T

he

reference

in

surface

TreaTmenT

International

Surface

Technologies

i s t s u r f a c e . c o m

36

DCM600 to 1800 - Instruction Manual

3.1 restoring Factory defaults

The DCT1000 has been programmed with factory default values that meet most industry operating conditions.

In the event that you want to restore all of the parameters to the original factory default values:

(1) Return the master controller to the process mode.

(2) Press and hold both “UP” and “DOwN” buttons.

The display will indicate a 10 second countdown, at the end of which all parameters will be restored to factory

defaults. Releasing the switches prior to the end of the count will stop the process and no modification will be

made. Likewise, in each of the parameter setup modes, pressing and holding the “UP” and “DOwN” buttons

simultaneously will reset the individual default value, leaving other settings unchanged.

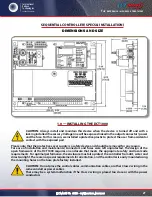

3.2 Power indicator

A power on LED indicator is provided at the center left edge of the board. This will be illuminated when the

power supply is operating properly. If the power LED is not illuminated, the primary power may be off or there

is a fault in the power circuit.

3.3 active Channel indicator

Located just above the solenoid terminations, you will find that each channel is provided with an LED that is

illuminated when the TRIAC switch is on. This allows a visual correlation between the channel being pulsed and

the operation of the solenoid.

3.4 Comm Check indicator

The Comm Check Indicator can be found in the upper right hand corner of the slave and master controller board

(just above the “out” terminal, a telephone style connector). This indicator is used for two purposes. First, on a

master controller a brief flash once per second is produced to indicate that the system is operating. Second, this

indicator is used to show when the communication check operation is performed on slave boards. The master

controller will check each of the slave boards at a rate of about one inquiry per second, starting with the slave

board connected directly to the master controller and ending with the last slave board in the chain. The master

controller will flash its Comm Check LED for about 250 millisec. each time it makes a communication check. The

external module selected for test will also flash its Comm Check LED for about the same time each time it is

interrogated. Observing this test sequence will indicate that the communication between boards is operational.

when a slave board powers up, the Comm Check LED will be illuminated continuously. It will be extinguished

when the master controller has initialized its communication channel. This indicator then shows that a master

controller is operating and that each slave board is responding properly on the daisy chain.

3.0 — MaintenanCe suPPort and diagnostiCs

3.0 — MaintenanCe suPPort and diagnostiCs