0)

down time cycles

: This value is to operate in manual mode (value = 0)

auto alarm reset

: This value is to operate in manual mode (value = 0)

Always wear a properly fitted and maintained and goggles when cleaning the hopper tray. Failure to

properly protect yourself, you may develop serious respiratory diseases and inherit your eyes. Toxicity and

health risks vary by the type of abrasive and dust generated by sanding. Identify the material removed by

sanding and you pick the Material Safety Data Sheet of the abrasive used.

Daily

with the fan off, drain the base of the hopper dust. If your dust collector is equipped with a Barrel emptying

will be needed.

Weekly

with the fan, check out the fan, the dust should not escape from the fan.