80

LUBRICATING SYSTEM

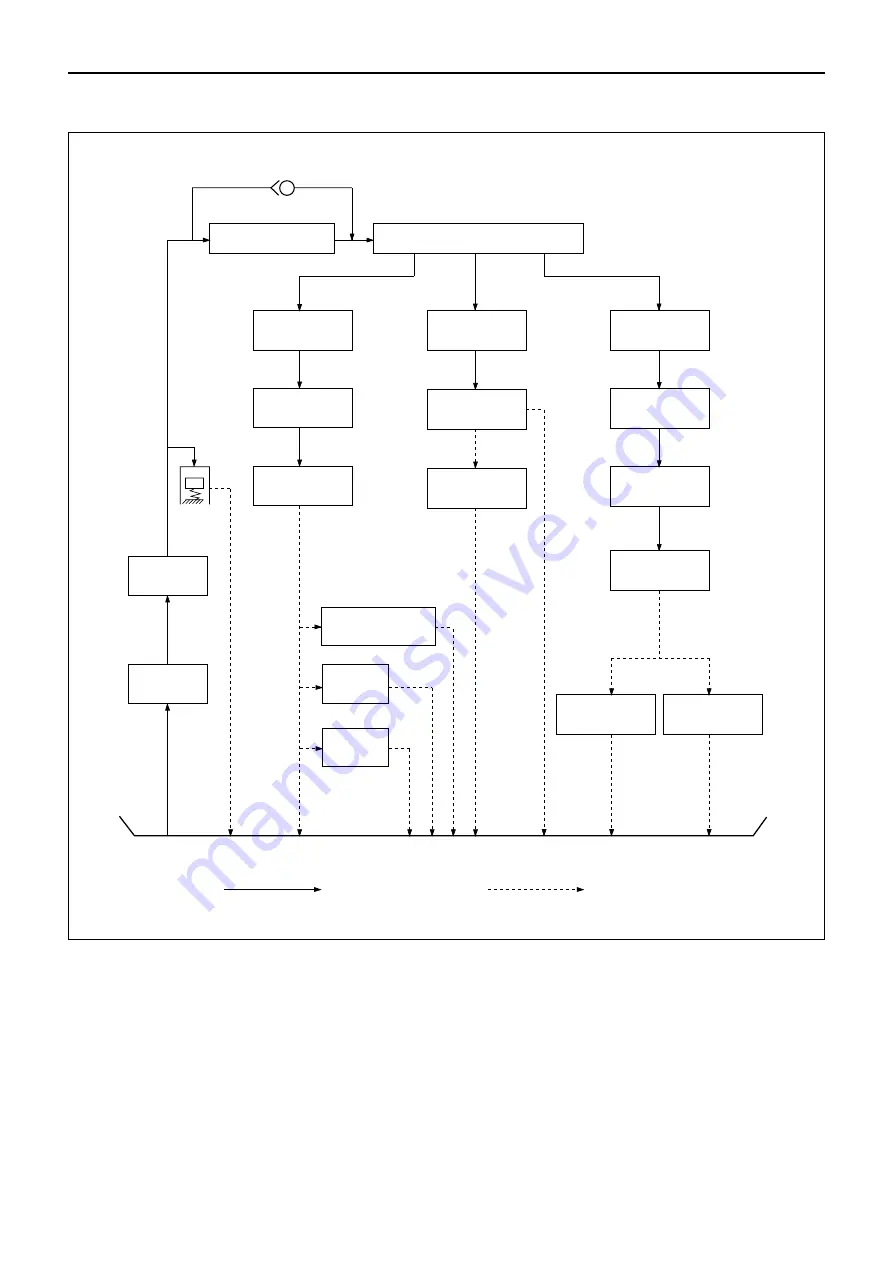

LUBRICATING OIL CIRCULATION DIAGRAM

Pressure feeding

Non pressure feeding

Oil pan

Valve opening pressure 98 kPa (1kgf/cm

2

)

Oil filter

Oil gallery

Main bearing

Crankshaft

Connecting rod

Idle gear bush

Timing gear

Governor

Cylinder head

Rocker arm

bracket

Rocker shaft

Rocker arm

Valve

opening

pressure

440 kPa

(4.5kgf/cm

2

)

Oil pump

Strainer

Piston

Injection pump

Piston

pin boss

Tappet

Valve stem end

Fig. 170

Summary of Contents for 4LE2

Page 1: ...INDUSTRIAL DIESEL ENGINE 4LE2 MODEL 2003 ISUZU MOTORS LIMITED WORKSHOP MANUAL ...

Page 8: ...GENERAL INFORMATION 5 APPEARANCE 1 MODEL 4LE2 1 Left side view 2 Right side view Fig 2 Fig 3 ...

Page 16: ......

Page 19: ...6 TURBOCHARGER N m kgf m ft lb 16 GENERAL INFORMATION Fig 16 19 28 1 9 2 9 14 21 ...

Page 29: ...MEMO ...

Page 36: ...ENGINE 33 Internal Parts 1 3 1 3 2 7 4 5 17 18 6 15 16 14 Fig 44 ...

Page 37: ...34 ENGINE Internal Parts 2 3 Fig 45 Do not pull out this bolt 20 13 12 9 10 11 8 19 Rear 21 ...

Page 38: ...ENGINE 35 14 1 14 2 15 Internal Parts 3 3 When provided with PTO Fig 46 ...

Page 64: ...ENGINE 61 Internal Parts 1 3 Fig 119 Rear 3 14 2 13 12 11 1 10 9 ...

Page 65: ...62 ENGINE 19 20 18 17 4 5 15 20 7 6 16 8 Internal Parts 2 3 Fig 120 ...

Page 66: ...ENGINE 63 8 1 8 2 7 Internal Parts 3 3 Fig 121 ...

Page 85: ...MEMO ...

Page 91: ...MEMO ...

Page 103: ...MEMO ...

Page 109: ...MEMO ...

Page 111: ...MEMO ...

Page 121: ...PRINTED IN JAPAN IDE 2330 ...