T

he

reference

in

surface

TreaTmenT

International

Surface

Technologies

i s t s u r f a c e . c o m

26

DCM600 to 1800 - Instruction Manual

As with traditional Dwyer products, the Dwyer DCT1000 was designed so that it is easy to use, thus allowing

for a quick and easy start up for your dust control applications. The contents inside this installation and

operating manual will guide you through the features of the DCT1000 and how they can be applied to get

the most out of your dust control requirements.

Thank you for purchasing the sequential

controller DCT1000. You have selected a

model of its kind in the field of controller

that will provide years of operation with

high reliability.

Sequential Controller DCT1000 has been

designed for use with pulse jet type dust

collectors for cleaning applications on

demand or continuously.

The continuous cleaning applications

require no external inputs and can be

used depending on demand through the

use of the functionality of cycle time.

For on-demand applications, the pressure

modules (DCP100A/200A) optional can be

used to enjoy all the features of DCT1000,

or switch to external pressure (eg Dwyer

Photohelic ®) can be used to control high

/ low limit.

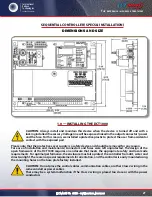

sPeCiFiCations

•

Output Channels: 6, 10, & 22 channels. Expandable to 255

•

channels using DCT1122 & DCT1110 channel expander boards.

•

Power Requirements: 85 to 270 V AC, 50 or 60 Hz.

•

Solenoid Supply: 3 A maximum per channel.

•

Fuse: 3 A @ 250 V AC. Low voltage control circuitry is isolated from

•

the line voltage for system safety.

•

Temperature Limits: -40 to 140°F (-40 to 60°C).

•

Storage Temperature Limits: -40 to 176°F (-40 to 80°C).

•

On Time: 10 millisec. to 600 millisec. , 10 millisec. by steps.

•

On Time Accuracy: ±10 millisec. .

•

Off Time: 1 second to 255 seconds, 1 second steps.

•

Off Time Accuracy: ±1% of the value or ±50 millisec. , whichever is greater.

•

weight: 1 lb 3.0 oz (538.6 g).

•

Agency Approvals: UL, cUL.

SPECIfICAtIonS - InStAllAtIon AnD oPErAtInG

sequential Controller dCt1000 (sPeCs)