Green Heating Technology

26

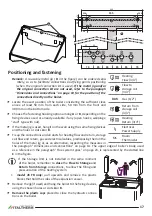

Inlet gas check

Remark:

The pressure should be measured at nomi-

nal input, so this test must be performed with the

burner ignited.

1.

Loosen (2-3 turns) the screw of pressure tapping

point for gas inlet

2

of the gas valve and insert the

manometer sensor;

2.

check that the measured pressure complies with

the inlet gas nominal pressure (see "Technical data"

on page 38).

3.

close the pressure tapping point

2

and

check the

absence of gas leaks

�

Max and Min pressure adjustment

1.

Loosen (2-3 turns) the screw of pressure tapping

point for gas outlet

1

of the gas valve and insert the

manometer sensor. Leave the silicon tube (coming

from the sealed chamber) inserted on the “Vent” 3;

2.

Activate the boiler to its maximum output not mod-

ulated, using the “Chimney-sweeper” function. Proceed as follows:

• the boiler should be electrically powered and set in Heating Only mode. Use the button

if

necessary;

• generate a heating request by activating the room thermostat;

Be sure that the heat produced by the boiler can be eliminated by the heating system (through

the radiators and/or radiant panels/floor systems).

• activate the boiler to its

maximum output not modulated (Qn)

, using the “Chimney-sweeper”

function, that activates by entering the technician menu and setting the parameter

12

to value

1

(see also "PCB parameters settings (technician menu)" on page 27);

3. wait at least 10 seconds

and verify that the measured pressure corresponds to the MAX value

indicated in the Technical data table >

Gas supply pressure

on page 39 or page 41, with regard

to the boiler model and gas type;

4.

extract one of the connectors

4

that supply the modulation coil; verify that the measured pres-

sure corresponds to the MIN value indicated in the Technical data table >

Gas supply pressure

on

page 39 or page 41, with regard to the boiler model and gas type;

5.

reinsert the connector

4

;

6.

if it is necessary to adjust the regulation, proceed as it follows, referring to the figure:

• take off the protection cap

C

;

• adjust MAX pressure acting on the nut

B

(10 mm). Turn clockwise to increase pressure, counter-

clockwise to decrease pressure;

•

extract again one of the connectors

4

;

• adjust MIN pressure acting on the screw

A

(with a 4 mm screwdriver), paying attention not to

contemporarily move the nut

B

. Turn clockwise to increase pressure, counterclockwise to de-

crease pressure;

Pressure tapping points:

1

outlet

2

inlet

3

equalization (VENT)